The Ultimate Guide To Green Tea Microwave Sterilizing Machine Updated 2025

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

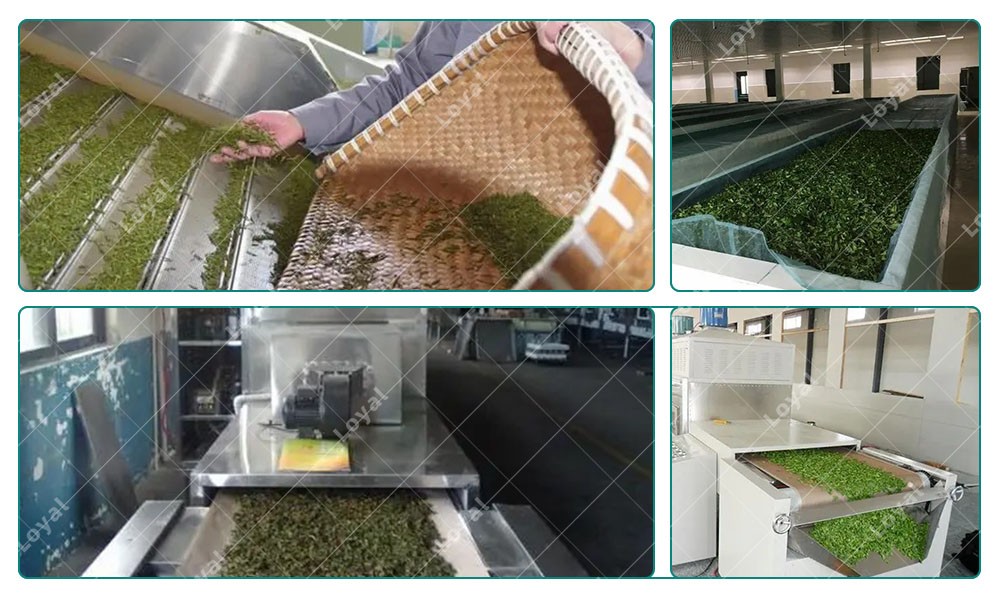

Introduction to Green Tea Microwave Sterilizing Machine

In recent years, the demand for green tea has surged globally, not only due to its refreshing taste but also because of its numerous health benefits. Green tea is rich in antioxidants, particularly catechins, which play a significant role in promoting health. However, maintaining the quality, safety, and nutritional value of green tea throughout its production and packaging process remains a challenge. This is where the Green Tea Microwave Sterilizing Machine has revolutionized the industry.

The traditional methods of sterilizing green tea, such as hot water steaming or sun-drying, have limitations when it comes to preserving the delicate flavors and nutrients of the leaves while ensuring the elimination of harmful microorganisms. Microwave sterilization, on the other hand, offers a more efficient and gentle approach. By utilizing electromagnetic waves, the Green Tea Microwave Sterilizing Machine provides a fast and uniform heating process, effectively sterilizing green tea while preserving its natural compounds, texture, and flavor profile.

The use of microwave technology in food sterilization has gained significant traction across various sectors due to its advantages over conventional heat treatments. When applied to green tea, this machine ensures that the leaves are treated with the least amount of heat, reducing nutrient degradation and preventing the loss of key antioxidants. Additionally, the microwave sterilization process is faster, requiring less energy and offering greater flexibility for large-scale production.

This innovative machine is crucial not only in ensuring the microbial safety of green tea but also in extending its shelf life without the need for harmful preservatives or additives. With consumer preferences shifting towards healthier and more natural products, the Green Tea Microwave Sterilizing Machine has become an indispensable tool in modern green tea production, providing manufacturers with a safe, efficient, and sustainable solution.

How Green Tea Microwave Sterilizing Machine Works

The Green Tea Microwave Sterilizing Machine is a cutting-edge piece of equipment that leverages the power of microwave energy to effectively sterilize green tea leaves, ensuring the elimination of harmful microorganisms while preserving the natural flavors and nutrients of the tea. This machine uses electromagnetic waves, a form of energy that can penetrate materials, generating heat within the product itself. Below, we’ll break down the key steps and components of how this advanced sterilization process works.

1.Microwave Energy Application

Microwaves are a form of electromagnetic radiation that operates at a frequency specifically tuned for food processing. When green tea leaves are placed inside the Green Tea Microwave Sterilizing Machine, the microwave energy is emitted through specialized magnetrons. These magnetrons generate microwave radiation that penetrates the green tea leaves, causing water molecules within the tea to vibrate rapidly. This vibration generates heat, raising the temperature of the tea leaves from within, which effectively kills bacteria, yeasts, molds, and other harmful microorganisms that may be present.

