Everything you Need to Know About Dog Food Extruder Machine

Introduction to Dog Food Extruder Machine

Dog food extruder machines are essential equipment in the pet food industry, designed specifically for the production of high-quality dog food. These machines utilize advanced technology to process various ingredients into nutritious and flavorful dog food products. With the growing demand for premium pet food, understanding the role and functionality of dog food extruder machines is crucial for pet food manufacturers.

Understanding the Working Principle

Dog food extruder machines operate on the principle of extrusion, a process that involves the transformation of raw ingredients into a finished product by forcing them through a die under controlled conditions. The process begins with the mixing of ingredients, including meat, grains, vitamins, and minerals, to form a homogeneous mixture. This mixture is then fed into the extruder machine's chamber, where it is subjected to high temperature and pressure.

Inside the extruder, the ingredients undergo cooking and shearing, resulting in the formation of a viscous dough-like substance. As the material moves through the extruder barrel, it is compressed and heated, causing it to expand rapidly as it exits through the die. This expansion creates the desired shape and texture of the dog food product.

The extrusion process not only cooks the ingredients but also enhances their digestibility and nutritional value. Additionally, the high temperature achieved during extrusion helps to kill harmful bacteria and pathogens, ensuring the safety of the final product.

Dog food extruder machines are equipped with various features to control the extrusion process, including temperature, pressure, and screw speed. These parameters can be adjusted to achieve the desired product characteristics, such as shape, size, and density.

Types of Dog Food Extruder Machines

Dog food extruder machines come in various types, each designed to meet specific production needs and requirements.

One common type is the single-screw extruder. This machine features a single rotating screw that pushes the raw ingredients through a barrel. Single-screw extruders are suitable for producing a wide range of dog food products, including dry kibble and semi-moist treats. They are relatively simple in design and are often favored for their cost-effectiveness and ease of operation.

Another type is the twin-screw extruder. Unlike single-screw extruders, twin-screw extruders have two intermeshing screws that work together to mix, knead, and extrude the ingredients. This type of extruder offers greater flexibility in terms of recipe formulation and can produce a wider variety of dog food textures and shapes. Twin-screw extruders are commonly used in large-scale production facilities due to their higher throughput capacity and efficiency.

Additionally, there are specialized extruders designed specifically for producing certain types of dog food, such as treats or dental chews. These extruders may feature unique configurations and attachments tailored to the specific requirements of the desired end product.

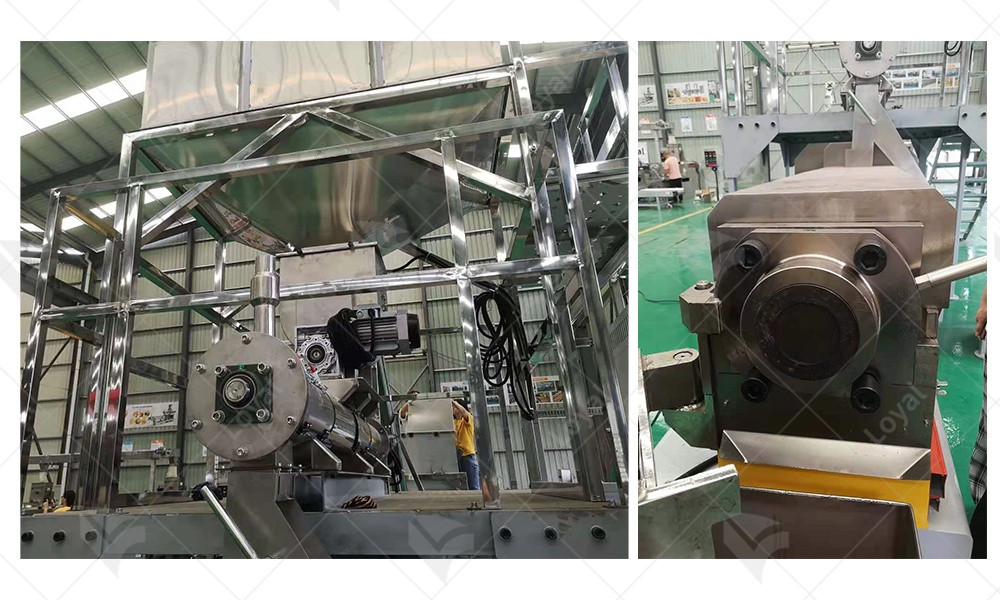

Key Components and Features

Dog food extruder machines consist of several key components that play essential roles in the extrusion process. One of the primary components is the barrel, which houses the extrusion screw or screws. The barrel is typically made of stainless steel and is heated to facilitate the cooking and shaping of the dog food mixture.

