Industrial vegetable dryer machine adopts heat pump host to absorb external heat or waste gas heat, and then recovers the drying work through compressor.

vegetable drying machine absorbs heat from the surrounding environment and transfers it to the drying room or drying area to transfer the energy to the vegetable dryer box. The hot air in the drying box is heated through repeated circulation and absorbs the moisture in the material, so that it can be cooled and humidified, and the hot air can be discharged or condensed, Take the moisture away from the material, and finally realize the continuous drying of the material.

The vegetable drying machine is mainly composed of heat pump, drying room, trolley, tray, etc., except for motor, electrical appliances, etc. the box is made of food grade stainless steel (SUS304).

Applications of Industrial Vegetable Dryers in Manufacturers

HOW TO DRY VEGETABLES IN THE VEGETABLE DRYER MACHINE?——WORKING PRINCIPLE

The Industrial vegetable dryer machine includes a high temperature heat pump unit. Its working principle is:

|

1. The refrigerant is compressed into high temperature and high pressure gas by the compressor, |

|

2. Enter the condenser to condense the heat of liquefaction, which is used to heat the drying chamber and provide the temperature of the drying chamber. |

|

3. The moisture in the material is evaporated by hot air. |

|

4. The evaporated water vapor is taken away by the dehumidification system to achieve the purpose of dehumidification of dry materials. |

|

5The dehumidification system adopts heat recovery device. Using the recovered heat to heat the fresh air can save 60%. %-70% fresh air preheating energy consumption to further save energy. |

Industrial vegetable dryer machine Manufacturing Process

TECHNICAL PARAMETER FOR INDUSTRIAL VEGETABLE DRYER MACHINE DESIGN

|

Model |

IVDM-3P |

IVDM-6P |

IVDM-8P |

IVDM-16P |

IVDM-32P |

|

Power |

2.7kw/h |

6.5kw/h |

8kw/h |

20kw/h |

37.2kw/h |

|

Capacity |

0.2-0.3 |

0.5-0.8 |

1.0-1.5 |

2.0-3.0 |

5.0-6.0 |

|

ton/batch |

ton/batch |

ton/batch |

ton/h |

ton/h |

|

|

Trolley quantity |

0 |

4 |

8 |

16 |

40 |

|

Trolley size |

0 |

1057*805*1740mm |

|||

|

Tray quantity |

30 |

48 |

96 |

192 |

480 |

|

Tray size |

800*600mm |

1000*800mm |

|||

|

Dryer size |

2.4*1.1*2.2m |

3.8*2.5*2.2m |

4.8*2.5*2.2m |

9.5*2.5*2.2m |

13*4*2.3m |

Industrial vegetable dryer machine Production equipment

WHAT ARE THE ADVANTAGES OF VEGETABLE DRYER MACHINE DURING PRODUCTION PROCESS?

|

1.Energy saving: vegetable drying machine adopt heat pump technology, absorb heat from air and recovery waste heat at the same time Adopt close dehumidify + circulating drying type, saving operating cost; |

|

2.Vegetable Dryer Exact control temperature and humidity: The drying temperature of vegetable drying equipment can be easily controlled by PLC +Touch Screen control system. |

|

3.Uniform drying: vegetable drying equipment by using the forced ventilation function, there are partition sheet and fan motors inside the drying chamber to make sure hot air cycle, so the raw materials can be dried evenly.The temperature: 10-75°C, Max 75°C, similar nature drying. The baking plate dimensions and materials can customize as customer request. |

|

4.Commercial vegetable dryer has good drying quality.: During drying, the material does not craze, does not distortions, non-discoloring, never degenerate, non-oxidize, drying completely, with good rehydration, keep nutrient content; |

|

5.Industrial vegetable dryerr is safe and reliable operation: Automatic intelligent control, 24-hour continuous drying; Without waste gas and waste heat pollution,low noise |

|

6.Energy saving: vegetable drying machine adopt heat pump technology, absorb heat from air and recovery waste heat at the same time Adopt close dehumidify + circulating drying type, saving operating cost; |

|

7.Vegetable Dryer Exact control temperature and humidity: The drying temperature can be easily controlled by PLC +Touch Screen control system. |

Industrial vegetable dryer machine manufacturing equipment

HOW ABOUT THE APPLICATION OF VEGETABLE DRYING EQUIPMENT?

