The Ultimate Pet Food Equipment Guide to 2024

Cutting-Edge Innovations in Pet Food Equipment

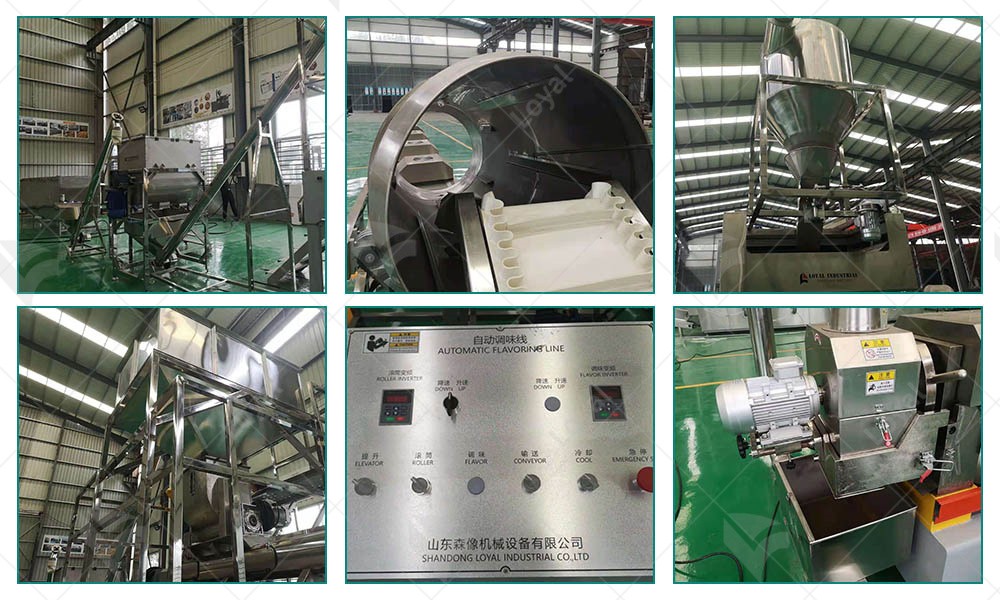

In recent years, the pet food industry has witnessed remarkable advancements in equipment technology, driven by the growing demand for high-quality and nutritious pet food products. One of the most significant trends in pet food equipment is the integration of cutting-edge automation and robotics systems into the manufacturing process. These technologies streamline production, enhance efficiency, and ensure consistency in product quality.

Furthermore, the development of sophisticated sensor technologies has revolutionized the way pet food equipment operates. These sensors enable real-time monitoring of various parameters such as temperature, moisture levels, and ingredient proportions, allowing for precise control and adjustment of the manufacturing process. As a result, manufacturers can produce pet food products that meet stringent quality standards and nutritional requirements with unparalleled accuracy.

Moreover, the advent of advanced materials and engineering techniques has led to the design of pet food equipment that is not only more durable and reliable but also more hygienic and easy to clean. Stainless steel, for example, is widely used in the construction of pet food processing machinery due to its resistance to corrosion and bacterial growth, ensuring the safety and integrity of the final products.

Revolutionary Advances in Pet Food Processing Machinery

The pet food processing machinery industry has undergone a revolution in recent years, driven by a combination of technological advancements and changing consumer demands. One of the most significant developments in this field is the adoption of advanced extrusion technology for the production of pet food products. Extrusion allows for the precise control of ingredient proportions and texture, resulting in products that are not only nutritionally balanced but also palatable and appealing to pets.

Another revolutionary advance in pet food processing machinery is the integration of novel processing techniques such as freeze-drying and air-drying. These methods preserve the natural flavors and nutrients of the ingredients while extending the shelf life of the final products without the need for artificial preservatives. As a result, pet owners can provide their pets with wholesome and nutritious food options that closely resemble their natural diet.

Furthermore, the development of customized processing solutions tailored to the specific needs of different pet food manufacturers has been instrumental in driving innovation in this industry. From compact, high-speed machines for small-scale producers to large-scale production lines capable of handling a wide range of ingredients and formulations, manufacturers now have access to a diverse array of equipment options to suit their unique requirements.

