How To Make Rice Straws By Using The Rice Straw Production Line?

The rice straw is made of rice and cassava (cassava is the raw material for making pearls in bubble milk tea, which can make the straw strong and tough, and the surface is smoother), which is made by a puffing extrusion process. Its appearance is no different from ordinary plastic straws. The surface of rice straws is smooth, strong and tough. Compared with ordinary plastic straws, rice straws can be eaten directly, and the taste is crispy and crispy, and the taste is like people's common fried rice. The raw materials can also be adjusted to make straws of different colors.

The rice straw made by the puffing extrusion process can be soaked in hot drinks for 2 to 3 hours, while in cold drinks it can last longer, up to 5 to 10 hours. In addition, the rice straw made by full automatic rice straws production line is completely degradable, which is more eco-friendly, and can be used as a substitute for plastic straws. The rice straws will not pollute the environment like plastic straws, and it also meets the requirements of multinational regulations.

The rice straw made by the puffing extrusion process can be soaked in hot drinks for 2 to 3 hours, while in cold drinks it can last longer, up to 5 to 10 hours. In addition, the rice straw made by full automatic rice straws production line is completely degradable, which is more eco-friendly, and can be used as a substitute for plastic straws. The rice straws will not pollute the environment like plastic straws, and it also meets the requirements of multinational regulations.

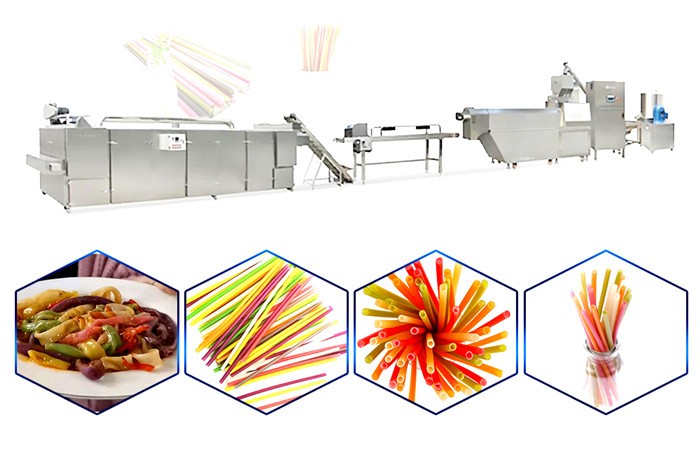

The rice straw making machine equipment of Shandong Loyal Industrial Co., Ltd. is made into blanks of various sizes through a single screw extruder, and then dried to form a straw with a smooth surface and a realistic shape. Our unit screw combination technology and production process control enable a wider selection of raw materials for rice straws, higher product quality, and more variety. A single-screw extruder can complete the processes of mixing, kneading, cooking, and extrusion.

The rice straw making machine equipment of Shandong Loyal Industrial Co., Ltd. is made into blanks of various sizes through a single screw extruder, and then dried to form a straw with a smooth surface and a realistic shape. Our unit screw combination technology and production process control enable a wider selection of raw materials for rice straws, higher product quality, and more variety. A single-screw extruder can complete the processes of mixing, kneading, cooking, and extrusion.

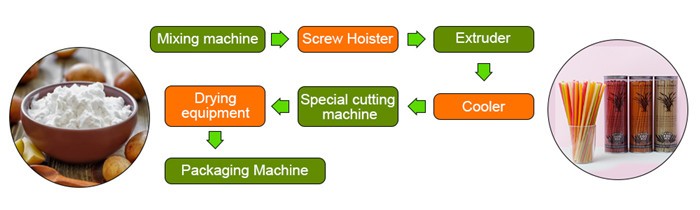

1. Production process of rice straws processing line:

Raw material configuration-raw material mixing-extrusion molding-hot air drying-cutting

2. Equipment configuration of automatic rice straw production line:

Powder mixing machine → screw hoister → extruder → cooler →cutting machine → elevator → multi-layer oven → cooling conveyor → packaging machine

3. Process composition of commercial rice straw making machine:

1. Flour mixing machine: separate rice noodles or mix some additives, add a certain amount of water and mix well.

2. Feeding machine: The motor is used for power screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Extruder: There is a special control cabinet, which can squeeze out rice grains under high pressure environment, adjust the process and change the mold to produce rice grains of different shapes.

4. Cutting machine: single cut according to size.

5. Hoist: The product is transported to the oven, and the height of the hoist is determined according to the oven.

6. Multi-layer oven: most ovens are electric ovens. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh bag. The baking time can be adjusted according to the speed, minus the particle moisture, and increase the shelf life;

7. Cooling conveyor: The dried particles contain a certain temperature, and the packaging quality is guaranteed by cooling to room temperature.