Features Of Puffed Food Which Produced By Twin Screw Extruder Puffed Food Making Machine

Puffed food has the following characteristics:

1. The preservation rate and digestibility of nutrients are high.

The starch in the cereal raw materials is quickly gelatinized during the full automatic puffing snacks processing line, which significantly increases the hydration rate of protein and carbohydrates. The gelatinized starch will not age after being placed for a long time. The protein-rich plant materials are extruded and expanded at high temperature for a short time in the industrial puffed food extruder machine, the protein is completely denatured, and the tissue structure becomes porous, which is beneficial to contact with human digestive enzymes, thereby improving the utilization and digestibility of protein.

The starch in the cereal raw materials is quickly gelatinized during the full automatic puffing snacks processing line, which significantly increases the hydration rate of protein and carbohydrates. The gelatinized starch will not age after being placed for a long time. The protein-rich plant materials are extruded and expanded at high temperature for a short time in the industrial puffed food extruder machine, the protein is completely denatured, and the tissue structure becomes porous, which is beneficial to contact with human digestive enzymes, thereby improving the utilization and digestibility of protein.

2. The puffed snacks products with better nutritional value and functional characteristics.

When using extrusion technology in the industrial corn puffed food production line to process foods with grains as raw materials, additives such as amino acids, proteins, vitamins, minerals, food colorings and flavors can be evenly distributed in the extrudate and irreversibly combined with the extrudate, which can achieve the purpose of strengthening food. Since the extrusion is performed at high temperature instantaneously, the loss of nutrients is small.

3. Improve food quality and easy storage.

The use of commercial corn puffing food making machine can make the originally rough structure become bulky and soft, increasing the color, fragrance and taste of food. Therefore, the puffing technology is conducive to the fine production of coarse grains, improves the quality of the food, and makes the food have a unique flavor of light weight, crispness and strong fragrance.

In addition, the high temperature and high pressure treatment of puffed food can kill microorganisms and inactivate enzyme activity. At the same time, the moisture content of the puffed food is reduced to less than 10%, which limits the growth and reproduction of microorganisms, which is conducive to improving food Storage stability.

4. It is convenient to eat, and there are many varieties.

Adding different auxiliary materials to raw materials such as grains, beans, potatoes or vegetables, and then extruding them to produce a wide variety of nutritious puffed foods.

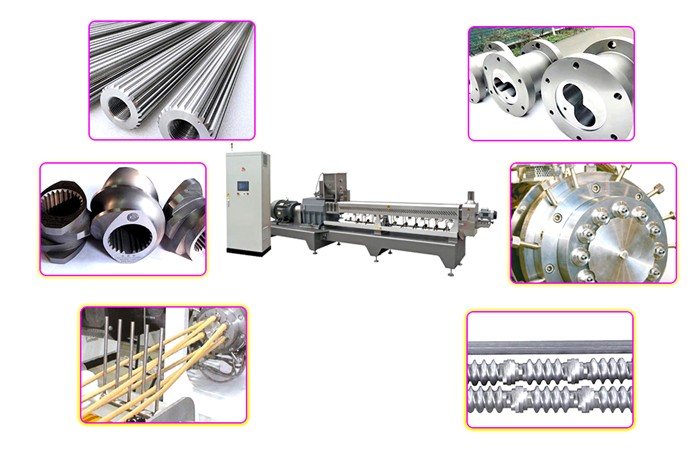

5. Simple puffed food production equipment, small floor space, low energy consumption and high production efficiency.

The equipment used for processing puffed food is simple, and the structure is unique. It can be combined or replaced easily and quickly to become a multi-purpose system. The equipment for processing unit weight products requires a small area. It can also save the consumption of electricity, steam, and water required to produce a unit weight of cooking products. The labor productivity is high and the processing cost is low.

6. The process is simple and the cost is low.

The processing of cereals generally requires processes such as mixing, forming, baking or frying, sterilization, drying or crushing, and equipped with various equipment; while the extrusion method is used to process cereals, because the extrusion process Finish mixing, crushing, sterilization, compression molding, dehydration and other processes to make expanded products or expanded and structured products, which significantly shortens the production process and reduces the production cost. At the same time, it can save more than 20% of energy. Therefore, it is a new energy-saving process.