What Is The Operation And Maintenance Method Of Extruded Machinery?

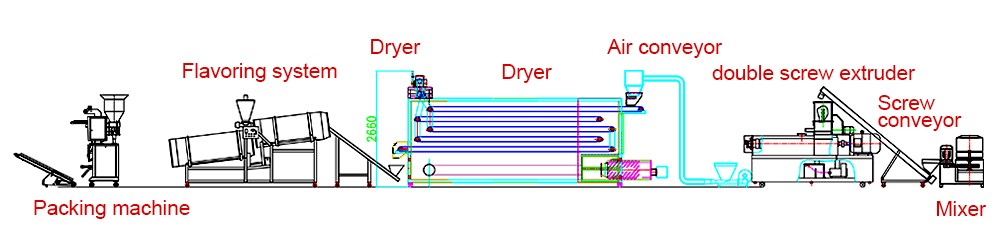

Feed puffing machinery is a new generation of puffed food production equipment developed by Shandong Loyal on the basis of absorbing advanced technology of similar foreign equipment. Its technical performance and product quality have reached the advanced level of similar foreign equipment. The puffed extruder making production line is extruded from ingredients. The molding sandwich is cut and baked and sprayed to the finished product at one time, which is fully automated. The puffing snack processing line has many models, flexible equipment configuration, a wide range of raw materials, a wide range of products, and simple operation. By changing molds and production processes, pillow shapes can be produced Cylindrical round pie-shaped rectangular sandwich products, suitable for various food manufacturers.

Features Of Feed Extruder Machinery

|

1 |

The international advanced pelletizing structure adopts the cutting mode of the cutter shaft positioning spring to realize stepless speed change, and can cut the output into the required length product at will. |

|

2 |

The design is novel and unique, the structure is simple, easy to install and disassemble, and easy to operate. |

|

3 |

The screw and the screw are made of special wear-resistant, high-temperature and high-humidity material 38 chromium molybdenum aluminum, which is first quenched and tempered and then heat-treated to form, which has the advantages of wear resistance and long life. |

|

4 |

It is equipped with a unique pressurizing die device to ensure the output and quality of the feed; the electric heating device improves the feed expansion rate. |

|

5 |

The spindle bearings are combined with Japanese Seiko and Swedish SKF bearings to ensure the safety and reliability of the extruder |

|

6 |

The main motor adopts high-quality Y series three-phase motor to ensure strong power; the reducer is matched with the main motor to ensure sufficient power; |

Manual of Puffing Snack Extruding Machinery

1. The pellet extruder is suitable for raising fish, shrimps, frogs, pigs, ducks, etc. The extruded feed produced by the extruder is extruded, soft and cooked, with complete protein and high nutrients, and floats on the water for a long time without wasting feed. Adding trace elements to promote fish The class grows quickly.

2. Add the wheat husk, corn flour, bean and fish meal, etc., plus the compound premix, add 10-17 kilograms of water per kilogram according to the formula, and put it into the mixer to mix evenly, about 3-5 minutes, start the mixer and stir the dragon, The material is pumped into the storage barrel, and the storage barrel is pumped into the mouth of the extruder. Pay attention to control the closing of the storage barrel. From small to large.

3. Cutting part: The size of the cutting granule is determined by the discharge hole. If you want to expand, it is generally 4.5 cm, and the holes are opened 4-5. For high output, 10-15 holes can be opened without expansion, and the small motor can be adjusted back and forth. , The knife should be in a smooth direction, and it is best to use 3 to 5 catties of feed and more water to start when cutting.

4. After each material is finished, disassemble the cutting part of the front section, use the tool hook to immediately disassemble the nut on the extruded head, and then start the motor to flow out the excess feed in the machine, and clean the nut orifice.

Maintenance Method Of Feed Puffing Machinery Failure

1. There is a strange sound in the body, and the bearing is rotten and worn out and lacks oil. Maintenance method: disassemble the large pulley, the front discharge port part, hammer out the main shaft forward or backward. Insert the rear axle bearing first, and fix the rear cover screw. , Re-enter the front bearing, replace the oil seal, add base lubricant, and do not add engine oil.

2. The screw (propeller) generally can produce about 100,000 kilograms, it will wear out, the output will decrease, and it will not expand. Solution: Replace the new screw (propeller) sleeve is more durable than the propeller. Generally, the new propeller is equipped with the old sleeve. The new set is equipped with the old shaft (propeller).

3. When the discharging hole is too large, the other hole should be replaced. 4 For other reasons, the discharging nut cannot be disassembled, and the sleeve can be disassembled with a tool hook, clamped with a vise, and disassembled by heating with oxygen.