The extrusion screw(s) are responsible for conveying the raw ingredients through the barrel while subjecting them to heat, pressure, and mechanical shear. The design and configuration of the screws can vary depending on the desired product characteristics and processing parameters. Another critical component is the die, which determines the shape and size of the extruded dog food products. Dies come in various configurations, including round, bone-shaped, and star-shaped, allowing for customization of the final product.

Other features to consider when evaluating dog food extruder machines include the control system, which regulates parameters such as temperature, screw speed, and pressure, and the feeding system, which ensures a consistent flow of ingredients into the extruder. Some extruders may be equipped with cooling systems to rapidly cool the extruded products and prevent them from sticking together or becoming deformed.

Factors to Consider Before Purchasing

Before investing in a dog food extruder machine, several factors should be carefully considered to ensure that the chosen equipment meets the specific needs and requirements of the production operation.

One crucial factor is the production capacity of the extruder, which should align with the anticipated output volume. It is essential to evaluate the extruder's throughput capacity and efficiency to determine its suitability for the intended production scale.

Another consideration is the versatility of the extruder in terms of product flexibility and recipe customization. Depending on the desired range of dog food products, it may be necessary to choose an extruder that offers a wide range of processing capabilities and options for recipe formulation.

Factors such as ease of operation, maintenance requirements, and technical support services should be taken into account when selecting a dog food extruder machine. It is essential to choose a reliable manufacturer with a proven track record of producing high-quality equipment and providing excellent customer support.

Budgetary constraints and return on investment considerations should also be weighed against the features and capabilities offered by different extruder models. While it may be tempting to opt for the least expensive option, it is crucial to prioritize long-term reliability and performance to avoid costly downtime and repairs in the future.

Comparing Top Manufacturers

When comparing the dog food extruder machines from LOYAL and GEA (PAVAN), several factors come into play. Let's break down the comparison in a simple table format:

|

Aspect |

LOYAL Dog Food Extruder |

GEA (PAVAN) Dog Food Extruder |

|

Price |

Affordable |

Higher |

|

Capacity |

Medium to High |

High |

|

Durability |

Robust |

Dependable |

|

Technology |

Advanced |

Cutting-edge |

|

Customization Options |

Limited |

Extensive |

|

Customer Support |

Responsive |

Reliable |

When it comes to price, LOYAL dog food extruder machines tend to be more budget-friendly compared to GEA (PAVAN). However, GEA (PAVAN) machines offer higher capacity and cutting-edge technology, making them suitable for large-scale operations requiring high throughput.

LOYAL machines are known for their robust build and durability, while GEA (PAVAN) machines are dependable and offer extensive customization options to meet specific production needs. In terms of customer support, both companies excel, with LOYAL being more responsive and GEA (PAVAN) being reliable in providing assistance and technical support.

Overall, the choice between LOYAL and GEA (PAVAN) dog food extruder machines depends on factors such as budget, production capacity, technological requirements, and customization needs.

Maintenance and Cleaning Tips

Proper maintenance and cleaning of dog food extruder machines are crucial to ensure optimal performance and longevity. By following these maintenance and cleaning tips, you can prolong the lifespan of your dog food extruder machine and ensure consistent production of high-quality pet food products.Here are some tips to keep your machine in top condition:

1. Regular Inspection: Conduct routine inspections to check for any signs of wear and tear, loose parts, or damaged components. Address any issues promptly to prevent further damage.

2. Cleaning Schedule: Establish a regular cleaning schedule based on the frequency of use and the type of ingredients processed. Follow the manufacturer's guidelines for cleaning procedures and recommended cleaning agents.

3. Disassembly and Cleaning: Disassemble the extruder machine as per the manufacturer's instructions to access internal components for thorough cleaning. Pay special attention to areas prone to food buildup, such as the barrel, screws, die, and cutting knives.

4. Use of Cleaning Agents: Use approved cleaning agents and sanitizers suitable for food processing equipment to ensure effective removal of residues and bacteria. Rinse thoroughly with clean water after cleaning to prevent contamination.

5. Lubrication: Lubricate moving parts and bearings as recommended by the manufacturer to reduce friction and prevent premature wear. Use food-grade lubricants to ensure safety and compliance with food regulations.

6. Inspection of Seals and Gaskets: Check seals and gaskets regularly for signs of wear or damage. Replace any worn-out seals or gaskets to prevent leakage and maintain the integrity of the extrusion process.