Industrial vegetable drying Processing sample

|

Dry vegetables like tomato, potato, garlic, ginger, onion, chilli, radish, lettuce, pumpkin, carrots, spinach, cassava, ... etc |

|

Dry fruits like apple, lemon, mango, plum, pineapple, apricot, pear, grape, banana, ...etc |

|

Dry fish, shrimp, sea cucumber,etc |

|

Dry meat:, Sausage, beef, duck, ham etc |

|

Dryer also it can dry noodle/ wooden /stick incense/herbs /flowers etc |

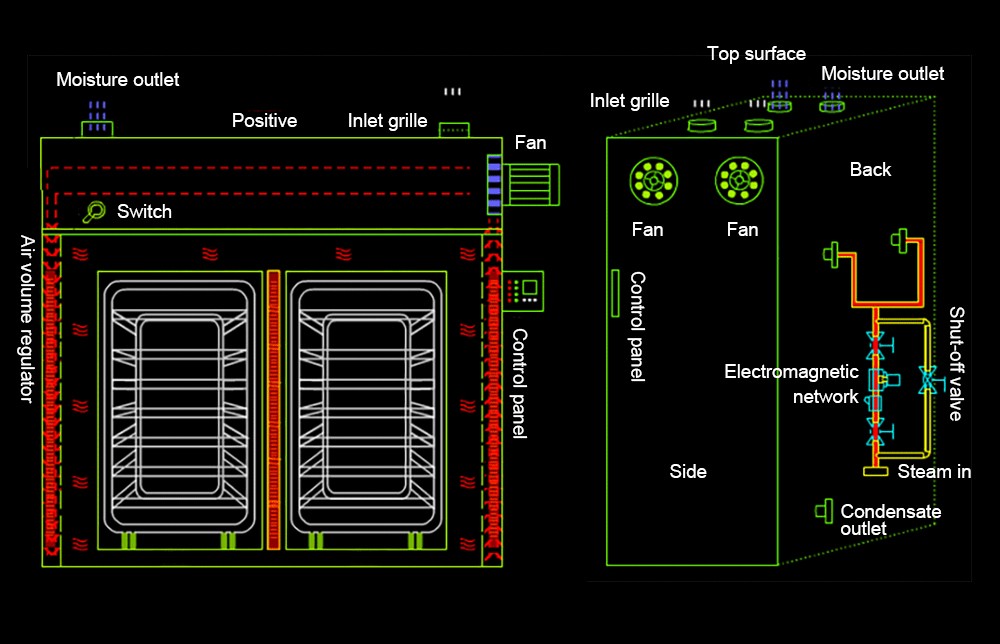

CAD of Industrial vegetable drying machine

What Kind Of Industrial Vegetable Dryer Machine Has Been Loyal Sold In 2021 ?

| Customer Case Of The Rose Petal Microwave Flower Drying Machine At 2021 |

| 100-150KG/H Rose Petal Microwave Flower Drying Machine For Sale Botswana |

| LY-5 Rose Petal Microwave Flower Drying Machine for sale Pakistan |

| 500kg/h high quality Rose Petal Microwave Flower Drying Machine Moldova |

| 100-150kg/h Rose Petal Microwave Flower Drying Machine for sale Ukraine |

| 200kg/h Rose Petal Microwave Flower Drying Machine for India |

| 1T/H Rose Petal Microwave Flower Drying Machine For Sale Puerto Rico |

| 500KG/HRose Petal Microwave Flower Drying Machine For Sale Dominica |

| 1T/H Rose Petal Microwave Flower Drying Machine in Senegal |

| Cooperated Customer Finished Plant Of Herb Drying Equipment At 2021 | |

| 1 | 1000kg/h Industrial Automatic Herb Drying Equipment For Sale In Senegal |

| 2 | Mozambique 1T/H Industrial Herb Drying Equipment Manufacturer |

| 3 | 1T/H Thai Herb Drying Machine |

OUR SERVICE & CUSTOMERS

Pre-service:

As an excellent and experienced vegetable dryer machine manufacturers, our company could provide customer with products and service with excellent quality and reasonable price

1. Give the customer a detailed description of the appropriate product, and serious answers to the questions raised by the customer

2. Make the suitable project as the customer requirement and make sure the industrial vegetable dryer is suitable for the material;

Sale service:

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3. Provide full set of documents as customer’s requirements.

After-sale service:

Provide considerate services to minimize clients’ worries.

1. Assist clients to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators;

4.Examine the equipment;

5.Take the initiative for troubleshooting immediately;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment:

1. Provide clients one-year warranty to make sure the machine could work well;

2. Send every client a preferential quotation by e-mail.