Innovative Meat Defrosting: Full Automation for Enhanced Efficiency

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:SAIREM,Thermex-Thermatron Systems.

The meat processing industry faces significant challenges in the defrosting stage, impacting efficiency and operational streamlining. This article explores the theme of "Innovative Meat Defrosting Full Automation for Enhanced Efficiency," emphasizing the importance of adopting fully automated defrosting methods to overcome challenges and optimize meat processing operations.

Current Issues in Meat Defrosting

Traditional meat defrosting methods encounter challenges such as prolonged processing times, uneven thawing, and potential compromises in meat quality. These limitations prompt a growing demand for innovative solutions within the meat processing industry. Stakeholders are actively seeking methods to overcome inefficiencies and elevate the defrosting process to meet the evolving standards of efficiency and quality.

The introduction of full automation concepts marks a significant shift in addressing these challenges. As the industry acknowledges the need for enhanced efficiency, the integration of automated technologies into the meat defrosting process emerges as a transformative solution. This section will further delve into the specific issues faced by traditional methods and highlight how the introduction of full automation has the potential to revolutionize and optimize meat defrosting practices.

Unveiling Automatic Defrosting Technology

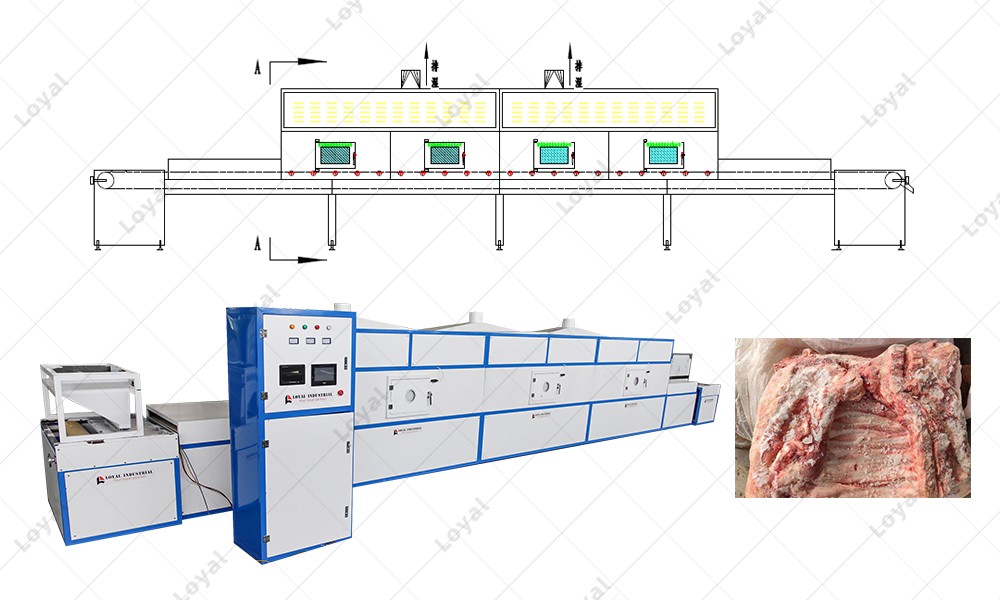

In this comprehensive exploration, we delve into the intricate principles and mechanisms that underlie innovative meat defrosting machines. These cuttingedge technologies operate seamlessly, revolutionizing the traditional approach to defrosting. The comparative analysis conducted in this section aims to illuminate the distinct advantages offered by full automation in contrast to conventional defrosting methods.

The innovative meat defrosting machines, through their automated features, demonstrate a significant leap forward in efficiency. The precision, speed, and overall effectiveness of these technologies surpass the capabilities of traditional methods. This section will provide a detailed examination of how full automation aligns with the industry's objectives, emphasizing the pursuit of elevated efficiency and streamlined operations in meat processing. Through this unveiling of automatic defrosting technology, the transformative impact on the meat processing landscape becomes increasingly evident.

Technological Features of Automated Meat Defrosting Machine

This segment provides a comprehensive overview of the features defining a fully automated meat defrosting machine. Emphasizing precision, speed, and overall efficiency in the defrosting process, it illustrates how automation contributes to optimizing meat processing while ensuring highquality thawing.

