Edible Rice Straw Production Line

With the development of science and technology and the improvement of people's living standards, society is paying more and more attention to the issue of environmental pollution. However, this is a big project that needs to start from oneself and from every small thing. Since the promulgation of the plastic restriction order, certain results have been achieved in my country, and plastic pollution has attracted more and more public attention.

In fast food restaurants and drink shops, plastic straws are the most commonly used by shopkeepers. This is also a kind of plastic pollution. In order to solve this situation, many people in society have begun to turn their minds and create new things to replace plastic straws. The edible straw has become a hot spot for research and development.

For example, the edible straws designed and produced in the United States use seaweed as raw materials, add edible spices and pigments, and have various flavors. They can be soaked in a drink for 24 hours without deformation. There are also pasta straws and water spinach straws.

For example, the edible straws designed and produced in the United States use seaweed as raw materials, add edible spices and pigments, and have various flavors. They can be soaked in a drink for 24 hours without deformation. There are also pasta straws and water spinach straws.

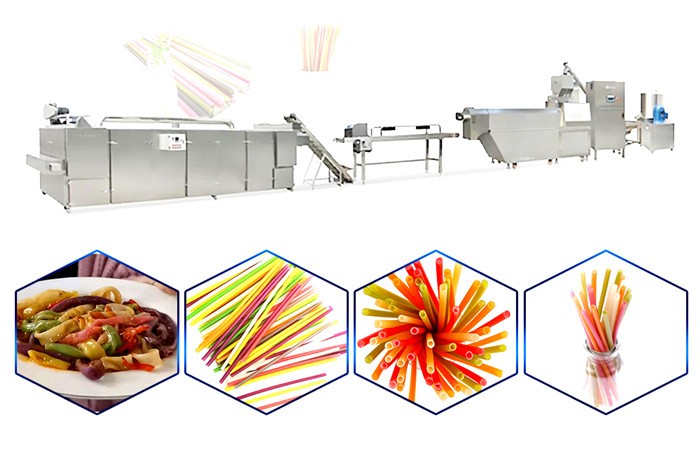

In response to market demand, Shandong Loyal Industrial Co., Ltd. has also developed an edible rice straw production line, which is very popular.

1. Introduction of food grade automatic rice straw production line

The rice straw is made of rice and cassava (cassava is the raw material for making pearls in bubble milk tea, which can make the straw strong and tough, and the surface is smoother), which is made by a puffing extrusion process. Its appearance is no different from ordinary plastic straws. Compared with ordinary plastic straws, rice straws can be eaten directly, and the taste is crispy and crispy, and the taste is like people's common fried rice. The raw materials can also be adjusted to make straws of different colors.

The rice straw is made of rice and cassava (cassava is the raw material for making pearls in bubble milk tea, which can make the straw strong and tough, and the surface is smoother), which is made by a puffing extrusion process. Its appearance is no different from ordinary plastic straws. Compared with ordinary plastic straws, rice straws can be eaten directly, and the taste is crispy and crispy, and the taste is like people's common fried rice. The raw materials can also be adjusted to make straws of different colors.

The rice straw made by the puffing extrusion process can be soaked in hot drinks for 2 to 3 hours, while in cold drinks it can last longer, up to 5 to 10 hours. And the rice straw can be completely degraded, which is more friendly to the ecological environment, and can be used as a substitute for plastic straws.

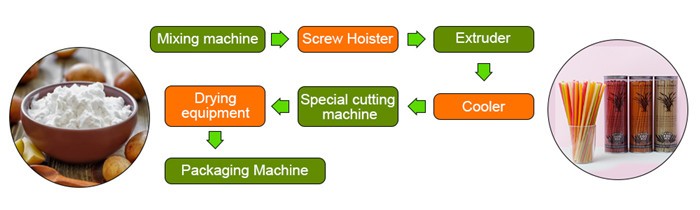

2. Equipment process of industrial rice straw production line

Raw material mixing → Extrusion molding (cutting molding → cooling → cutting → drying → packaging Edible

3. Features of rice straws which produced by commercial edible rice straw processing line:

a. It can be completely degraded;

b. It can be used for green composting;

c. No plastic ingredients;

d. It is suitable for cold and hot drinks;

e. It can be eaten directly, etc.;

4. Product raw materials:

Mainly broken rice, rice flour, corn starch, tapioca starch, potato starch, potato whole wheat flour, etc. as raw materials, are extruded by a twin-screw extruder into blanks of various specifications, and then dried to form a smooth surface and a realistic shape straw; a twin-screw extruder can complete the process of mixing, kneading, curing, and extrusion in the full automatic edible rice straw production line.

5. Sample display

Compared with ordinary straws, the products produced by Shandong Loyal Industrial Co.,Ltd. food-grade rice straw making machine have the characteristics of unique technology, reasonable configuration, high degree of automation, stable performance, environmental protection and pollution-free, etc., and can be used with meals after use. Also it can throw away or use it directly afterwards.

Compared with ordinary straws, the products produced by Shandong Loyal Industrial Co.,Ltd. food-grade rice straw making machine have the characteristics of unique technology, reasonable configuration, high degree of automation, stable performance, environmental protection and pollution-free, etc., and can be used with meals after use. Also it can throw away or use it directly afterwards.