High-Efficiency Solutions: The Automated Approach to Meat Defrosting

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Cellencor ,DanTech UK Ltd.

Meat defrosting is a pivotal stage in food processing, influencing the quality and efficiency of the final product. Traditional methods have posed challenges, necessitating a paradigm shift towards more efficient solutions.

Traditional thawing methods present limitations in terms of time, precision, and scalability. This section explores the shortcomings of manual defrosting and sets the stage for the introduction of automated solutions.

The advent of meat defrosting machines marks a revolutionary approach to address the challenges of traditional methods. This section introduces the concept of automated defrosting, emphasizing its high-efficiency solutions in transforming meat processing.

Advantages of Automated Meat Defrosting

Meat defrosting machines leverage rapid thawing technologies, ensuring swift and precise thawing. This subsection explores the technological innovations that contribute to the speed of the process, meeting the demands of fast-paced food industries.

Precision control mechanisms in automated systems guarantee a consistent and controlled thawing process. This section highlights the importance of precision in preserving the integrity of the meat and meeting quality standards.

Automated defrosting plays a crucial role in preserving the quality of meat. By minimizing the risk of over-thawing and ensuring controlled conditions, these machines contribute to maintaining the texture, flavor, and nutritional value of the meat.

This subsection explores how meat defrosting machines enhance operational efficiency, allowing food processing facilities to handle larger volumes of meat with increased throughput. The automation of the thawing process streamlines workflows, reducing operational bottlenecks.

Types of Automated Meat Defrosting Machines

Air-based systems represent a category of meat defrosting machines known for their efficiency. This section delves into the principles behind air-based defrosting, emphasizing how controlled airflow accelerates the thawing process while maintaining the meat's quality.

Water immersion techniques, automated for efficiency, provide an alternative approach to defrosting. This subsection explores how automated water immersion systems optimize the thawing process, ensuring uniform results and contributing to the preservation of meat quality.

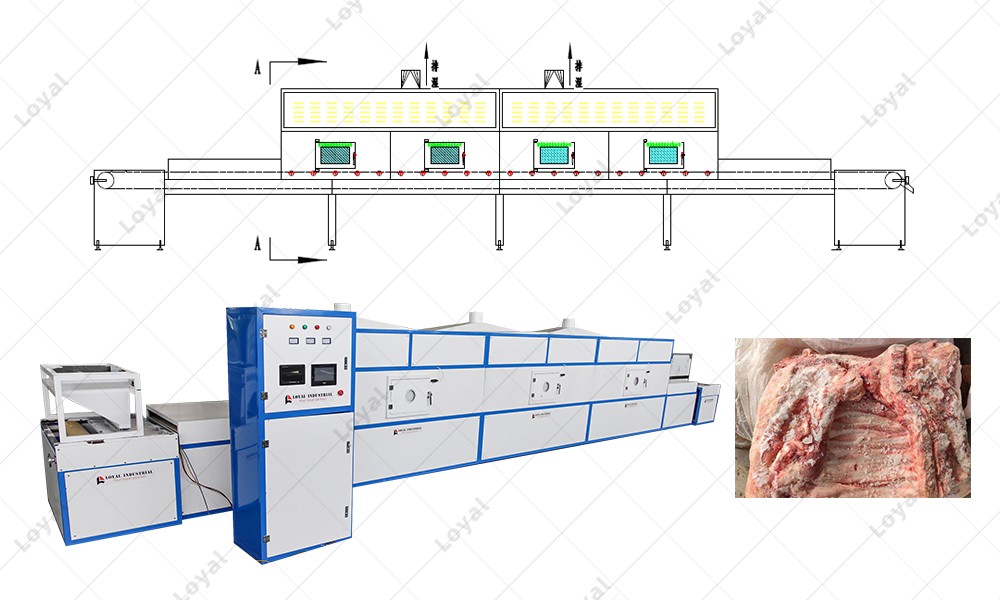

Microwave defrosting, an innovative approach in automated systems, is explored in this section. It delves into the advancements in microwave technology integrated into meat defrosting machines, highlighting the speed and precision offered by this method.