Unparalleled Precision: Engineering Pet Food Equipment

Precision engineering plays a crucial role in the design and operation of pet food equipment, ensuring consistency, efficiency, and quality in the manufacturing process. One key area where precision engineering has made significant strides is in the formulation and mixing of ingredients. Modern pet food mixers are equipped with advanced technology that allows for precise control of ingredient proportions and distribution, resulting in homogeneous blends that meet the nutritional requirements of pets.

Moreover, precision in temperature and moisture control is essential for achieving optimal cooking and extrusion conditions in pet food processing. State-of-the-art equipment is equipped with sensors and automated control systems that monitor and adjust these parameters in real-time, ensuring that the final products are cooked or extruded to perfection, with the right texture, flavor, and nutritional content.

Furthermore, precision engineering extends to the packaging and labeling of pet food products, where accuracy and consistency are critical for ensuring compliance with regulatory requirements and consumer expectations. Advanced packaging machinery incorporates features such as automatic weighing, sealing, and labeling, minimizing errors and maximizing efficiency in the packaging process.

Overall, the unparalleled precision achieved through engineering pet food equipment not only enhances the quality and consistency of pet food products but also contributes to the overall efficiency and competitiveness of the pet food industry. By leveraging the latest advancements in technology and engineering, manufacturers can continue to meet the growing demand for high-quality and nutritious pet food products while driving innovation and growth in the market.

Unprecedented Efficiency: Optimizing Pet Food Production Machinery

Pet food production demands efficiency at every step to meet the growing demand for high-quality pet nutrition. This requires optimizing pet food production machinery to streamline processes, minimize waste, and maximize output. Manufacturers are constantly innovating to achieve unprecedented efficiency in pet food equipment, integrating cutting-edge technologies and advanced engineering solutions.

Furthermore, advancements in automation play a crucial role in optimizing pet food production machinery. Automated systems allow for precise control and monitoring of various parameters such as temperature, moisture content, and ingredient ratios, ensuring optimal processing conditions at all times. This not only improves efficiency but also enhances product uniformity and reduces the risk of human error.

In addition to efficiency, sustainability is also a key consideration in modern pet food production machinery. Manufacturers are increasingly implementing eco-friendly practices and incorporating energy-efficient technologies to minimize environmental impact. This includes the use of renewable energy sources, such as solar power, and the adoption of closed-loop systems to reduce water usage and waste generation.

Optimizing pet food production machinery is essential for meeting the growing demand for pet food while ensuring sustainability and product quality. By embracing innovative technologies and engineering solutions, manufacturers can achieve unprecedented levels of efficiency in pet food production, setting new standards for the industry.

Best Choice in Pet Food Equipment

When it comes to choosing the best equipment for pet food production, two companies stand out: LOYAL and Heat and Control. Let's compare their machines across various aspects in a simple table format:

|

Aspect |

LOYAL Company Machines |

Heat and Control Company Machines |

|

Technology |

Utilizes advanced extrusion technology |

Offers a range of equipment including fryers, ovens |

|

Efficiency |

High throughput with minimal downtime |

Efficient processing with precise control systems |

|

Customization |

Offers customizable solutions for unique needs |

Provides tailored solutions based on client demands |

|

Reliability |

Known for robust and reliable machinery |

Renowned for durable and dependable equipment |

|

Support |

Provides comprehensive technical support |

Offers extensive customer service and maintenance |

|

Innovation |

Constantly innovating to meet industry demands |

Embraces cutting-edge technologies for better results |

LOYAL Company Machines excel in extrusion technology, offering high throughput and customizable solutions to meet unique production requirements. On the other hand, Heat and Control Company Machines offer a diverse range of equipment, including fryers and ovens, with efficient processing and precise control systems. Both companies are known for their reliability and commitment to innovation, making them top choices in the pet food equipment industry.