7. Training and Safety: Provide training to operators on proper maintenance procedures and safety precautions when handling the extruder machine. Emphasize the importance of following safety protocols to prevent accidents and ensure a safe working environment.

Safety Precautions and Regulations

Safety precautions and regulations regarding dog food extruder machines are crucial to ensure the well-being of both operators and pets. Understanding and implementing these measures are essential for safe operation and compliance with industry standards.

Firstly, it's imperative to follow the manufacturer's guidelines and recommendations regarding the operation, maintenance, and cleaning of the dog food extruder machine. This includes proper training of operators to handle the equipment safely and efficiently. Regular inspections and maintenance checks should be conducted to identify any potential hazards or malfunctions promptly.

Operators should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and aprons to minimize the risk of injury during operation. Proper ventilation systems should be in place to control dust and fumes generated during the extrusion process, ensuring a safe working environment.

Adherence to relevant safety regulations and standards is essential. These regulations may vary depending on the geographical location and specific industry requirements. Compliance with regulations such as OSHA (Occupational Safety and Health Administration) standards in the United States or similar regulatory bodies in other regions is essential to avoid penalties and ensure workplace safety.

It's crucial to implement proper emergency procedures and protocols in case of accidents or equipment failures. This includes having fire extinguishers, first aid kits, and emergency shut-off mechanisms readily available and ensuring all personnel are trained in their use.

Future Trends in Dog Food Extrusion Technology

The field of dog food extrusion technology is continually evolving to meet the demands of pet owners and address emerging trends in the pet food industry. Several notable trends are shaping the future of dog food extrusion technology.

One prominent trend is the growing demand for customized and specialized pet food formulations. Pet owners are increasingly seeking tailored nutrition solutions for their pets, leading to the development of extrusion machines capable of producing a wide range of recipes with varying ingredients and nutritional profiles.

Tthere is a growing emphasis on sustainability and eco-friendliness in pet food manufacturing. This includes the use of environmentally friendly packaging materials and the adoption of energy-efficient extrusion technologies to minimize carbon footprint and reduce waste.

Advancements in digitalization and automation are revolutionizing the dog food extrusion process. Integration of IoT (Internet of Things) technology allows for real-time monitoring and control of extrusion parameters, enhancing efficiency and quality control.

The use of alternative protein sources such as insect-based or plant-based proteins is gaining traction in the pet food industry. Extrusion machines capable of processing these unconventional ingredients are being developed to meet the evolving dietary preferences of pet owners and address concerns regarding sustainability and animal welfare.

Overall, the future of dog food extrusion technology is characterized by innovation, sustainability, and a focus on meeting the diverse needs of pets and their owners. Keeping abreast of these trends will be essential for manufacturers to stay competitive in the dynamic pet food market.

FAQs: Frequently asked questions about Dog Food Extruder Machine

1. What is a Dog Food Extruder Machine?

A dog food extruder machine is a specialized piece of equipment used in the pet food industry to produce dry and semi-moist dog food products.

2. How do I maintain a Dog Food Extruder Machine?

Regular maintenance tasks include cleaning, lubricating moving parts, inspecting for wear and tear, and replacing worn components as needed, following the manufacturer's guidelines.

3. What safety precautions should be taken when operating a Dog Food Extruder Machine?

Safety precautions include wearing appropriate PPE, ensuring proper ventilation, following operational procedures, and adhering to relevant safety regulations and standards.

4. Are there regulations governing the use of Dog Food Extruder Machines?

Yes, regulations such as OSHA standards may apply, depending on the location and industry, to ensure workplace safety and compliance with quality and hygiene standards.

5. What are the future trends in Dog Food Extrusion Technology?

Future trends include customization, sustainability, digitalization, and the use of alternative protein sources to meet evolving consumer preferences and industry demands.

6. Who are some reputable manufacturers of Dog Food Extruder Machines?

Reputable manufacturers include (insert examples here) who offer a range of reliable and efficient extrusion solutions for the pet food industry.

References

1.Food Processing: This website offers comprehensive coverage of food processing equipment, technologies, and industry news. (https://www.foodprocessing.com/)

2. Packaging Digest: Packaging Digest provides insights into food packaging machinery, trends, and innovations. (https://www.packagingdigest.com/)

3. Food Engineering: Food Engineering offers resources on food manufacturing equipment, automation, and processing solutions. (https://www.foodengineeringmag.com/)

4. ProFood World: ProFood World covers the latest developments in food production technology, including machinery and equipment. (https://www.profoodworld.com/)

5. Food Manufacturing: Food Manufacturing provides information on food processing equipment, technology, and industry trends. (https://www.foodmanufacturing.com/)