How To Realize The Simulation Of The Vegetarian Meat Food That Is Behind The Crushing And Extrusion?

Recently, the French government introduced a new regulation. It is stipulated that French food production companies cannot use the name of meat on vegan food. That is, names such as vegetarian ham are not allowed. Ham is ham. If it is vegetarian, the name ham cannot be added.

Nowadays, vegetarian meat has entered the daily life of the public. Many restaurants have "meat dishes" such as vegetarian abalone and vegetarian chicken. There are also many vegetarian meals such as pixel sausages, vegetarian burgers, and vegetarian bacon in Western food. In the snack food industry, vegetarian meat also occupies a place. Now Shandong Loyal talks about the development status of vegetarian meat and the technical equipment involved in its production, so that everyone has a better understanding of vegetarian meat food.

Vegetarian meat made by soya extruder machine refers to the vegetarian food with the flavor and texture similar to real meat. Generally, plant protein is used as the main raw material and is made through modern processing techniques such as extrusion, steaming, and molding. At present, vegetarian meat products include vegetarian meat blocks, vegetarian meatballs, vegetarian ham sausages, etc. With the rapid development of technology, many innovative vegetarian meat made by soya chunks manufacturing machine products emerge in endlessly.

A professor of biochemistry at a university in the United States and his team spent tens of millions of dollars in 5 years to develop a vegetarian meat pie that is almost the same as real meat. This vegetarian meatloaf is composed of potato, wheat protein, xanthan gum and other substances. The unique production process is that it decomposes protein from plants. It also extracts heme to produce chemical reactions with sugars, vegetable fats and other elements. So as to realize the fragrance, texture and color of real meat. It can be seen that the reward for spending 5 years is the discovery of processing technology that can produce simulated vegetarian meat. It is also the extraction and decomposition processes to achieve the perfect simulation effect of vegetarian meat. Therefore, technical equipment is vital to the innovation and production of this new category of vegetarian meat.

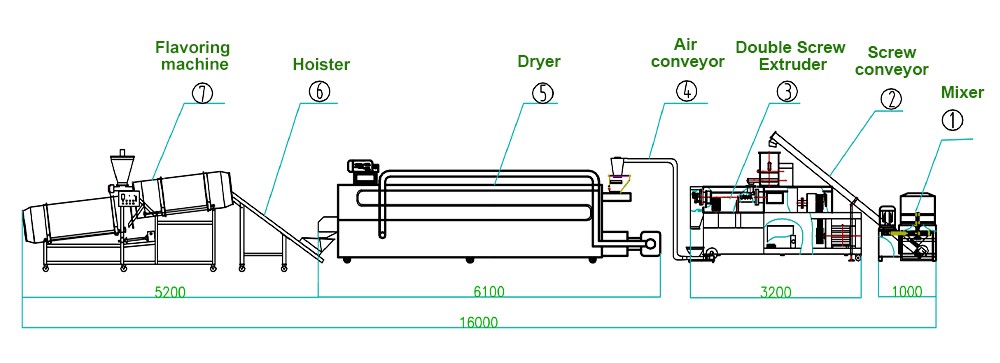

The production of vegetarian meat usually includes steps such as crushing, extrusion, preparation, and drying. Among the existing vegetarian meat products, protein vegetarian meat is our most common category. The raw material for the production of protein meat is soy protein. The raw material is first ground into a powder by a grinder, which provides a basis for the subsequent preparation process. Modulation is to mix the previously crushed soy flour with salt, water and other materials, and the manufacturer will modulate it into different flavors according to its own formula.

The preparation process requires uniform mixing of materials. So there are certain requirements for the performance of the mixer's uniformity. As mentioned above, most of the mixed materials of protein meat are powdery substances. There are also professional high-quality mixers for the mixing of powdery materials on the market. For example, the powder material mixing machine manufactured by safe foods uses a unique spiral tooth arrangement to make the mixing of materials more uniform and full. It also has the functions of automatic feeding, automatic discharging and forward and reverse rotation. And it greatly improves operation efficiency.

Extrusion and puffing are carried out after preparation and mixing. This step is the key to whether the finished product has real meat structure and taste. Put the mixed materials into a twin screw extruder to pressurize and heat to shape the materials. In the process, if you want to achieve a high-quality molding appearance and a delicate and firm taste, you have to keep warm.