Pioneering Pet Food Processing Solutions

Innovative solutions are vital for addressing the evolving needs of the pet food industry, and pioneering companies are at the forefront of developing advanced processing solutions. These solutions encompass a wide range of technologies and techniques aimed at improving efficiency, enhancing product quality, and meeting regulatory standards.

One area of innovation in pet food processing solutions is ingredient sourcing and preparation. Manufacturers are exploring alternative protein sources, such as insect protein and plant-based ingredients, to meet the growing demand for sustainable pet food options. Advanced processing techniques, such as micronization and enzymatic hydrolysis, are also being utilized to enhance ingredient digestibility and nutrient bioavailability.

Furthermore, advancements in extrusion technology are revolutionizing pet food production by allowing for the creation of customized textures and shapes. By precisely controlling parameters such as temperature, moisture, and pressure, manufacturers can tailor pet food formulations to meet specific dietary requirements and consumer preferences.

Packaging plays a crucial role in preserving the quality and freshness of pet food products. Pioneering companies are developing innovative packaging solutions, such as modified atmosphere packaging and barrier films, to extend shelf life and minimize food waste.

Unmatched Performance: Leading Pet Food Equipment Designs

When it comes to pet food equipment, performance is paramount. Leading manufacturers in the industry continually push the boundaries of design to ensure unmatched performance in their machinery. These designs are meticulously crafted to optimize efficiency, enhance productivity, and meet the diverse needs of pet food producers worldwide.

Innovative engineering lies at the heart of leading pet food equipment designs. Manufacturers leverage cutting-edge technologies to develop machinery that delivers superior performance across all stages of pet food processing. From ingredient handling and mixing to extrusion and packaging, every aspect of the production process is meticulously considered to achieve unparalleled results.

Leading pet food equipment designs prioritize versatility and adaptability. Manufacturers understand that pet food producers operate in a dynamic environment, requiring equipment that can seamlessly adjust to varying production demands and product specifications. As such, these designs often feature modular components and customizable settings, allowing for effortless optimization and flexibility in manufacturing operations.

In addition to performance, durability is a key aspect of leading pet food equipment designs. Manufacturers invest in high-quality materials and rigorous testing protocols to ensure their machinery withstands the rigors of continuous operation in demanding industrial settings. This commitment to durability not only minimizes downtime but also maximizes the longevity and reliability of the equipment, ultimately contributing to higher overall efficiency and cost-effectiveness.

Breakthroughs in Hygiene and Sanitation Standards for Pet Food Machinery

Maintaining impeccable hygiene and sanitation standards is essential in the pet food industry to ensure product safety and compliance with regulatory requirements. Breakthroughs in hygiene and sanitation standards for pet food machinery play a crucial role in safeguarding the quality and integrity of pet food products throughout the manufacturing process.

Leading manufacturers of pet food equipment are at the forefront of developing innovative solutions to enhance hygiene and sanitation practices. These breakthroughs encompass various aspects of equipment design, including materials selection, surface finishes, and sanitation protocols. For example, stainless steel, known for its corrosion resistance and ease of cleaning, is often used in the construction of pet food machinery to minimize the risk of contamination and facilitate thorough sanitation procedures.

Advancements in equipment design focus on reducing potential harborage areas for bacteria and other pathogens, thereby mitigating the risk of cross-contamination during production. Smooth, crevice-free surfaces, along with sanitary design principles such as sloped surfaces and easy-to-access components, enable more effective cleaning and disinfection processes, ensuring compliance with stringent food safety standards.

Automated sanitation systems have emerged as a game-changer in the pet food industry, streamlining and optimizing cleaning procedures while minimizing human intervention. These systems utilize innovative technologies such as CIP (Clean-in-Place) and COP (Clean-out-of-Place) to deliver thorough and efficient sanitation cycles, thereby enhancing overall hygiene and sanitation standards in pet food manufacturing facilities.

