Cereal breakfast foods mainly refer to corn cereals manufacturing processed with modern technology using cereals (corn, rice, wheat, oats, etc.) as the main raw materials.Breakfast corn cereal is a kind of crispy food, with the characteristics of hard to be steeped broken and strong grain taste. Breakfast Cereal Making Machine includes mixing, extruding ,drying,sugar coating and drying.breakfast cereal production line can be used as a snack or served with milk and coffee.Change molds and choose the right process to produce circles, balls, sheets, stars, letters and other products,and produce core filling snack food, filling biscuit ,nutrition breakfast, corn flakes and other puffed foods.

Breakfast Cereal Making Machine

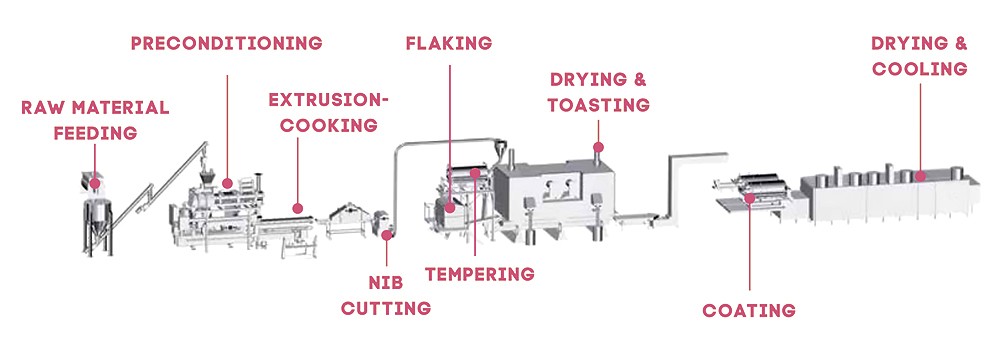

how is cereal made in a factory?

Breakfast cereal production process is the breakfast cereal suppliers first put the raw material into the double screw extruder, the breakfast material in the extrusion puffing machine under the action of the rotating screw movement between the material, the material and the barrel of the screw, etc. to generate friction, the material will be constantly cut, squeezed and stirred, the internal temperature of the extruder will increase, the pressure will increase, at high temperature and pressure, the material will be cooked to a paste, double screw extruder In the pressure becomes greater, the paste material will be ejected from the mold, the moisture in the material will quickly vaporize and puffed, through the mold close to the rotation of the cutting tool for cutting and shaping, you can form a variety of shapes of corn cereal. The cereales corn flakes into the dryer, and then drying, cooling, drying temperature needs to be about 120 °, through air cooling, breakfast cereaks snacks after drying, in which the moisture should be about 3%, so that the shelf life of puffed food to extend, food baking will produce flavor, the quality of food can be improved.