Realworld Impact and Success Stories

The article transitions to practical applications, showcasing how fully automated meat defrosting machines have made a substantial impact in production. Testimonials and success stories from businesses highlight quantifiable improvements in efficiency, processing speed, and overall meat quality, attributing these achievements to the adoption of full automation in the defrosting process. These realworld examples serve as compelling evidence of the positive outcomes that fully automated meat

Advantages for the Meat Industry

Delving deeper into the advantages, this section explores how fully automated defrosting preserves meat quality, texture, and nutritional value. The broader impact includes increased production capacity, reduced processing time, and an overall enhancement in the quality of meat products, marking a significant leap forward for the meat processing industry. The advantages outlined in this section underscore the transformative nature of fully automated defrosting, presenting a compelling case for its widespread adoption across the meat processing sector.

Overcoming Challenges in Implementation

Identifying challenges associated with implementing fully automated meat defrosting machines, this section provides effective solutions to overcome potential obstacles. Strategies for seamless integration into meat processing facilities are explored, ensuring that the adoption of advanced defrosting methods is smooth and efficient. Addressing these challenges is crucial for maximizing the benefits of automation in meat defrosting, as a wellplanned and executed implementation can lead to enhanced operational efficiency and overall success in the meat processing industry.

Regulatory Compliance and Quality Standards

Recognizing the importance of meeting regulatory requirements in the meat processing industry, the article delves into how fully automated meat defrosting ensures compliance with stringent quality standards. Collaboration with regulatory authorities is emphasized, highlighting the commitment to establishing and maintaining industry best practices for the benefit of both producers and consumers. Maintaining regulatory compliance is a key aspect of the adoption of innovative defrosting technologies.

Future Trends and Innovations

Exploring anticipated trends in the continued application of fully automated meat defrosting, this section discusses innovations on the horizon that could further enhance efficiency and sustainability in meat processing. The role of technology takes center stage in shaping the future of the meat processing industry, offering insights into the evolving landscape and potential advancements.

Conclusion

Summarizing key points regarding the impact of fully automated meat defrosting on optimizing production efficiency, the conclusion encourages meat processors to embrace innovative technologies for enhanced quality, efficiency, and compliance with industry standards. It provides a forwardlooking perspective on the ongoing evolution of defrosting practices in the meat processing industry, emphasizing the continuous pursuit of efficiency and quality improvement.

Common Questions About Meat Defrosting Machine

1. How does a meat defrosting machine work?

Answer: Meat defrosting machines use advanced technologies such as microwaves or forced air to thaw frozen meat efficiently. The process is carefully controlled to ensure uniform thawing without compromising meat quality.

2. What makes fully automated meat defrosting different from traditional methods?

Answer: Full automation in meat defrosting eliminates the need for manual intervention. It ensures precise control over the thawing process, resulting in higher efficiency, reduced processing time, and enhanced overall meat quality.

3. Are there variations in defrosting methods based on the type of meat?

Answer: Yes, different meats may require specific defrosting methods based on their composition and structure. A versatile meat defrosting machine can be adjusted to accommodate various types of meat.

4. Can fully automated defrosting preserve the nutritional value of meat?

Answer: Absolutely. Fully automated defrosting minimizes the time meat spends in the thawing process, helping to retain essential nutrients and ensuring the final product maintains its nutritional value.

5. How does regulatory compliance factor into meat defrosting processes?

Answer: Regulatory compliance is crucial in meat processing. Fully automated meat defrosting machines are designed to meet industry standards, and collaboration with regulatory authorities ensures adherence to quality and safety regulations.

6. What challenges might businesses face when implementing automated meat defrosting?

Answer: Implementing automated meat defrosting machines may pose challenges such as initial setup costs and integration into existing processing facilities. However, strategic planning and consultation can help overcome these challenges seamlessly.

nswer: Technology will continue to play a pivotal role in advancing meat defrosting processes. Innovations may focus on further efficiency improvements, energy conservation, and sustainable practices.

This section aims to provide detailed answers to common questions, offering valuable insights into the functionality and benefits of innovative meat defrosting machines.