2.Uniform and Efficient Heating

One of the primary advantages of microwave sterilization over traditional methods is the uniformity with which heat is distributed. Unlike conventional sterilization methods, which rely on external heat sources to gradually warm the product, microwave energy directly heats the water content inside the green tea. This results in a more uniform heating process, ensuring that each tea leaf receives an equal amount of sterilizing energy, reducing the likelihood of uneven sterilization and maintaining consistent product quality.

The Green Tea Microwave Sterilizing Machine is equipped with a sophisticated system of rotating trays or conveyors to ensure that the green tea leaves are evenly exposed to the microwave energy. This uniformity is crucial for maintaining the flavor, aroma, and overall quality of the tea, as well as ensuring that all harmful microorganisms are completely eradicated.

3.Temperature and Humidity Control

To preserve the delicate compounds in green tea, such as catechins and other antioxidants, it is essential that the sterilization process is carefully controlled. Modern Green Tea Microwave Sterilizing Machines are equipped with advanced sensors that monitor the temperature and humidity levels throughout the sterilization process. These sensors ensure that the temperature does not exceed a point where the quality of the green tea could be compromised, allowing the machine to sterilize the tea effectively without degrading its nutritional value.

This level of control makes microwave sterilization a highly desirable option for manufacturers looking to maintain the high quality and health benefits of their green tea products while ensuring the safety of consumers.

4.Reduced Processing Time

Traditional sterilization methods for green tea, such as hot water steaming or sun-drying, often require long processing times that can expose the leaves to prolonged heat, leading to the degradation of key nutrients and flavors. In contrast, the Green Tea Microwave Sterilizing Machine can complete the sterilization process in a fraction of the time. The high efficiency of microwave energy allows for rapid penetration and heating of the tea leaves, sterilizing them in just a few minutes without prolonged exposure to heat. This faster processing time not only improves the efficiency of production but also helps to lock in the natural compounds that contribute to the tea’s beneficial properties.

5.Energy Efficiency

Another key feature of the Green Tea Microwave Sterilizing Machine is its energy efficiency. Unlike conventional sterilization methods that rely on external heating elements or steam, which require significant energy inputs, microwave sterilization uses targeted energy to heat only the green tea leaves. This focused application of energy reduces energy consumption while achieving the desired sterilization results. As a result, food manufacturers can lower operational costs and reduce their carbon footprint, making this method an environmentally friendly option for green tea processing.

6.Automated and Scalable

The Green Tea Microwave Sterilizing Machine is typically designed with automation in mind, allowing manufacturers to integrate it seamlessly into their production lines. The system is often equipped with programmable settings that allow for precise control over the sterilization process, making it easier to scale operations. The automation ensures consistency in each batch, reducing human error and increasing overall production efficiency. Additionally, the machine’s scalability allows it to handle different quantities of green tea, from small-scale boutique producers to large-scale industrial operations.

Challenges and Considerations in Green Tea Sterilization

While the Green Tea Microwave Sterilizing Machine offers numerous advantages in terms of efficiency, safety, and quality preservation, there are also certain challenges and considerations that manufacturers must address when implementing this technology. Understanding these potential issues and preparing accordingly is essential for optimizing the sterilization process and ensuring the best results. Below are some of the primary challenges and considerations in the sterilization of green tea.

1. Uniformity of Sterilization

One of the primary challenges with any form of microwave sterilization is ensuring uniformity. Green tea leaves, depending on their size, moisture content, and shape, can absorb microwave energy in different ways, leading to potential inconsistencies in sterilization. If not properly addressed, this could result in some portions of the tea being inadequately sterilized, potentially leaving behind harmful microorganisms.

To mitigate this challenge, modern Green Tea Microwave Sterilizing Machines are designed with advanced rotating trays, conveyors, or specialized stirring mechanisms to ensure even exposure to microwave energy. However, manufacturers must still monitor and adjust the system to ensure that all tea leaves are evenly treated during the process.

2. Temperature Control

Green tea is a delicate product that can be easily compromised by excessive heat. The Green Tea Microwave Sterilizing Machine must operate within specific temperature ranges to preserve the tea’s flavor, aroma, and health benefits. Overheating can cause a loss of key antioxidants like catechins, which are responsible for the health benefits of green tea.

To address this concern, manufacturers need to ensure that the machine is equipped with precise temperature control systems. Modern sterilizing machines incorporate sensors that monitor temperature and humidity in real-time, but operators must carefully calibrate these systems to avoid overheating while still achieving effective sterilization.

3. Retention of Nutritional Quality

One of the primary selling points of green tea is its high concentration of antioxidants, vitamins, and other essential nutrients. These compounds are highly sensitive to heat and can degrade under prolonged exposure. Ensuring that the Green Tea Microwave Sterilizing Machine sterilizes the tea without significantly impacting its nutritional profile is a significant challenge.

