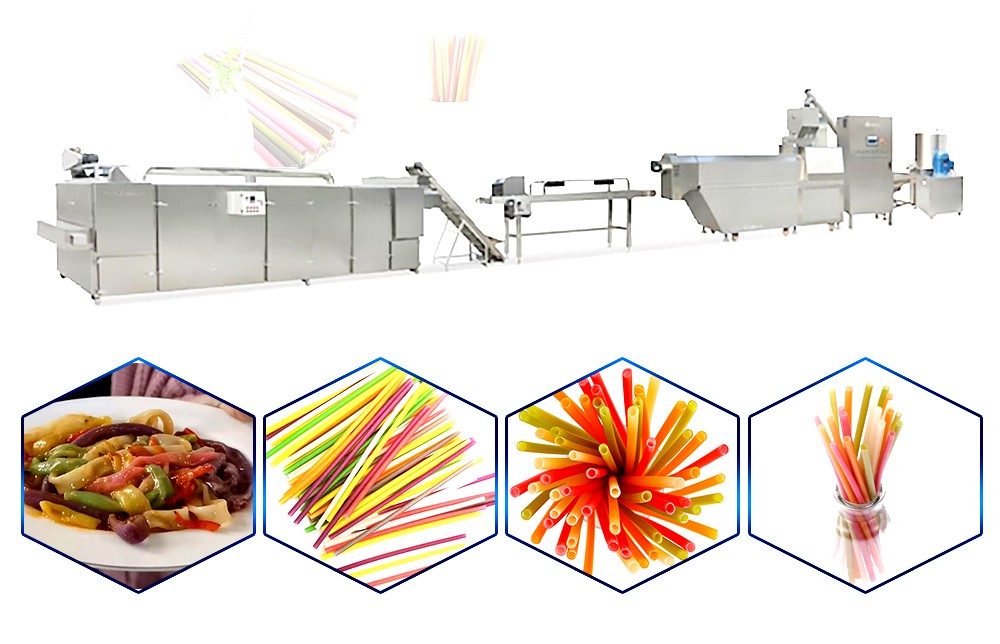

Biodegradable Rice Drinking Straw Processing Line Manufacturing Process

The edible straw processing production line uses flour, corn starch, tapioca starch, potato starch, potato whole wheat flour as raw materials, and is made into a blank of various sizes by a twin-screw extruder, and then dried to form a straw with a smooth surface and a realistic shape. Our unit screw combination technology and precise control of the production process can make your raw material selection wider, product quality higher and variety. A twin-screw extruder can complete the process of mixing, cooking, and extrusion.

BIODEGRADABLE RICE DRINKING STRAW PROCESSING LINE MANUFACTURING PROCESS

BIODEGRADABLE RICE DRINKING STRAW PROCESSING LINE MANUFACTURING PROCESS

Equipment : Mixing machine → Screw Hoister → Extruder → Cooler→Special cutting machine → Drying equipment

→ Packaging Machine

BIODEGRADABLE RICE DRINKING STRAW MANUFACTURING PROJECT REPORT

BIODEGRADABLE RICE DRINKING STRAW MANUFACTURING PROJECT REPORT

|

1 |

Mix: |

Mix rice flour, tapioca flour and water in proportion: Raw Materials:Flour, corn starch, tapioca starch, potato starch, potato whole wheat flour as raw materials |

|

2 |

Screw Conveyor |

Convey the stirred materials to the next machine-the extruder.The motor is used for power screw conveying to ensure convenient and fast feeding. |

|

3 |

Single screw Extruder/Double Screw Extruder |

Main machine for rice drinking straw making machine ,Rice, cassava, etc. can be used as raw materials to produce edible and degradable rice straw equipment. Extrusion, curing, forming. |

|

4 |

Cooler |

Lengthen the cooler with a fan to quickly reduce the temperature of the straw material. |

|

5 |

Special cutting machine |

Cutting the rice straw, the cutter speed was adjustable, the length of the straw can be adjusted .There 2 type knife working together,then the head of the cut straw is flat, and another end of straw is beveled.which more convenient for drinking. |

|

6 |

Drying equipment |

Drying the shaped rice straws for later packaging and transportation. Drying time 2-3H Tempreture: 70-80 degree |