How Does The Automatic Pillow Packaging Machine Work?

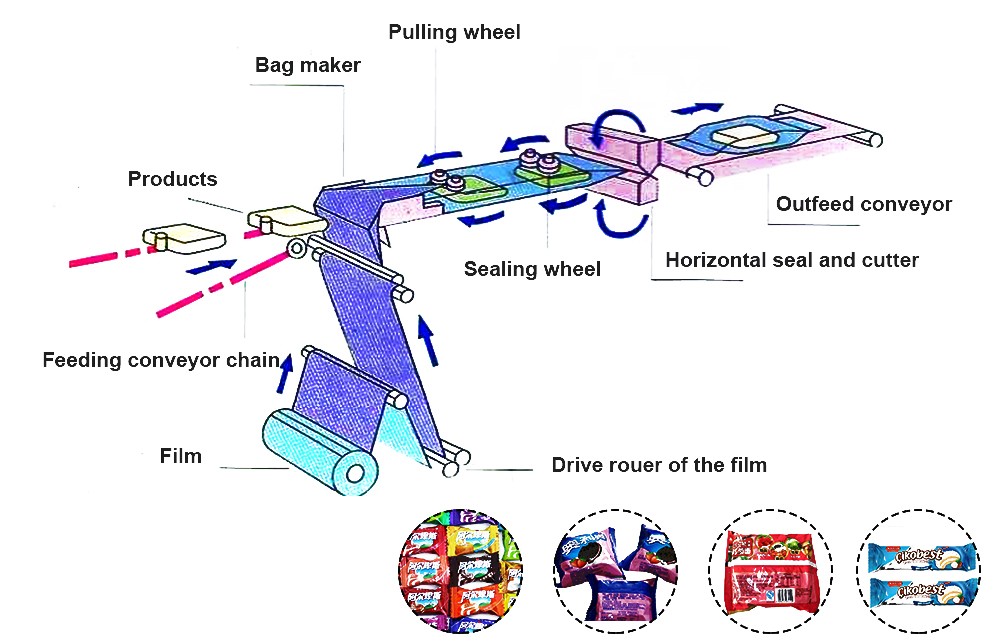

The automatic pillow packaging machine is currently the latest automatic continuous shrink packaging equipment.

|

1 |

Using quartz far-infrared tube heating, saving electricity and high efficiency; |

|

2 |

The shrinkage temperature and motor transmission speed are stable and adjustable, and the adjustment range is wide; |

|

3 |

The original roller rotation device can work continuously. |

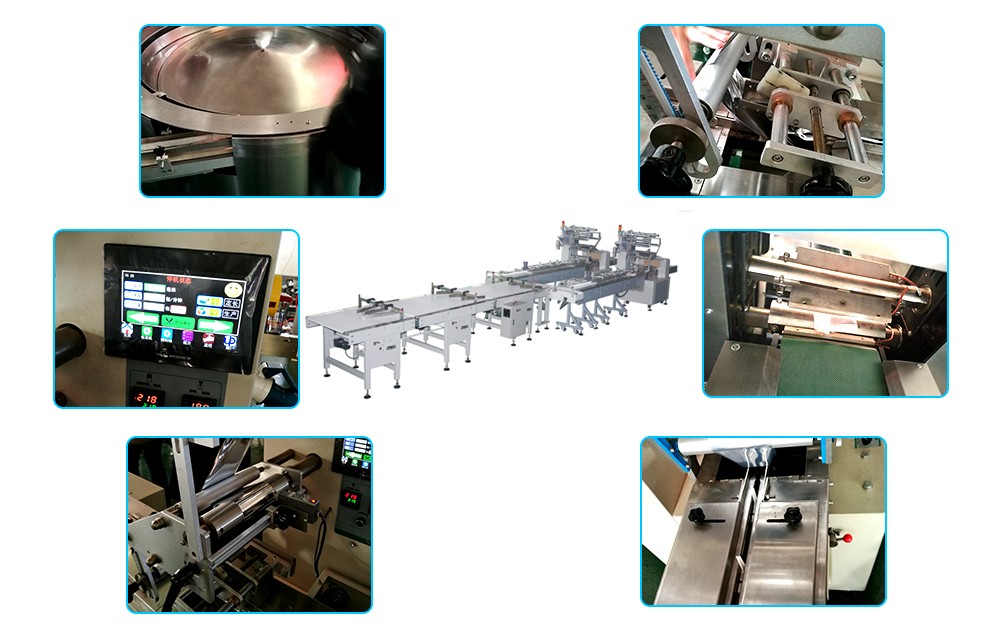

How much do you know about the industrial pillow packaging machine? Next, Shandong Loyal will introduce the structure and characteristics of the high-speed pillow packaging machine:

1) Double inverter control, the bag length is set and cut immediately, no need to adjust the idling, one step is in place, saving time and film.

2) Text-based man-machine interface, convenient and quick parameter setting.

3) Fault self-diagnosis function, fault display is clear at a glance.

4) High-sensitivity photoelectric eye color mark tracking makes the sealing and cutting position more accurate.

5) Independent PID control of temperature, which is better suitable for coating of various materials.

6) Positioned stop function, no sticking to the knife, no waste of film.

7) The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8) All control is realized by software, which is convenient for function adjustment and technical upgrade, and never lags behind.