To minimize nutrient loss, microwave sterilization should be done as quickly as possible, while maintaining optimal temperature and humidity control. The short processing times of microwave sterilization offer an advantage here, but manufacturers must continue to refine their processes to strike the right balance between sterilization and nutrient retention.

|

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine |

|||||

|

Model |

Size LWH(Can be customized according |

Output |

Dewaterability |

Sterilization |

Baking and Roasting capacity |

|

LY-10KW |

5000mm825mm1750mm |

≥10KW |

10KG/Hour |

100KG/Hour |

30-50KG/Hour |

|

LY-20KW |

8000mm825mm1750mm |

≥20KW |

20KG/Hour |

200KG/Hour |

60-100KG/Hour |

|

LY-30KW |

8500mm1160mm1750mm |

≥30KW |

30KG/Hour |

300KG/Hour |

90-150 KG/Hour |

|

LY-40KW |

10000mm1160mm1750mm |

≥40KW |

40KG/Hour |

40KG/Hour |

120-200KG/Hour |

|

LY-50KW |

12500mm1160mm1750mm |

≥50KW |

50KG/Hour |

500KG/Hour |

150-250KG/Hour |

|

LY-60KW |

13500mm1450mm1750mm |

≥60KW |

60KG/Hour |

600KG/Hour |

180-300KG/Hour |

|

LY-70KW |

13500mm1500mm1750mm |

≥70KW |

70KG/Hour |

700KG/Hour |

210-350KG/Hour |

|

LY-80KW |

13500mm1650mm1750mm |

≥80KW |

80KG/Hour |

800KG/Hour |

240-400KG/Hour |

|

LY-100KW |

16800mm1650mm1750mm |

≥100KW |

100KG/Hour |

1000KG/Hour |

300-500KG/Hour |

|

LY-150KW |

22400mm1850mm1750mm |

≥150KW |

150KG/Hour |

1500KG/Hour |

450-750KG/Hour |

|

LY-200KW |

27000mm1850mm1750mm |

≥250KW |

250KG/Hour |

2500KG/Hour |

750-1250/Hour |

|

LY-300KW |

32000mm1850mm1750mm |

≥300KW |

300KG/Hour |

3000KG/Hour |

900-1500KG/Hour |

|

Power Supply |

380V±10% 50Hz±1% Three-Phase Five-Wire |

||||

|

Microwave Output Frequency |

2450±50Mhz |

||||

|

Microwave Input Apparent Power |

≤168Kva |

||||

|

Microwave Output Power |

≥120Kw |

||||

|

Microwave Power Adjustment Range |

0-30Kw(Adjustable) |

||||

|

Ambient Temperature |

-5-40°C |

||||

|

Relative Humidity |

≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas |

||||

|

Transmission Speed |

0-10m/Min(Adjustable) |

||||

Recommended Company

Shandong Loyal Industrial Co.,Ltd. Is a Manufacturer Of Snacks Extruder Machine , Industrial Microwave Oven , Corn Flakes Production Line , And a Standing Director Of China Food And Drying Equipment Industry Association.

The Self-developed Twin-screw Extruder And Single-screw Equipment of Shandong Loyal Machinery Have Been Used In Production: Puffed Snack Food, Breakfast Cereal Corn Flakes, Fried Pasta, Bread Crumbs, Fruit Chips, Baby Food, Textured Soy Protein (tsp) Food, Fish Feed And Pet Food. a Variety of Snack Production Line Supporting Products.at The Same Time, The Batching, Drying, Flaking, Baking, Frying And Spraying Equipment Matching The Twin-screw Extrusion System Have All Achieved Independent Design And Production.

Our Extrusion System Is Widely Used In: Puffed Snack Foods, Breakfast Cereals, Vegetable Protein Meat Products, Nutrition Bars, Fortified Rice, Grain Nutrition Powder, Modified Starch, Bread Crumbs And Other Food Additives, Pet Food, Aquatic Feed, Biology And Chemical Industries.

Customer-specific Food Processing Plant Project Solutions

As one of the leading manufacturers of food processing equipment, we are always searching for new solutions that benefit our snack food customers. Our experienced frying engineers always find the optimal solution for your industrial batch and continuous frying system line application. That's why we also develop, design and produce custom fried snack production line.

Close collaboration with our customer is important to us even in the early development phase. No matter what the special requirements of instant noodles production line, snack food extruder machine, pasta production line application, we can develop a custom made food processing equipment to match your needs.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

In ovens or drying units, electric or gas can be used as heating sources.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

About packaging and after-sales service

Packing: Plastic Film Suitable For Ocean Carriage

Technical Support: The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved.

Service Team:We have a professional After-sale Service team including10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc.

After-sale Service available :1.Check & test before delivery 2.Instruction for installation 3.On site commissioning 4.Repair & maintenance

After the receipt the advanced payment, we will provide allocation chart at the buyer’s request. When effect the shipment, we’ll provide operation manual, etc. in English.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com