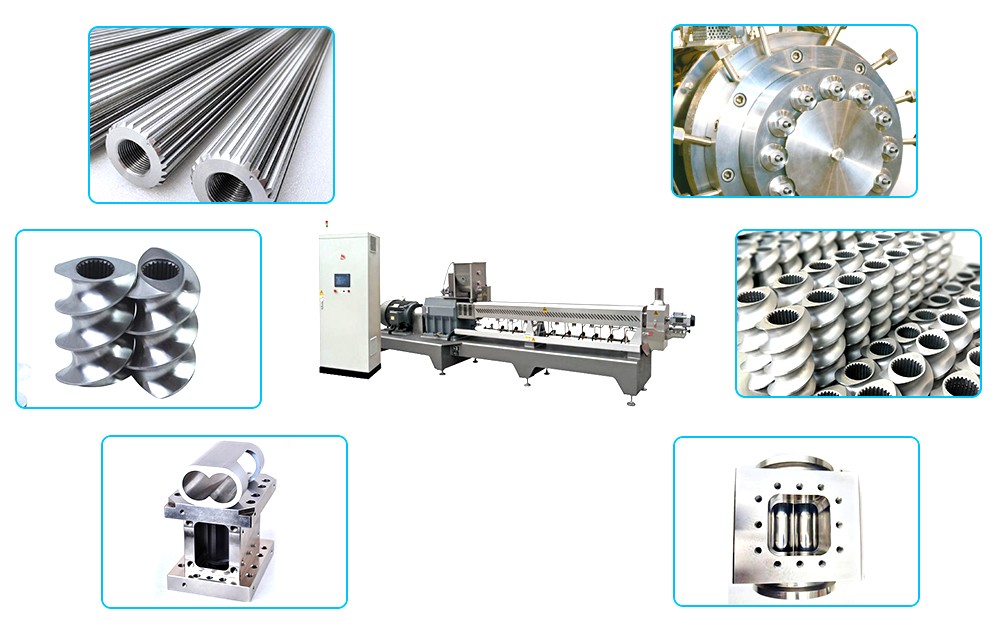

Breakfast Cereal Extruder

breakfast cereal making machine manufacturing process

| Function Of Each Breakfast Cereal Machine | ||

|

1 |

Flour Mixer |

Mixing materials |

|

2 |

Screw Conveyor |

Transfer cereals snacks raw materials from Mixer to Twin screw Extruder |

|

3 |

Twin screw extruder |

Extruding corn cereals |

|

4 |

Air Conveyor |

Transfer cereals snacks to dryer |

|

5 |

Commercial food dryer |

Drying process in food industry to remove moisture |

|

6 |

Air Conveyor |

Transfer cereals snacks to Sugar Sprayer |

|

7 |

Sugar Sprayer |

Spraying sugar on cereals snacks surface |

|

8 |

Commercial food dryer |

Drying again to remove sugar moisture |

|

9 |

Cooling machine |

Cooling cereals snacks with cooling fan |

|

10 |

cereals snacks packaging |

Packing cereales corn flakes in bags |

breakfast cereal production line Flow chart design

Raw material formulating-Mixer-double screw extruder----air conveyor--dryer-----air conveyor--sugar coating line--- dryer---cooling conveyor-Packing

Breakfast Cereal Processing Line

Technical Parameters For breakfast cereal production line

|

Different model for sale of cereal making machine |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

LY65 Corn flake machine |

140kw |

90kw |

100-150g/h |

29000x1200x2200mm |

|

LY70L Corn flake machine |

160kw |

120kw |

200-250kg/h |

31000x1500x2200mm |

|

LY85 Corn flake machine |

180kw |

140kw |

300-500kg/h |

33000x3500x4300mm |

|

LY75 Corn flake machine |

180kw |

140kw |

300-500kg/h |

42000*2000*2800mm |

|

LY95 Corn flake machine |

300kw |

260kw |

800-1000kg/h |

46200*3000*2800mm |

Breakfast Cereal Processing Line Details

cereal making machine manufacturing cost

| Price Of Breakfast Cereal Processing Line | ||

|

cereal production process Price |

Electrical heating type Breakfast cereals for sale |

Gas/Diesel heating type Breakfast cereals for sale |

|

LY65 |

$40000 |

$48000 |

|

LY70 |

$47000 |

$53000 |

|

LY85 |

$120000 |

$140000 |

|

LY75 |

$156000 |

$156000 |

|

LY95 |

$600000 |

$700000 |

cereal snacks manufacturing project report

|

The Advantages of cereals snacks machine: |

|

|

1 |

Twin screw extruder for Cereal breakfast making machines adopts the extrusion technology. |

|

2 |

Extrusion equipment tends to have good continuous working performance and high production efficiency, thus reducing production costs. |

|

3 |

It can improve the textural characteristics, density and hydrophobicity of food materials, thus improving the taste and flavour of products, which is conducive to the refinement of coarse grains and makes them more acceptable to people. |

|

4 |

It can improve the textural characteristics, density and hydrophobicity of food materials, thus improving the taste and flavour of products, which is conducive to the refinement of coarse grains and makes them more acceptable to people. |

|

5 |

There is almost no waste during the production process, only a small amount of raw material is discharged during start-up and shutdown, thus reducing material waste. The extrusion process is a short process and the material is heated for a short period of time, thus preserving the maximum nutritional value of the material. |

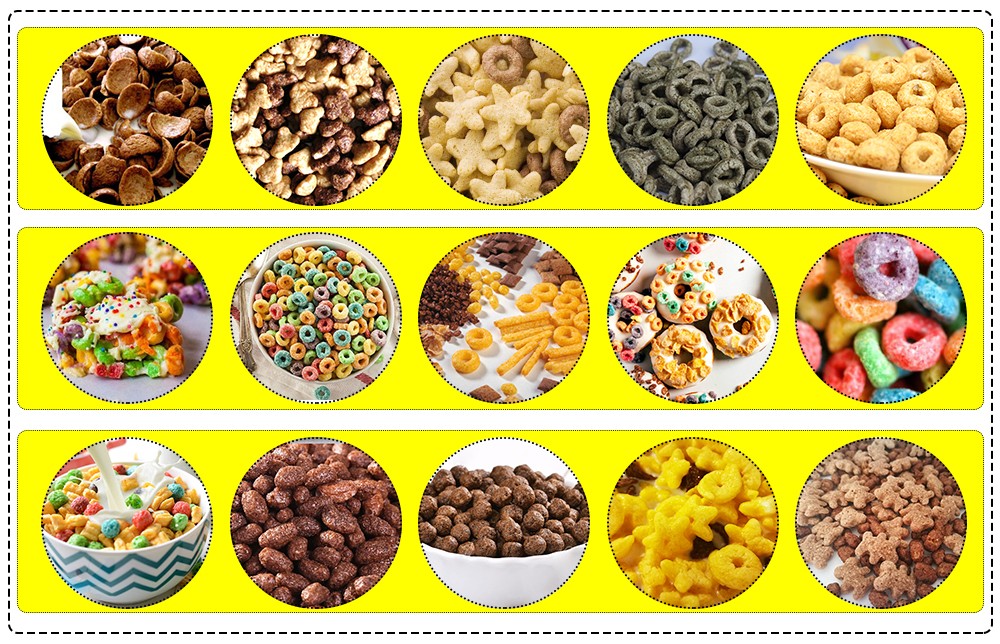

Breakfast Cereal Processing Line Samples

a Wide Choice Of Breakfast Cereals Ingredients

Direct Expanded Cereals

Direct expanded breakfast cereals are cut at the axe of the extruder die to form shapes such as loops, alphabet letters, balls, curls, squares, stars, petals and rings.

