Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.fast, efficient, safe and environmentally friendly.

The products baked by the microwave baking equipment keep its original color, the grains are puffed and crisp.

The micrwave baking macine foe dried fruit can achieve different functions such as drying, bakiing, sterilization (insecticidal) and puffing by adjusting microwave power, convey speed.

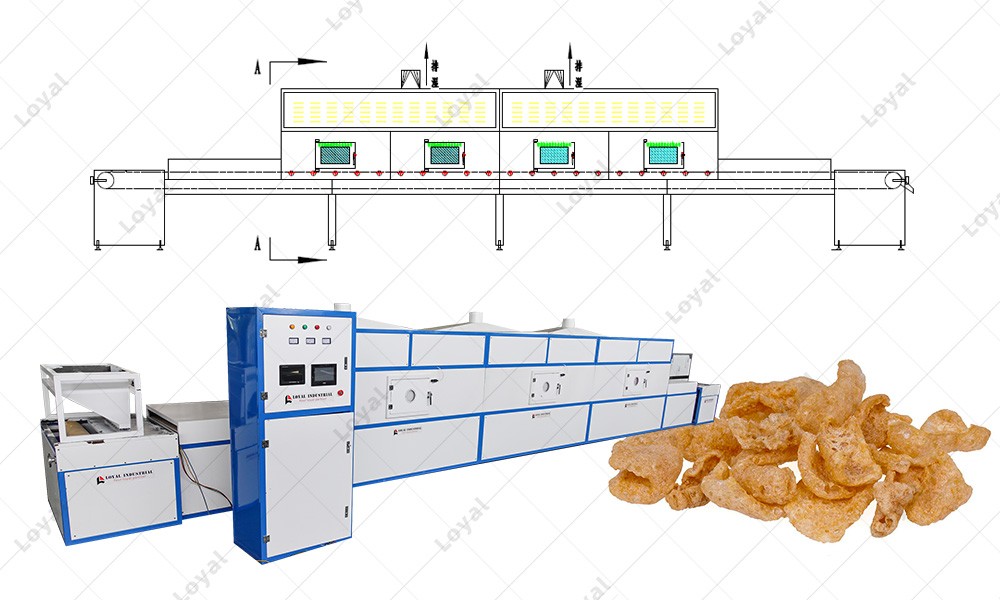

CAD of Continuous Microwave Puffed Pork Skin Microwave processing line

How Do They Make Puffed Pork Skin?

Industrial microwave ovens can quickly puff and cook pork rinds as a non-fried snack food. Traditionally, we need to use deep fried pork rinds so we can get crispy pork rinds. However, we can also use an industrial microwave to cook pork rinds quickly, without frying, which is healthier.

Our Continuous Microwave Puffed pork skin Microwave Machine blows out cookies in seconds.

The microwaved pork rind looked exactly like a shortbread fried in oil, but it didn't have any oily taste. The microwave puffing solution is less messy and faster because the pork skin doesn't get greasy. In addition, the biscuits retained a stronger pork rind aroma.

Then according to the recipe of microwave port skin, build an industrial microwave system, and industrial microwave manufacturers can make delicious pork skin!

Multifunctional microwave puffed pork rind production equipment

Technical Parameters And Price Of Continuous Microwave Puffed Pork Skin Microwave Machine

|

Technical Parameters And Price Of Continuous Microwave Puffed Pork Skin Microwave Machine |

|||

|

Type: |

Drying Oven |

Application: |

Low-Temperature Roasting Of Whole Grains |

|

Condition: |

New |

Place Of Origin: |

Shandong, China |

|

Brand Name: |

LY |

Voltage: |

380v/440v Customized |

|

Power: |

20-200kw |

Dimension(L*W*H): |

8640 *1200* 2200mm |

|

Key Selling Points: |

High Productivity |

Warranty: |

1 Year |

|

Applicable Industries: |

Food & Beverage Factory, Farms, Food & Beverage Shops |

Marketing Type: |

Ordinary Product |

|

Machinery Test Report: |

Provided |

Core Components: |

Motor, Plc |

|

Motor Brand: |

Abb |

Product Name: |

Microwave Grains Dryer |

The Application Of Continuous Microwave Puffed Pork Skin Microwave Machine

|

The Application Of Continuous Microwave Puffed Pork Skin Microwave Machine |

|

|

Prawn cracker drying sterilizing curing machine |

Shrimp crackers microwave drying sterilizing curing machine |

|

Prawn chips microwave drying sterilizing curing machine |

Dried shrimp chips microwave drying sterilizing curing machine |

|

Microwave prawn cracker microwave drying sterilizing curing machine |

Mung beans microwave drying sterilizing curing machine |

|

Buckwheat microwave drying sterilizing curing machine |

Red beans microwave drying sterilizing curing machine |

|

Pumpkin seeds microwave drying sterilizing curing machine |

Black sesame microwave drying sterilizing curing machine |

Continuous microwave puffed pork rind microwave machine customer factory production site

How To Choose Continuous Microwave Puffed Pork Skin Microwave Machine Of Different Models ?

