How Much Do You Know About The Rice Straw Production Line?

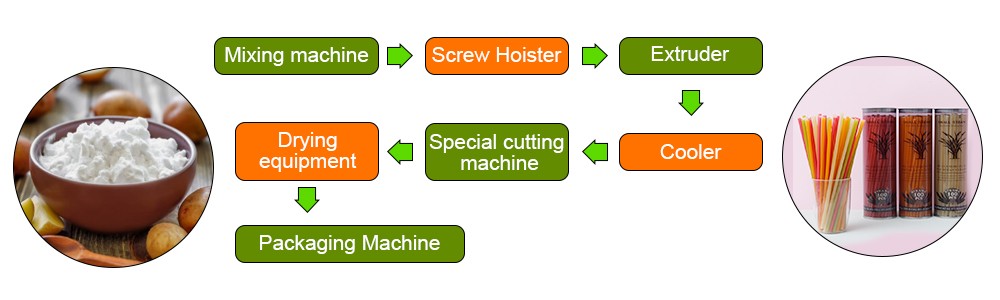

Introduction: The rice straw is made of rice flour, corn starch and other raw materials, which are extruded and cooled by an extruder to form and cut. The special cutting machine can be used to cut different lengths, different diameters, different thicknesses, etc., and after cooling, forming and drying use. This kind of straw has the characteristics of environmental protection, no additives, edible, etc., suitable for the crowd: the elderly, children, infants, high-end catering market.

Introduction to straws: In appearance, rice straws are similar to ordinary plastic straws, and the taste of the drink will not be affected. The straws can be eaten directly, and the taste is harder, which is similar to rice crisps. The rice straw can be soaked in hot drinks for two to three hours, and it lasts longer in cold drinks. The production process of rice straws is not complicated. The company has already adopted automation and large-scale production. The current monthly output has increased to about 300 million, and it plans to supply hundreds of cafes and some hotels in South Korea.

Korean rice straw: In addition to 70% rice, the straw contains 30% cassava, which is the material used to make pearls in bubble tea. This is to make the straw strong and flexible, and the surface smoother.

The rice straw made by the puffing extrusion process can be soaked in hot drinks for 2 to 3 hours, while in cold drinks it can last longer, up to 5 to 10 hours. And the rice straw can be completely degraded, which is more eco-friendly, and can be used as a substitute for plastic straws

Rice straw processing machine, rice straw complete equipment, rice straw complete production line, rice straw equipment supplier, the rice straw production process abandons the traditional production technology and production methods, and creates a brand-new production method, with rice flour and tapioca flour As the main raw material, after extensive verification, it will not affect the ingestion of fluid milk products, that is, it will not melt, and can be eaten, will not pollute, and can achieve the purpose of environmental protection. The host adopts frequency conversion speed regulation to ensure the stability of the production process. The products are of various colors, varieties, beautiful appearance, natural lifelike, delicate texture, and extensive use of raw materials.

Edible straws have become a hot spot for research and development. Edible straws that replace plastic straws must have the following characteristics: they are not easy to soak, not easy to taste, and low in price. According to this market characteristic, Shandong Loyal Industrial Co., Ltd. has researched and developed edible rice straw production equipment. The edible straw production line mainly uses rice, tapioca rice noodles, etc. as raw materials and uses a unique extrusion molding process to produce popular secondary puffed foods of various shapes on the market. The production line has reasonable design, high degree of automation, precise control of extrusion parameters, and the main engine is equipped with high and low pressure screws, which increases the use of raw materials, reduces costs, and improves product quality. This machine adopts internationally advanced twin-screw extrusion technology, combined with the company’s years of experience in expanding technology, and is a new type of expanded food equipment designed and manufactured to meet the needs of food and related industries. The series twin screw machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system.

At present, the monthly output of “rice straws” has reached 300 million. Compared with traditional packaging, edible packaging such as “rice straws” truly achieves “zero burden on the ecological environment”. When the food is eaten, its service life will also end. The relationship between life and death. Some Chinese businesses have begun to replace straws made of degradable materials.