Nutritional Baby Rice Powder Food Craft Technical

Nutritional baby rice powder are supplementary foods that supplement infant nutrition when breast milk or infant formula cannot meet the nutritional needs of infants and during weaning. baby food powder manufacturers use twin-screw extruder process to produce rice as the main raw material, with white sugar, vegetables, Selective ingredients such as fruits, eggs, meat, etc., supplemented with calcium, phosphorus, iron and other minerals and vitamins and other baby cereal powder supplements for sale.

There are two baby rice cereal production processes: wet cooking process and dry puffing process, the differences are as follows

|

Wet cooking process for baby cereals powder |

Dry puffing process bab food powder |

|

Complex process |

Simple process |

|

Workshop staff |

Fewer operators |

|

The equipment covers a large area |

Small footprint |

|

Higher water and electricity consumption |

Reduce energy consumption, save energy and reduce pollution |

|

Long production cycle |

Shorten the production cycle |

|

Low absorption rate of nutrients |

High absorption rate of nutrients |

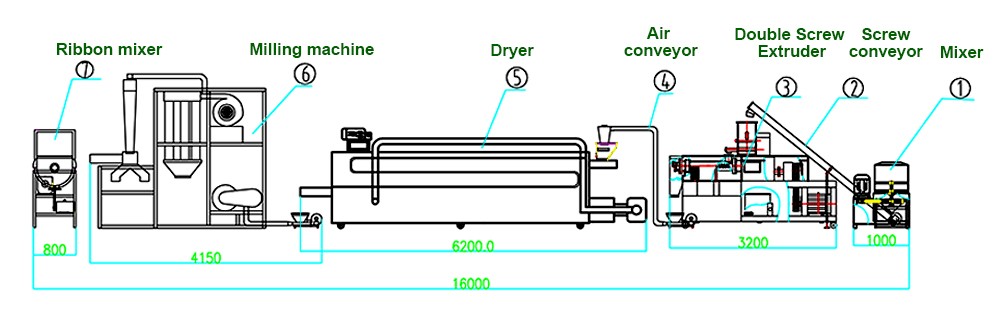

Extrusion infant cereal powder process: Rice → Crushing → Moisture adjustment → Extrusion → Drying → Crushing → Screening → Raw rice flour.

Nutritional baby rice powder parameters made from rice as the main raw material by extrusion and expansion method:

The moisture of the rice is 18%, the screw speed is 200 r/min, and the die temperature is 150 ℃. The puffed rice flour prepared with this parameter has the best solubility and taste.

The optimal ratio of instant infant nutrition rice flour is: puffed rice flour 65%, glutinous rice flour 7.4%, whole milk powder 8%, white granulated sugar powder 16%, whole egg powder 2%, lecithin 0.8%, monoglyceride 0.7%, BHT 0.1%. .

In nutrition powder process, the quality of the rice has an important influence on the quality of the rice flour. The fat in the rice will oxidize and deteriorate with the extension of storage time, forming fatty acids that penetrate into the endosperm and fill the amylose spiral ring, which makes starch gelatinization difficult and affects the quality of the rice flour. Solubility and

Analysis results of puffed rice and unpuffed rice in baby cereal powder processing line

|

Item |

Moisture /% |

Reducing sugar /% |

Starch α-Chemical degree /% |

|

Unexpanded rice |

13185 |

0185 |

——— |

|

Puffed rice |

6136 |

6116 |

98118 |

|

Item |

Protein /% |

Crude Fat /% |

Fatty Acid Value /mg KOH /100g |

|

Unexpanded rice |

8199 |

0181 |

18120 |

|

Puffed rice |

8186 |

0127 |

4104 |

Rice is degraded by squeezing puffed protein, and the macromolecule is cut into small molecular peptides and some amino acids, and the content of amino acids and peptides increases, which improves the human body's ability to digest and absorb proteins. The reduction of water content, fat content and fatty acid value in puffed rice is beneficial to the flavor and storage stability of puffed rice flour, and is conducive to the storage and processing of high-quality rice flour. So extrusion technology in food processing is best for Nutritional baby rice powder.

Effect of Single and Twin Screw Extrusion Method on Cooking Quality of Rice Flour Nutrition Compound Rice

The nutrient composite rice is prepared by the twin screw extruder process. Under the same formula, the heating water absorption rate, expansion rate, and composite rice grain texture characteristics are superior to the single screw extruder process. Set for 3~4min, the temperature drops to 60 ℃~70 ℃, and gently stir again, can form porridge with good dispersion and viscosity. The twin-screw process greatly improves the delicateness of the product. The fragrance is pleasant; the product strengthens the lecithin, a functional food ingredient, and further improves the nutritional and health care function of the product.