|

The model about Continuous Microwave Puffed Pork Skin Microwave Machine |

|||||

|

No |

Model |

Power |

Dehydration Capacity |

Sterilization Capacity |

Size(L*W*H) |

|

1 |

Ly-12KWSP |

12KW |

12kg/h |

120-150kg/h |

7*0.84*1.75m |

|

2 |

Ly-20KWSP |

20KW |

20kg/h |

192-240kg/h |

9.4*0.84*1.75m |

|

3 |

Ly-30KWSP |

30KW |

30kg/h |

300-375kg/h |

11.7*0.84*1.75m |

|

4 |

Ly-40KWSP |

40KW |

40kg/h |

396-495kg/h |

10.52*1.06*1.75m |

|

5 |

Ly-50KWSP |

50KW |

50kg/h |

504-630kg/h |

11.7*1.06*1.75m |

|

6 |

Ly-60KWSP |

60KW |

60kg/h |

600-750kg/h |

12.86*1.06*1.75m |

|

7 |

Ly-70KWSP |

70KW |

70kg/h |

696-870kg/h |

14.03*1.06*1.75m |

|

8 |

Ly-80Kwsp |

80Kw |

80kg/h |

804-1000kg/h |

14.86*1.2*1.75m |

|

9 |

Ly-100Kwsp |

100Kw |

100kg/h |

1000-1250kg/h |

15.2*1.2*1.75m |

|

10 |

Ly-150Kwsp |

150Kw |

150kg/h |

1500-1875kg/h |

21.05*1.2*1.75m |

What Are The Advantages Of Continuous Microwave Puffed Pork Skin Microwave Machine?

|

Characteristics Of Continuous Microwave Puffed Pork Skin Microwave Machine |

||

|

1 |

Short puffing time and high output: |

Microwave directly acts on the shrimp slices, the energy loss is small, and the average puffing time is less than 1 minute. The conveyor belt quickly transports the shrimp pieces through the microwave cavity, and the output per unit time is much higher. |

|

2 |

The puffing effect is even: |

We just need to spread the shrimp slices on the conveyor belt. After processing, the bulk volume is about three times that of the original one, the output products are uniform, and there is no phenomenon of partial baking or no-puffing. The puffed shrimp slices keep the white and bright color as well as the prawn smell. |

|

3 |

Healthy and delicious: |

Compared with extrusion and frying, the microwave puffing process does not produce a series of chemical reactions, does not increase the fat, and better retains the original flavor. In addition, a shorter a few seconds puffing time greatly reduces the nutrient loss of the material.therefore, microwave puffing technology is also widely used in the processing of starchy foods (such as corn, glutinous rice, millet), protein foods (such as soybeans), and mixed foods (such as shrimp slices). |

|

4 |

Puffing and sterilization are completed at the same time: |

Microwave energy achieves satisfactory bactericidal effects. |

|

5 |

Energy saving and environmental protection: |

The microwave directly acts on the material, and the energy conversion rate is high, which saves the consumption of electric energy. No gas or waste is generated during the operation of the equipment. |

|

6 |

Easy to operate: |

Compared with the traditional method, loyal microwave equipment is ready to use, small footprint, no thermal inertia, flexible operation and convenient, microwave power can be adjusted according to actual production needs. |

|

Loyal microwave puffing machine adopts the plc automatic control system, combined with rotary speed control and timer set up, which saves a lot of labor. Microwave puffing machine is popular among snack manufacturers, and it is an innovation in modern snack production. |

||

High-efficiency microwave puffing pigskin sample process

Which Market Did The Loyal Industrial Continuous Microwave Puffed Pork Skin Microwave Machine?

|

Customer Case Of Powder Drying And Sterilizing Machine At 2021 |

|

|

1 |

100Kg/H Pork Skin Microwave Drying Sterilizing Curing Machine For Thailand Customer |

|

2 |

100Kg/H Puff Pork Skin Drying And Sterilizing Machine For Sale In Uzbekistan |

|

3 |

100KG/H microwave Puff Pork Skin microwave dryer microwave drying machine for sale in Nigeria |

|

4 |

20KW Buckwheat Microwave Drying Sterilizing Curing Machine for sale in Nigeria |

|

5 |

200KW Puff Pork Skin Microwave Drying Sterilizing Curing Machine for send to India |

|

6 |

1T/day food sterilizer equipment for chill powder to sale in Canada |

|

7. |

100kw shrimp crackers powder Microwave Drying Sterilizing Curing Machine send to Egypt |

|

Customer Case Of Powder Drying and Sterilizing Machine At 2021 |

|

|

1 |

200kg/h industrial microwave oven for sale in bolivia |

|

2 |

Mozambique 150kg/h industrial fish drying equipment to lithuania |

|

3 |

300kg/h industrial continuous belt dryer for sale in portugal |

|

4 |

Mozambique 250kg/h industrial seafood drying equipment |

|

5 |

60kw seafood industrial automatic industrial belt dryer for sale in |

|

Customer Have Factory Case Of Industrial Powder Drying and Sterilizing Machine At 2021 |

|

|

1 |

200KG/H industrial microwave oven for sale in Bolivia |

|

2 |

Mozambique 150KG/H industrial drying equipment |

|

3 |

300KG/H industrial continuous belt dryer for sale in Pakistan |

|

4 |

Mozambique 250KG/H industrial herbs leaces tea drying equipment |

|

5 |

150kw Oatmeal Microwave Drying Sterilizing Curing Machine sterilization in food processing sold to Russia |

|

6 |

200kw Soybean powder Microwave Drying Sterilizing Curing Machine for sale in Canada |