What Is The Classification And Development Trend Of Instant Noodle Production Line?

The instant noodle production line equipment produced by Shandong Loyal Industrial Co., Ltd. is very popular among noodle-making enterprises in the market.

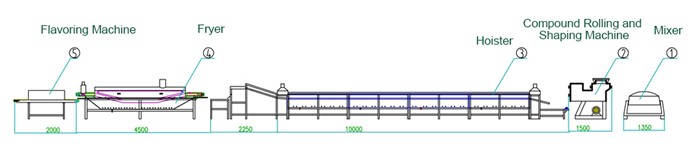

Full automatic instant noodle production line:

Mixer-Compound Rolling and Shaping Machine- Hoister- Fryer- Flavoring machine

There is no uniform regulation on the classification, and there are four classification methods generally recognized by various documents.

There is no uniform regulation on the classification, and there are four classification methods generally recognized by various documents.

(1) According to the drying process of instant noodles making machine processing line:

It is divided into fried instant noodle production line, hot-air dried instant noodle and boiled instant noodle.

1. Fried instant noodles

The drying speed is fast (about 70s to complete the drying), and the gelatinization degree is high (the starch gelatinization rate is more than 85%). The noodles have a porous interior due to rapid evaporation and dehydration in a short time, so the product has good rehydration and is in wastewater. It can be eaten after soaking for 3 minutes, with high convenience and pleasant frying fragrance. But because the product contains 20%-24% oil, the cost is high. In addition, despite the use of palm oil with a higher content of saturated fatty acids. However, after a period of storage, oxidative rancidity will still occur, resulting in greasy taste, which significantly reduces the taste and taste of the product, so the storage period of fried instant noodles is shorter.

2. Hot air drying instant noodles

The steamed and gelatinized wet noodles are dehydrated and dried at a temperature of 70-90. Because no oil is used, the cost is low, it is not easy to oxidize and rancid, and the storage time is long. Due to the low drying temperature, the drying time is long, the gelatinization degree is low, the internal porosity of the noodles is poor, the rehydration time is long when eating, and the convenience is poor.

3. Boiled instant noodles

Boiled instant noodles (also known as fresh instant noodles), it caters to the tastes of different consumers and meets the consumption requirements of different grades. Convenient to eat, boiled instant noodles have more advantages over air-dried noodles and fried instant noodles: its rehydration time is short and it is more convenient to eat: long-term consumption without frying is good for human health, especially popular among young people. : There are many ways to eat, you can make noodle soup, cold salad, or stir-fry. Each way of eating has a different taste.

(2) According to the packaging method

It can be divided into three types: bag, cup and bowl.

Our country is currently dominated by bags and bowls. The bag is low in cost, easy to store and transport, and tableware is needed for eating, so its convenience is not as good as bowls and cups.

Bowls and cups of instant noodles have better convenience due to their own tableware, but because the packaging container is more expensive, the cost and price of this product are higher.

At present, the recycling rate of various packaging materials used for packaging instant noodles in my country is low, which will cause environmental pollution.

(3) According to product flavor

It can be divided into several types, such as Chinese-style soy sauce fried noodles, scallion-flavored shrimp noodles: Japanese-style soy-flavored thick noodles, curry soba noodles: and according to different needs, different nutrients are added to the instant noodle production line, such as corn instant noodles, Mung bean instant noodles, soy flour instant noodles or other grains, beans instant noodles, etc.

(4) According to the shape of instant noodles

It can be divided into square instant noodles and round instant noodles.

The development trend of commercial instant noodle production line:

(1) Using new technology and instant noodle production line equipment instead of frying and drying, and the noodles have good rehydration.

For example, high-temperature hot air drying, microwave heating drying, ordinary drying and frying drying are combined to reduce the oil content of the product and extend the shelf life.

(2) Adopt new formula

Some additives such as modified starch and propylene glycol alginate can be added to improve taste and rehydration.

(3) To produce high-nutrition instant noodles, add vitamins, lysine and other substances that are lacking in wheat flour to make nutrition more comprehensive and richer.

(4) Aseptic packaging of instant noodle production line and soft canned soup have also become an inevitable trend