Fully Automated Lamb Defrosting in Microwave: Efficient and Energy-Saving Techniques

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:IMS,DanTech UK Ltd.

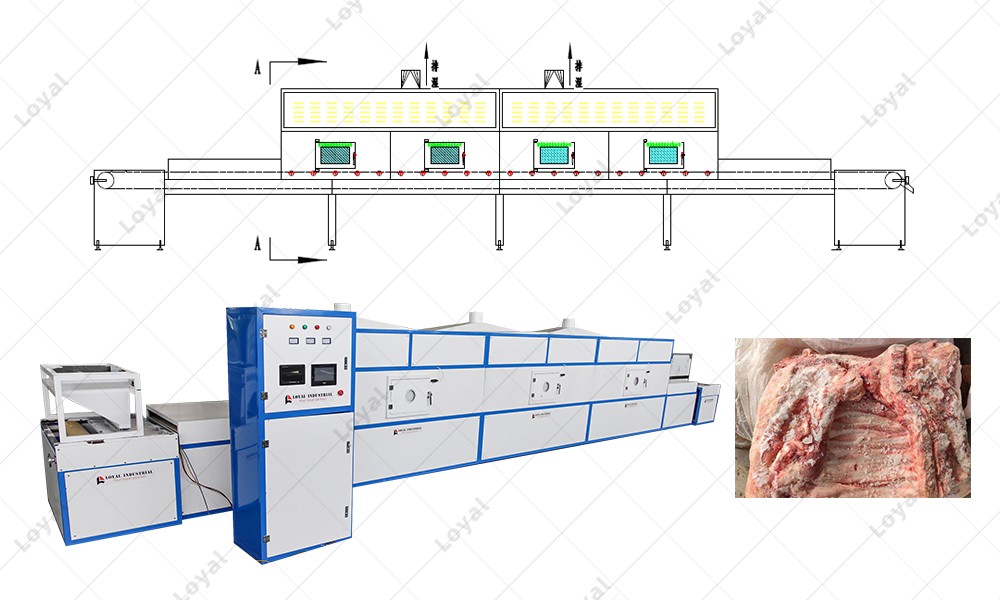

Introduction of defrost lamb in microwave

In the realm of culinary convenience, efficient lamb defrosting in the microwave has emerged as a pivotal component. This article delves into the significance of streamlined defrosting processes and introduces the concept of fully automated techniques geared towards energy-saving. As we navigate through this exploration, the aim is to unveil the transformative potential these techniques hold for the modern kitchen.

Understanding the defrost lamb in microwave Process

To comprehend the advancements in fully automated lamb defrosting, it's essential to grasp the science behind the process. Boldly innovating the traditional thawing methods, automated techniques optimize the lamb defrosting mechanism by precisely controlling energy levels and timing. The benefits extend beyond mere efficiency, encompassing substantial energy savings. Through a detailed examination, this section unveils the intricacies of how these techniques elevate the lamb defrosting experience.

Fully Automated Solutions for Lamb Defrosting

The latest technology in fully automated lamb defrosting systems marks a paradigm shift in kitchen efficiency. Boldly advancing the capabilities, these systems boast features such as intuitive interfaces and sensor-driven precision, setting them apart from traditional methods. This section offers an insightful overview, emphasizing the transformative nature of fully automated solutions and drawing comparisons with conventional lamb defrosting techniques.

Techniques for Efficient Lamb Defrosting

Maximizing efficiency in lamb defrosting involves strategic utilization of fully automated methods. Bold strategies aimed at minimizing time and energy consumption take center stage. Real-life examples underscore the effectiveness of these techniques, providing readers with tangible evidence of the benefits associated with adopting fully automated approaches.

Energy-Saving Measures in defrost lamb in microwave

Fully automated solutions for lamb defrosting not only prioritize efficiency but also contribute significantly to energy conservation. Boldly paving the way for eco-friendly kitchen practices, this section delves into the mechanisms by which these solutions minimize energy consumption. A meticulous comparison between automated and manual lamb defrosting methods sheds light on the environmental benefits, encouraging readers to adopt practices that align with sustainability.

Overcoming Common Challenges of defrost lamb in microwave

Efficiency and convenience can sometimes encounter challenges. This section addresses potential issues and provides troubleshooting tips tailored for users of fully automated systems. By offering practical solutions, this article ensures that readers can navigate through common challenges, guaranteeing a smooth and trouble-free experience with advanced lamb defrosting techniques.

Future Trends and Innovations in defrost lamb in microwave

As technology continues its relentless march forward, the future of lamb defrosting holds exciting possibilities. Boldly venturing into uncharted territories, this section explores ongoing research and potential advancements. From intelligent sensors to cutting-edge materials, readers gain insights into the innovations that may shape the future of microwave lamb defrosting. The article provides a forward-looking perspective, inviting readers to stay informed about emerging trends in kitchen technology.

Conclusion

In conclusion, the journey through fully automated lamb defrosting in the microwave unveils a realm of possibilities for enhanced kitchen experiences. The benefits, ranging from efficiency and energy savings to eco-conscious practices, are encapsulated in the adoption of these advanced techniques. Encouraging readers to explore and embrace the transformative power of fully automated solutions, the conclusion serves as a rallying call for a more efficient and sustainable kitchen future. As technology continues to evolve, so does the potential for elevating our culinary endeavors. Embrace innovation, optimize efficiency, and redefine your kitchen experience with fully automated lamb defrosting.

FAQs: Common Questions About Defrosting Lamb in Microwave

Q1: How does fully automated lamb defrosting differ from traditional methods?

A: Fully automated lamb defrosting utilizes advanced technology to optimize the thawing process, offering precise control and efficiency. This section elaborates on the distinctions between fully automated techniques and traditional methods.

Q2: Are there any specific lamb cuts better suited for microwave defrosting?

A: Microwave defrosting is versatile and can be applied to various lamb cuts. The article delves into the compatibility of different cuts with fully automated systems, providing guidance for users.

Q3: Is there a risk of uneven defrosting with fully automated techniques?

A: The advanced features of fully automated systems minimize the risk of uneven defrosting. This section addresses concerns related to even defrosting and explains how these techniques overcome such challenges.

Q4: How does energy consumption compare between automated and manual lamb defrosting?

A: Energy-saving measures are a key aspect of fully automated lamb defrosting. The article discusses the energy consumption differences between automated and manual methods, emphasizing the eco-friendly aspects of fully automated techniques.