What Is Wafer Biscuit Production Line

Wafer biscuit production line refers to the mechanical equipment used to produce wafer biscuit. It is a complete system including the different processes and stages involved in wafer biscuit production. The line usually starts by mixing the ingredients for a wafer batter, which may include flour, sugar, eggs, and flavorings. Then spread the batter evenly on the baking sheet or mold. These molds go through the oven to toast the wafer sheets. After baking, the wafer sheets are cooled and cream, chocolate or other fillings are spread between the layers to create a sandwich wafer. The filled wafer sheets are then cut into the desired shape and size. The cutting step is usually followed by a process called buttercream, in which cream or filling is spread on top of the wafer sheet to create the final wafer. The last step in the line is usually packaging, where the biscuits are individually wrapped or placed into packages for retail sale. A wafer biscuit production line usually consists of various machines, such as batter machines, ovens, cooling conveyors, buttering machines, cutting machines, packaging machines, etc. These machines are designed to automate the production process, increase efficiency and ensure consistent wafer quality.

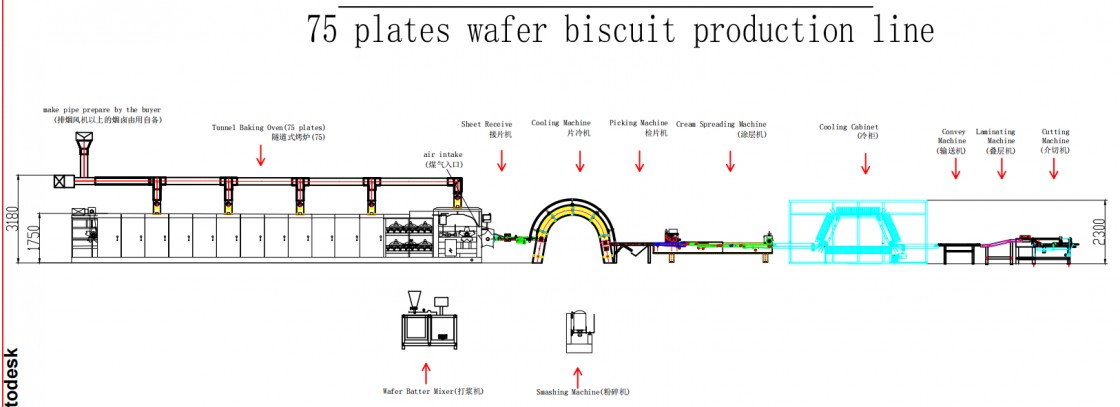

Flow Chart Of Wafer Biscuit Production Line

Parameter Of Wafer Making Machines

|

Model |

27 |

33 |

39 |

45 |

51 |

65 |

75 |

100 |

|

Oven Length (Mm) |

6000 |

7150 |

8300 |

9450 |

10600 |

13300 |

15000 |

20000 |

|

Production Line Length (Mm) |

22000 |

23150 |

24300 |

25450 |

26600 |

29300 |

38500 |

44350 |

|

Oven Power (Kw) |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

8.12 |

24 |

|

Consumption Of Liquefied Gas (Kg/h) |

13 |

15 |

19 |

23 |

27 |

32 |

45 |

50 |

|

Natural Gas Consumption (m³/h) |

16 |

21 |

25 |

30 |

35 |

45 |

58 |

67 |

|

Electric Heating Power (Kw) |

14 |

17 |

20 |

23 |

26 |

33 |

45 |

78.8 |

|

Output (Kg/h) |

90 |

110 |

130 |

150 |

170 |

215 |

300 |

780 |

What’s The Function Of Wafer Biscuit Production Line

Wafer biscuit production line is a complete set of mechanical equipment for wafer biscuit production. It is designed to handle every stage of the production process, from the preparation of the batter to the packaging of the biscuits.

Some of the machines that make up a wafer biscuit production line include:

- Batter Mixer – A machine used to mix batter ingredients such as flour, sugar, eggs and water.

