To open a pasta factory, it is a good idea in the current pasta market

You need to prepare a workshop of 50 square meters, which must be equipped with everything needed to prepare the pasta and sell the product itself.

Then you need either a pasta line or a macaroni line, in fact the two processes are similar.

One line can be used for the production of two or more products.

In the current pasta market environment, a small pasta factory can be managed by a family or by 2 - 3 people.

Barilla , Store brands , Mueller's , Ronzoni , Creamette , Buitoni ,American Beauty ,Skinner, San Giorgio pasta brand manufacturer can reach a profit of 30% of the raw material !

This income is the average for pasta and macaroni businesses.

The 2022-1 Macaroni Production Machine has reasonable design and superior performance. These equipments are developed by our macaroni industry designers in combination with many years of macaroni production experience.

The production process of macaroni equipment is rigorous and serious. Every equipment detail has been carefully considered and checked at multiple levels, so the final product is very ideal.

The macaroni production line can produce a variety of foods, such as pasta, shell potato chips, white fungus shaped potato chips, pentagonal potato chips, cat ear shaped potato chips, macaroni, rice, chrome-plated noodles, etc. Different molds can be used to produce different foods. shape.

We can also make macaroni pasta models according to customer requirements to meet more customer needs.

Loyal is a professional manufacturer of macaroni equipment and pasta equipment.

The dedicated pasta production line technical team is here to help you. Solve any type of mechanical equipment and process problems in pasta production workshops.

If you buy our macaroni equipment and pasta equipment, we will provide you with the most reasonable price,

In the food manufacturing industry, to ensure that you save costs while bringing you the greatest economic benefits.

If you have any requirements for macaroni production process and pasta production process, please contact us as soon as possible. In addition, our service is also very good, whether it is pre-sale, in-sale, after-sale or technical service, it is the best quality.

We look forward to your visit.

-----------------------------------------------------------------------------------------------

What Is Difference Between Pasta And Macaroni?

How Is Italian Pasta Made?

How Is Pasta Made In Industry?

What Is The Process Of Pasta?

Next Topic !!

A Complete Buying Guide For The Macaroni Production Machine:

1. What is difference between pasta and macaroni?

Macaroni is a type of dried pasta that looks like a narrow tube. Although it is an Italian delicacy, it is famous all over the world. It is made from durum wheat and no eggs are used in its preparation. As macaroni is a type of pasta, it is also made from dough, from which pasta is also made.

2. Brief introduction of macaroni production machine

The macaroni production line mainly uses potato starch, corn starch, flour, etc. as raw materials, using a screw extruder and a unique extrusion molding process to produce short pasta and macaroni with various shapes that are popular on the market, such as crisp peas, shells, spirals, etc. Square tube, round tube, and wave shapes.

The macaroni making machinery adopts the most advanced technology in the industry to mix water and flour more fully. It can complete raw material mixing, extrusion, molding, drying, cooling, and packaging in one step. The entire production line is produced in an assembly line with very high automation. One or two people can complete the processing process, which can greatly save manpower and improve work efficiency.

3. Benefits of macaroni production machine

(1) The macaroni production line has reasonable design, high degree of automation and precise control of extrusion parameters.

(2) The main engine is equipped with high and low pressure screws, which increases the use range of raw materials, reduces costs and improves product quality.

(3) The screw is made of alloy steel and special technology, the screw life is longer, and the modular system structure is adopted, which can be combined at will. To

(4) The visualized automatic temperature control system makes the temperature control more intuitive, which is convenient for observation during operation and is clear at a glance.

(5) The whole machine is made of stainless steel, beautiful and atmospheric, and has a long service life. There are no pollutants or three wastes during the processing. The final product is high-quality and healthy, with excellent taste and rich nutrition.

4. Limitation of macaroni production machine

The macaroni making machine has many advantages, but it also has some shortcomings. For example, because the production line uses very advanced machines and all parts are excellent, compared with the previous equipment, the cost may be higher. Some, the cost is higher, but its performance is very superior, and the benefits brought by it are also higher.

In addition, because the production line involves a lot of equipment, although the degree of automation is high, there are many points that need to be paid attention to during operation. You may not pay attention to a certain equipment failure will cause the entire production line to stop running, so it is in use. During the process, carefully check the working condition of the equipment.

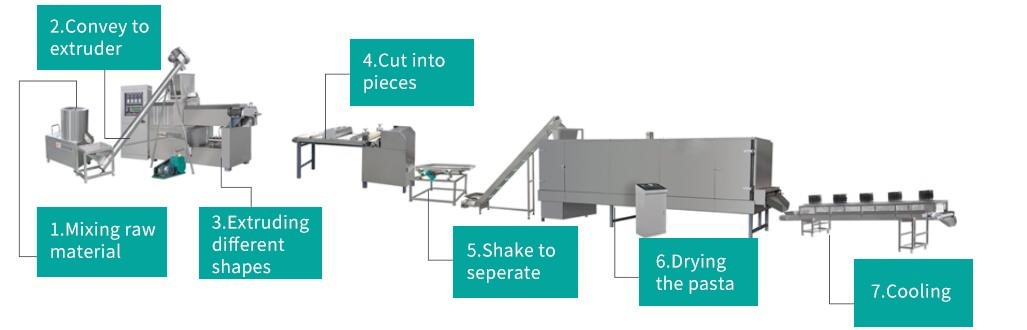

5. How macaroni production machine Works

The raw materials are mixed with water in a mixer, and the mixed flour is fed into the macaroni extruder by a vertical screw conveyor. The cylinder wall of the extruder is double-layered. The cavity is cooled by water and installed at the outlet end of the cylinder liner. There is a molding die. The wet flour is extruded from the die hole and rotated and cut into wet macaroni. The product automatically falls into the pre-drying machine. After pre-drying, it automatically falls into the far-infrared dryer. After drying, it automatically falls into the cooling device. After cooling, it is packaged The machine is packaged as a finished product.

6. Parts of macaroni production machine

(1) Feeder: Installed on the main engine, screw feeding, the quantity is adjustable, the system includes engine, screw, mixer and machine frame.

(2) Extruder: Use mixing, cutting, extrusion and other processes to make the material mature at low temperature, and strictly control the temperature of the roller and screw to meet the material requirements.

(3) Cutting machine: The shelf is fixed on the head of the mold and rotates and cuts the material under the push of the pulley.

(4) Heating machine: Divided into five zones, the heating temperature can be adjusted individually.

(5) Transmission system: The power of the main engine is transmitted to the screw through the V-belt and reducer.

(6) Control system: It can centrally control all parts of the host, which is the key to the production line.

(7) Vacuum pump: For macaroni, the biggest problem is that there are bubbles and air in it. With a vacuum pump.