Implementing Automated Meat Defrosting in Food Industries

Real-world success stories of large-scale processing facilities adopting automated meat defrosting are examined in this section. These case studies demonstrate the tangible benefits, including increased efficiency, improved product quality, and enhanced overall productivity.

This subsection explores the economic benefits derived from implementing meat defrosting machines. Improved operational efficiency, reduced labor costs, and minimized waste contribute to improved profit margins for businesses embracing automated solutions.

Voices of industry experts provide authoritative insights into the transformative impact of automated meat defrosting. This section incorporates testimonials and quotes, emphasizing the credibility and endorsement of these machines by professionals in the field.

Addressing Concerns and Challenges

Addressing concerns related to food safety, this section highlights how automated meat defrosting machines adhere to stringent standards, ensuring that the final product meets regulatory requirements and maintains high-quality standards.

Potential challenges associated with the initial investment in automated defrosting technology are addressed in this section. Strategies for overcoming these barriers are explored, emphasizing the long-term benefits and return on investment.

The environmental impact of automated defrosting is examined, emphasizing the sustainability aspects of these machines. From energy-efficient technologies to reduced water consumption, this section discusses how meat defrosting machines align with eco-friendly practices.

Future Trends and Innovations

The integration of Artificial Intelligence (AI) into meat defrosting machines is explored in this section. AI-driven algorithms promise enhanced precision and adaptability, optimizing thawing parameters based on real-time data.

An analysis of market trends and projections is presented, highlighting the anticipated growth of the meat defrosting machine market. The global adoption of automated solutions is expected to reshape the landscape of the entire industry.

This section explores potential advancements in Machine Learning (ML) algorithms, offering insights into how continuous innovation can further enhance the precision, speed, and adaptability of meat defrosting machines.

Common Queries about Meat Defrosting Machines

This section aims to address common queries and concerns that readers may have about meat defrosting machines, providing informative responses to enhance understanding.

How do automated meat defrosting machines work?

Automated meat defrosting machines work by employing advanced technologies such as controlled airflow, water immersion, or microwave technology. These methods ensure rapid and precise thawing, preserving the quality of the meat.

Are there specific types of meat better suited for automated defrosting?

Automated defrosting is versatile and suitable for various types of meat, including beef, poultry, and seafood. The technology can be adjusted to accommodate different textures and sizes, ensuring consistent results across diverse meat products.

How do these machines contribute to environmental sustainability?

Meat defrosting machines contribute to sustainability through energy-efficient technologies and reduced resource consumption. The automated process minimizes waste and optimizes energy usage, aligning with eco-friendly practices.

What are the economic benefits for businesses implementing automated meat defrosting?

Businesses benefit economically from automated meat defrosting through improved operational efficiency, reduced labor costs, and minimized waste. These factors collectively lead to enhanced profit margins and a competitive edge in the market.

How can businesses overcome the initial investment challenges?

Overcoming initial investment challenges involves considering the long-term benefits of automated defrosting, including increased efficiency and improved product quality. Additionally, exploring financing options and assessing the return on investment can help businesses make informed decisions.

Are there any food safety concerns associated with automated meat defrosting?

Automated meat defrosting machines are designed to adhere to stringent food safety standards. The controlled and monitored thawing process minimizes the risk of contamination, ensuring that the final product meets regulatory requirements.

What is the role of Artificial Intelligence in meat defrosting machines?

Artificial Intelligence enhances meat defrosting machines by optimizing thawing parameters based on real-time data. AI-driven algorithms contribute to precision, adaptability, and efficiency, further advancing the capabilities of these machines.

Conclusion

In conclusion, the comprehensive exploration of high-efficiency solutions through automated meat defrosting machines underscores their transformative impact on the food processing industry. From addressing traditional challenges to fostering economic benefits and sustainability, these machines pave the way for a more efficient and innovative future.

The encouraging adoption of automated solutions not only enhances operational processes but also contributes to the broader industry transformation. As businesses recognize the advantages of automated meat defrosting, they play a crucial role in shaping a more sustainable and technologically advanced landscape for the entire food processing sector.