- Wafer Sheet Baking Oven – This oven is used to bake wafer sheets to the desired thickness and texture.

- Cooling Conveyor – Conveyor designed to cool toasted wafer sheets and bring them to room temperature.

- Cutter - A machine used to cut wafer sheets into desired shapes and sizes.

- Cream machine - a machine for spreading cream fillings on wafer layers.

- Biscuit Press - A machine that presses wafer sheets and cream together to form biscuits.

- Slicer – A machine that cuts biscuits to the desired size.

- Packaging Machines - machines used to pack biscuits into different packages or containers.

The wafer biscuit production line is automated, which means it can produce large quantities of biscuits in a short period of time. It's also highly efficient and can produce biscuits of all shapes, sizes and flavors.

Advantages Of Wafer Making Machines

|

Increased Production Capacity |

Compared with manual production methods, the wafer machine can significantly increase the production capacity of wafer biscuits. These machines can produce large quantities of wafer biscuits in a relatively short period of time, enabling manufacturers to meet high demand and increase supply to the market. |

|

Consistent Quality |

Wafer machines are designed to ensure consistent quality in the production of wafer biscuits. The automated process ensures uniform thickness and texture of the wafer sheet, which contributes to the overall quality and taste of the biscuit. This helps maintain customer satisfaction and loyalty. |

|

Improve Efficiency |

The wafer machine simplifies the production process by automating the various steps of batter mixing, baking, cooling, filling, cutting and packaging. This reduces the need for manual labor and increases the overall efficiency of the line. It also eliminates the possibility of human error, thereby increasing productivity and reducing operating costs. |

|

Cost-Effective Operation |

By automating the production process, wafer fabrication machines can reduce labor costs and improve overall operational efficiency. Manufacturers can optimize the use of resources and minimize waste, resulting in cost savings in the long run. These machines require minimal maintenance and can run continuously for long periods of time, maximizing production. |

|

Versatility And Customization |

Wafer fabrication machines are flexible in terms of product variety and customization. They can produce wafers in various shapes, sizes and flavors to suit different consumer preferences. Manufacturers can also easily adjust the parameters of the machine to produce wafer sheets of different textures and thicknesses. This allows for innovation and the introduction of new product variants to meet market demands. |

|

Hygiene And Food Safety |

The wafer machine has been designed with hygiene and food safety standards in mind. They are made from food-grade materials and most components are easy to clean and maintain. This helps to ensure the production of safe and hygienic wafers that comply with regulations and standards. |

Overall, wafer machines offer numerous advantages in terms of increased production capacity, consistent quality, increased efficiency, reduced operating costs, versatility, customization, and adherence to hygiene and food safety standards. These advantages make the wafer maker a valuable investment for manufacturers in the wafer biscuit industry.

Wafer Biscuit Product Display

Wafer biscuits are thin, brittle biscuits usually made from a batter of flour, sugar, eggs, and butter. Known for their light and creamy texture, they are often layered with fillings such as chocolate, vanilla or hazelnut paste. Wafer biscuits are a popular snack that can be enjoyed on their own or with ice cream, coffee or tea.

These cookies are available in a variety of shapes and sizes, including round, square, and rectangular. They can be plain or decorated with patterns or designs that add visual appeal to the product. Some wafer variants include flavored fillings such as strawberry or caramel, giving consumers a choice of different flavors.

Wafer biscuits come in different packaging options, from individual portions to family packs. They are usually packaged in airtight containers or wrapped in foil or plastic to keep them crunchy and prevent moisture absorption.

Due to their versatility, wafer biscuits are used in a variety of dessert recipes and as an ingredient in ice cream sandwiches or cake decorations. They are also popular in some regions for religious holidays, such as using crepes when preparing communion crepes.

Overall, wafers offer a light and crunchy snacking option in a variety of flavors and packaging options, making them a popular choice among consumers of all ages.