What are the advantages of corn flakes production line?

Corn flakes are a new type of breakfast cereal that has been welcomed by many consumers and has become one of the most popular breakfast cereals, with a very high market demand and future market prospects to look forward to.

As a specialist cornflake manufacturer, we were fully aware of the potential of the industry and therefore needed to use better equipment to improve the quality and production, and we decided to use the Corn Flakes Production Line, which is well known in the industry.

After a period of use, we have come to fully recognise the machine as having advantages that are unmatched by traditional equipment.

What are the advantages of the cornflake production line?

1. The production line realises fully automatic production, with very high production efficiency and high output.

2. All the equipment in the production line is made of food grade stainless steel, which is resistant to wear and corrosion and has a long service life.

3. The equipment can be used flexibly, not only for the whole production line, but also for individual equipment.

4. It can process and produce many kinds of breakfast cereals, which is widely used.

5. Using plc control system, easy to operate, the whole production line only needs 1-2 people to complete the processing production.

With its significant advantages and superior performance, the cornflake production line has brought great changes to our processing and production, not only effectively improving production and quality, but also reducing labour costs and production costs, allowing us to further increase our profits and further improve our competitiveness in the market, the cornflake production line can meet our production needs in many ways.

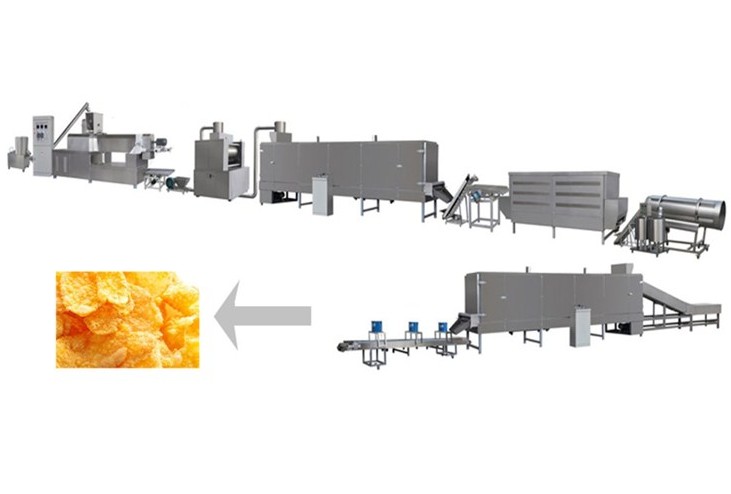

The cornflake production line is a combination of mixer, conveyor, extruder, dryer, flavouring machine, oven and packaging machine. All production processes such as mixing, extrusion, cutting, pre-drying, pressing, high temperature baking, flavouring and packaging can be completed automatically, abandoning the disadvantages of traditional processing methods and providing superior performance.

Corn flake production lines versus traditional processing methods.

1. The cornflake production line uses advanced extrusion technology to ensure that the cornflakes are cooked without any puffing, resulting in a richer taste and more comprehensive nutrition than can be achieved by traditional processing methods.

2. In terms of production efficiency, the cornflake production line is fully automated and far more efficient than traditional processing methods, which means we can produce and process more products to meet more orders.

3. In terms of hygiene quality, the food-grade stainless steel and self-cleaning system of the cornflake production line can ensure the hygiene quality of the production process, and the production process is pollution-free, without "three waste" problems, which can effectively help us achieve green production.

The fact that the various machines in the Corn Flakes Production Line work together in all production processes, even without much human intervention, not only helps us to expand our market, but also to provide consumers with better quality corn flakes, which is why we decided to use Corn Flakes Production Line for a long time and have become friends with the company.

We also hope that engineers will develop more quality equipment to further promote the development of the food processing industry and provide consumers with more good quality food at a lower price!