What Are The Main Uses Of The Feed Extruder Machine

With the continuous development and progress of society, more and more feed extruders are used. What are the main uses of feed extruders? The following Shandong loyal industrial company will explain the main uses of feed extruders machine:

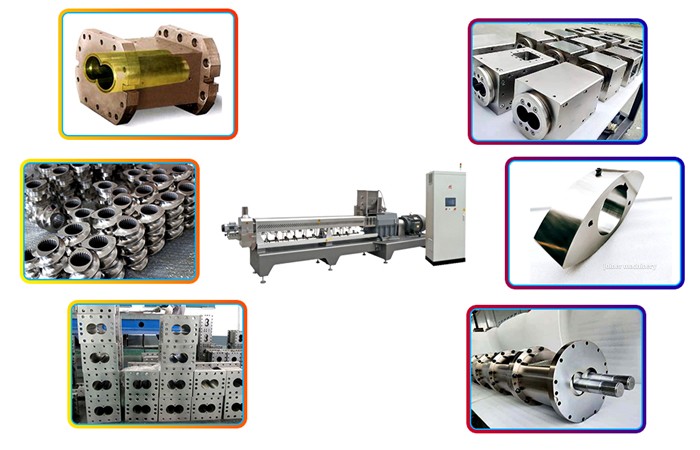

1. The twin screw pet feed extruder has novel design, compact structure, high production efficiency; reliable work, sturdy and durable, low failure rate, convenient operation and maintenance; simple and convenient use, stable transmission, and low noise.

2. The main components of the fish feed extruder machine are made of special alloy materials by heat treatment, and have a long service life. Only a few domestic manufacturers use special wear-resistant alloy precision casting. Although the extruder machine manufacturer is 2-3 times higher than conventional materials, the overall feed extruder cost is greatly reduced. Generally, manufacturers who have designed and produced extruders for more than 10 years are more reliable.

3. The puffing machine adopts dry puffing process, adopts self-heating method, and does not need steam system, which is more in line with the actual needs of users.

4. The screw discharge nozzle of the fish feed extruder adopts a modular design, which is convenient to adjust and low in price; the screw design has a powerful self-cleaning function, and the screw groove can be purified by itself, so when changing the formula and product variety, there is no need to stop for cleaning. The screw has strong pumping effect, strong material stagnation and diffusion effect, fast advancing speed, relatively stable product quality.

5. The small extruder machine can be equipped with an automatic feeding system. The feeder is a horizontal conveying screw controlled by the latest switched reluctance speed motor in the world. The other end is connected with the puff extruder machine, which can be controlled by adjusting the feeding amount. Expanded output (quantitative feeding, and can effectively prevent material arching).

6. The cutting system, the independent cutting device and the machine body are connected conveniently and quickly. The cutting head with variable speed can easily adjust the cutting knife and the gap between the cutting knife and the template. Different templates can be prepared according to needs to ensure that all the required material diameter and length can produce products of different specifications and material shapes.

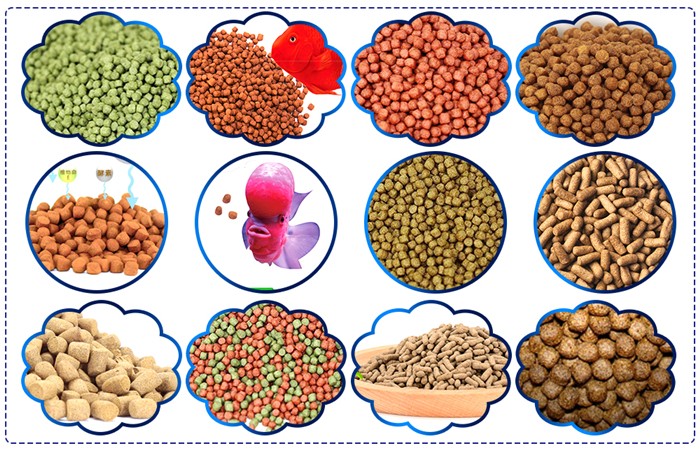

7. No binder is needed for processing floating feed, and it can maintain stability in water for more than 2 hours.