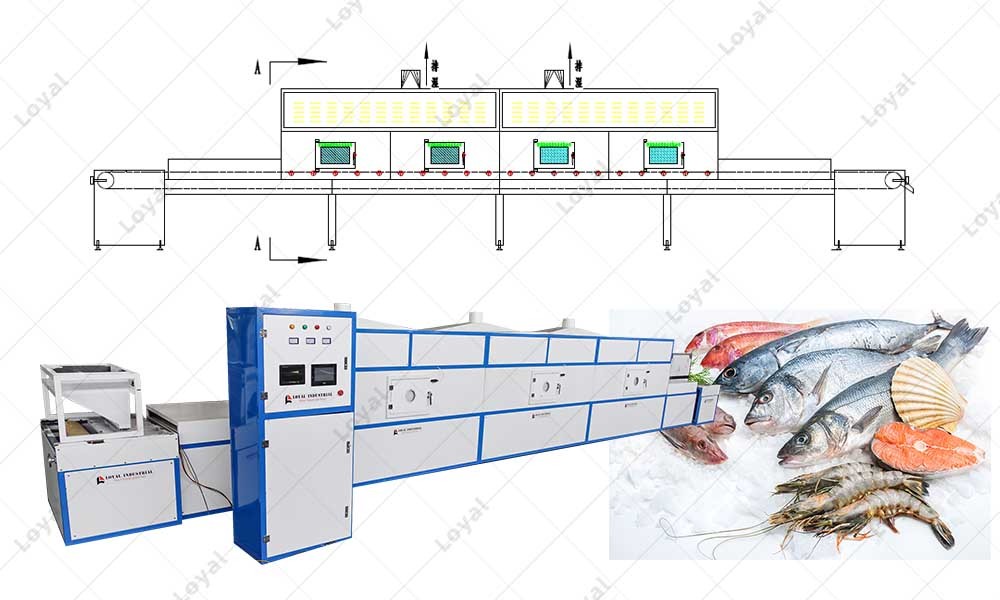

The whole thawing machine is made of 304 stainless steel. The operating mesh belt can be selected according to the size and characteristics of the product. The conventional mesh belt is made of stainless steel. The equipment can be designed as a lifting type according to the needs. It is convenient and can be configured differently according to the different needs of customers.

Application Of PLC Control System Microwave Frozen Shrimp Thawing Machine

|

Functions&Features |

|

|

Drying |

The microwave dryer is used to dry green tea leaf in a short time |

|

Sterilization |

The fungus, mycetes and others can be killed by the microwave dryer during the drying process. |

|

Fast and evenly |

The microwave dryer can change to be heat within several seconds,so the equipment is very efficent. |

|

keeping fresh |

The sterilization is with lower temp, so the color,taste and nutrition of the tea can be protected well. |

|

Safe |

The microwave is passing in the metal covered rooms and waveguide without leaking. It will not generate extra heat and pollution. |

|

Fast and evenly |

The PLC system is simple, stable, safe and friendly,so it is convenient to use. |

|

Advantages of Microwave Frozen Seafood Thawing Machine |

|

|

1. |

The whole machine is made of 304 stainless steel, which fully meets the national food production safety requirements. |

|

2. |

Various heating methods are available (steam or electric heating). |

|

3. |

The temperature can be adjusted, the conveying adopts frequency conversion motor, and the speed is adjustable by frequency conversion. Can be adjusted for different products. |

|

4. |

The whole machine is designed as an independent inner tank structure, and the outer frame is welded, which is strong and durable, and prolongs the service life of the equipment. The advantages of the inner tank structure are firstly easy to clean and ensure the cleanliness of the equipment. Secondly, the mesh belt is not limited by the frame, even if a serious collision is damaged, it will not affect the conveying of the mesh belt. |

|

5. |

In order to ensure the uniform temperature of the thawing tank, a circulating pump is used to force the circulation of the cold water in the tank. |

|

6. |

In order to ensure that the thawed products are clean, there is a cold water spray in the middle of the mesh belt in the thawing section. The impurities brought into the thawing tank by the product will be circulated in the outer water tank for sufficient time to precipitate, so as to reduce the number of times of cleaning the thawing tank. |

|

7. |

The machine adopts frequency converter to adjust the stepping speed of the conveyor belt with high accuracy. |

|

8. |

Both sides of the chain of the whole machine are equipped with protective devices to prevent the product from being involved in the chain and causing damage to the product. |

|

9. |

The bottom end of the machine is equipped with a ground angle, and the height of the ground angle can be adjusted to keep the equipment and the ground stable. |

|

10. |

The conveyor chain plate of the defrosting line is equipped with an integral chain lifting design. (The conveyor mesh belt can be lifted as a whole to facilitate customer hygiene and cleaning); the overall lifting method adopts the chain lifting design (the upper and lower limit controls are also installed on the electrical appliance), so that the overall operation of the equipment is smooth and safer. |

Microwave Frozen Seafood Thawing Machine In Production Workshop

|

Technical equipment |

||

|

Equipment Model |

LY-Microwave Drying Equipment |

LY-Microwave Drying Equipment |

|

Operating frequency |

2450±50MHZ |

2450±50MHZ |

|

Rated inputapparent power |

≤60KW |

≥120KW |

|

Microwave output |

≥50KW |

≤110KW |

|

Temperature |

70-200℃(controlled) |

70-200℃(controlled) |

|

Type of cooling |

Water-Cooling/Air cooling |

Water-Cooling/Air cooling |

|

Inlet and outlet height |

40-100mm |

40-100mm |

|

Height of conveyor |

600-1000mm |

600-1000mm |

|

Tranmission speed |

0~10m/min(adjustable frequency) |

0~10m/min(adjustable frequency) |

|

Dehydration Rated |

40-50KG/hour |

40-50KG/hour |

|

Contour dimension |

12500mm*1600mm*2200m (customized) |

12500mm*1600mm*2200m (customized) |

|

Width of conveyer belt |

750±100mm(customized) |

1000±100mm(customized) |

|

Microwave leakage standard |

ISO≤5mw/cm² |

ISO≤5mw/cm² |

Microwave Frozen Shrimp Thawing Machine-sample

|

Case Customer With Microwave Frozen Shrimp Thawing Machine Technology In 2021 |

|

|

1 |

Industrial Microwave Frozen Food Thawing Machine For Sale Puerto Rico |

|

2 |

High Efficiency Thawing Machine For Frozen Sea food For Sale Dominica |

|

3 |

800kg/h Industrial Microwave Frozen Seafood Thawing Machine Cost To Bolivia |

|

4 |

New Design Industrial Plc Microwave Freezing Meat Defrosting Seafood Thawing Machine For Sale For Sale In Senegal |

|

5 |

Meat Microwave Thawing Frozen Food Defrosting Machine Price In Nigeria |

|

Repurchase Case Of The Industrial Microwave Frozen seafood Thawing Machine In 2021 |

|

|

1 |

300-500kg/H Industrial Microwave Thawing Frozen Food Defrosting Machine Fruits And Vegetables For Sale Thailand |

|

2 |

50kw Uzbekistan Industrial seafood Microwave Thawing/ Defrosting Machine For Sale Uzbekistan (Tashkent) |

|

3 |

Tunnel Microwave Frozen Food Thawing Machine For Shrimp For Sale Uzbekistan |

|

4 |

50kw Microwave Mutton Thawing Unfreezing Machine For Sale With New Technology |

|

5 |

Microwave fish Trotters Meat Products Thawing Machine For Sale Zimbabwe |

|

6 |

Frozen Pork Fish Thawing Equipment Commercial Thawing Equipment For Sale Turkmenistan |