Features And Maintenance Of Twin Screw Extruder Machine

Features Of Double Screw Extruder:

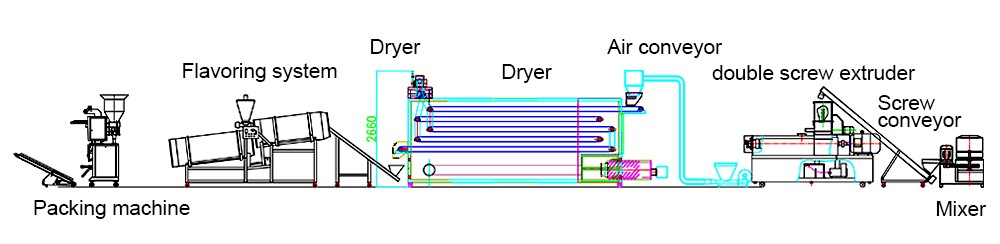

1. The series of automatic twin screw extruders machine are mainly composed of feeding system, extrusion system, rotary cutting system, heating system, lubrication system and control system.

2. The industrial extruder feeding system, main drive system and rotary cutting system all adopt frequency conversion speed regulation. It has strong power, stable operation and energy saving.

3. Automatic lubrication and forced cooling to ensure the safe operation of the extruder and prolong life.

4. For different raw materials, different single and twin screw feeding systems are designed to ensure uniform, stable and reliable feeding.

5. The screw is made of alloy material and processed by special technology. It has high strength, wear resistance and long service life.

6. According to different product requirements, full automatic double screw extrusion systems with different structures and length-diameter ratios are designed to meet process requirements.

Extrusion machine maintenance:

Circuit: Pay attention to the cleaning of the circuit board, regularly clean the dust of the strong and weak electric boxes, keep the electric boxes dry and prevent moisture.

Oil circuit: Check whether there is oil leakage in various parts of the oil circuit, and deal with it in time. Prevent the piston rod from scratching and oil deterioration.

Machinery: Check whether the transmission part of the machine is worn or not, check whether each grease nipple is blocked, and inject grease.

Other precautions: It is recommended to replace the hydraulic oil once a year and clean the oil sludge in the oil tank. The water cooler should be cleaned in time to prevent the oil temperature from rising and accelerating the aging of the oil. Of course, safety is no small matter. The circuit safety door switch, the oil circuit pressure relief valve, and the mechanical safety block , double screw extruder machine warning lights must be checked for normal operation during maintenance.