Custom Craftsmanship: Tailoring Pet Food Equipment to Unique Needs

In the highly diverse and dynamic landscape of the pet food industry, one size does not fit all. Recognizing the unique requirements and challenges faced by pet food producers, leading manufacturers offer custom craftsmanship services to tailor pet food equipment to individual needs.

Customization begins with a comprehensive assessment of the client's specific requirements, including production volume, product specifications, and facility layout. Based on this analysis, engineers work closely with clients to design bespoke solutions that address their unique challenges and objectives, ensuring optimal performance and efficiency.

Tailored pet food equipment solutions may encompass various modifications and enhancements, ranging from specialized tooling and accessories to fully customized production lines. For example, equipment can be adapted to accommodate specific ingredients, formulations, or packaging formats, allowing pet food producers to differentiate their products and meet the evolving demands of consumers.

By embracing custom craftsmanship, pet food producers can gain a competitive edge in the market by optimizing their production processes, enhancing product quality, and meeting the unique needs of their customers.

The Vanguard of Pet Food Equipment: Future Trends and Prospects

As the pet food industry continues to evolve and expand, the vanguard of pet food equipment is poised to drive innovation and shape the future of pet food manufacturing. Several key trends and prospects are emerging on the horizon, signaling exciting opportunities for manufacturers, producers, and consumers alike.

One of the most notable trends is the integration of advanced automation and digitalization technologies into pet food equipment. Robotics, artificial intelligence, and data analytics are revolutionizing the way pet food is produced, offering unprecedented levels of precision, efficiency, and quality control. Automated systems can optimize ingredient handling, streamline production processes, and ensure consistency in product quality, thereby enhancing overall operational efficiency and competitiveness.

Sustainability is becoming an increasingly prominent focus in pet food equipment design and manufacturing. With growing consumer awareness and demand for eco-friendly products, manufacturers are exploring innovative solutions to minimize resource consumption, reduce waste, and lower carbon footprints throughout the production lifecycle. This includes the use of recyclable materials, energy-efficient technologies, and waste reduction strategies to create more sustainable and environmentally responsible pet food equipment.

Moreover, the rise of personalized nutrition is driving demand for customizable pet food equipment solutions. Pet owners are seeking products tailored to their pets' specific dietary needs, preferences, and health requirements. In response, manufacturers are developing equipment that can accommodate a wide range of formulations, portion sizes, and packaging options, enabling pet food producers to offer personalized solutions that resonate with discerning consumers.

Overall, the future of pet food equipment is brimming with potential, fueled by innovation, sustainability, and consumer-centricity. By staying at the forefront of these trends and embracing new technologies, manufacturers can continue to lead the way in shaping the future of pet food manufacturing and meeting the evolving needs of pets and their owners.

FAQs: Frequently asked questions about Pet Food Equipment

1. What is pet food equipment?

Pet food equipment refers to machinery and tools specifically designed for the production, processing, and packaging of pet food products. This includes equipment for ingredient handling, mixing, extrusion, drying, coating, and packaging.

2. What types of machinery are included in pet food equipment?

Pet food equipment encompasses a wide range of machinery, including mixers, extruders, dryers, coating systems, packaging machines, and sanitation equipment. Each type of machinery plays a vital role in different stages of the pet food production process.

3. How important is hygiene and sanitation in pet food equipment?

Hygiene and sanitation are of utmost importance in pet food equipment to ensure the safety and quality of pet food products. Proper cleaning and sanitation protocols are essential to prevent contamination and maintain compliance with food safety regulations.

4. Can pet food equipment be customized to fit specific needs?

Yes, many manufacturers offer customization options for pet food equipment to meet the unique requirements of different producers. Customization may involve adjustments to equipment size, capacity, features, and capabilities to accommodate specific production processes and product specifications.

References

1. Petfoodindustry.com: https://www.petfoodindustry.com/

2. Petfoodprocessing.net: https://www.petfoodprocessing.net/

3. Foodengineeringmag.com: https://www.foodengineeringmag.com/

4. Foodprocessing.com: https://www.foodprocessing.com/

5. Foodtechconnect.com: https://foodtechconnect.com/