| Breakfast Cereal Formula | ||

|

Rice flour: 43% |

Corn flour: 30% |

Wheat Flour :10% |

|

chocolate powder(17%) |

Water: 5% |

Calcium carbonate 0.2% |

|

Soy lecithin 0.4% |

Glucose syrup 2% |

|

|

Feeding amount 100 kg/h; Screw speed 1000r /m in The temperature of the barrel cavity is 70℃/180/℃/200℃; Baking temperature is 180℃ Time 20min. |

||

Breakfast Cereal Processing Line Finished Products

Cereal vs Cornflakes - What's the difference?

| Differenece Between Cereal And Corn Flakes | |

|

Corn flakes |

Breakfast cereals |

|

Hign cost |

Lower cost |

|

More space |

Less space |

|

Corn Flakes' main ingredient is corn |

It is made mainly from grains such as rice, wheat, and barley |

|

With flaking machine and baking machine |

Without flaking machine and baking machine |

|

After extruder is corn pellet |

After extruder is puff snacks |

Loyal Company before sales service for corn flake machine:

a.) We provide you the suitable solution,which is useful and convenient

b.) We produced the product you need in our factory,you can buy it without any hesitate.

c.) We provide you the factory design and processing line layout and also design for water and electric and gas etc.

d.) With much experienced technical team,we can meet customer personalized requirement,produce the customized machine for you

Loyal Company after sales service for corn flake machine:

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

Customer Cases for Corn Flakes Processing Machine in 2021

The international market share of Shandong Loyal Industrial's exports has steadily increased. According to the export goods trade data in 2021, Loyal's international export market share is 86.5%, of which the breakfast corn flakes production line and the breakfast cereal production line's export market share in Africa will have a market share of 20.8%, and the breakfast corn flakes production line and the breakfast cereal production line's export market share in the Americas will have a market share of 30.2%.

Breakfast corn flakes production line The breakfast cereal production line export market share in Asia is 35.5%, if you are interested in the breakfast corn flakes production line, please contact us immediately, we will provide you with the most cost-effective turnkey solution

|

Cooperated Customer Request Engineer Installation At 2021 |

|

|

1 |

China 300t/year industrial corn flakes manufacturing machine |

|

2 |

1T/H Corn Flakes Processing Machine for sale in Puerto Rico |

|

3 |

1T/H Corn Flakes Processing Machine for sale in Bolivia |

|

4 |

Senegal 1T/H corn flakes processing steps corn flakes Production Line |

|

5 |

1T/H Corn Flakes Processing Machine for sale in Côte d'Ivoire |

|

Cooperated Customer with Corn Flakes Processing Machine Technology At 2021 |

|

|

6 |

1T/H Corn Flakes Processing Machine sold in Russia |

|

7 |

1T/H Corn Flakes Processing Machine for sale in Uzbekistan |

|

8 |

1000kg/h industrial automatic corn flakes machine for sale in Senegal |

|

9 |

Mozambique 1T/H corn flakes manufacturing process |

|

10 |

Bangladesh 2t/h Industrial corn flakes making process |

|

11 |

1T/H Thai corn flakes processing line |

|

12 |

Uzbekistan 1T/H corn flakes production |

|

13 |

USA 1T/H corn flakes processing machine |

|

14 |

800kh/h industrial corn flakes processing line for sale in Nigeria |

|

Dealed Customer Have Technology Of Corn Flakes Production Process Line At 2021 |

|

|

15 |

Algerian corn flakes 300kg/h production line |

|

16 |

Sudan 200kg/h corn flakes line cereal manufacturing plant |

|

17 |

Moldova small 200kg/h flakes production line |

|

18 |

200kg/h milk breakfast cereal equipment sold in Ukraine |

|

19 |

Nigeria 150KG/H cereal processing technology |

|

20 |

Austria sells industrial processing of breakfast cereals 100kg/h |

|

21 |

Nigeria 150KG/H least processed breakfast cereal machinery |

|

Dealed Customer Have Formula Of corn flakes processing line At 2021 |

|

|

22 |

Breakfast cereal manufacturing process for sale in Pakistan 100kg/h |

|

23 |

Austria sells cereal processing technology 100kg/h |

|

24 |

50KG/H small cereal manufacturing process for sale in Botswana |

|

25 |

Sudan 50kg/h small cereal manufacturing plant |

|

26 |

Algerian kellogg's manufacturing process 300kg/h production line |

|

27 |

300kg/h Technologies and granola manufacturing equipment Involved in Breakfast Cereal Production and Processing sold in Ukraine |

|

28 |

200kg/h Technologies and granola manufacturing equipment in Cereal Processing and Production for sale in Nigeri |

Breakfast Cereal Production and Processing Working Video