Instant noodles production line with perfect technology, compact structure, original design and stable performance, is developed on the base of like products and requirement in the world market. It realizes high automation, convenient operation, low energy and small floor space, that assures all working procedures from feeding flour to finished products can be accomplished on.

1.How Is Instant Noodles Manufactured?

Instant noodles production line with perfect technology, compact structure, original design and stable performance, is developed on the basis of advanced products and requirements in the world market. It realizes high automation, convenient operation, low energy and small floor space, which assures all working procedures from feeding flour to finished products can be accomplished once. The investment on this line is only one tenth of that larger size equipment, especially suitable to small-size or self-owned enterprises. instant noodles production line is tenacious smooth and transparent.

Instant Noodle Production Line

|

Technical Parameters Of Fried Instant Noodles Production Line 500000 Bags |

||||||

|

Model Number |

Capacity |

Power |

Steam Consumption |

Workshop For Single Layer Steamer Dimension(m) |

Workshop For 3 Layer Steamer Dimension(m) |

Workers |

|

Bfp-300 |

50000/8H |

56 Kw |

1200-1400Kg/H |

75*5*4 |

60*5*4 |

4 |

2.ABB Motor Of Fried Instant Noodles Production Line 500000 Bags

|

ABB Motor Of Fried Instant Noodles Production Line 500000 Bags |

||

|

1 |

Package Level 1 Units: |

0 carton |

|

2 |

Product Name: |

3-Phase squirrel cage motor |

|

3 |

Product Net Weight: |

5.9 kg |

|

4 |

Product Type: |

3AA2__M3AA_IE2_AA |

|

5 |

SCIP: |

27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

|

6 |

Selling Unit of Measure: |

piece |

|

7 |

Standards: |

IEC 60034-1 |

|

8 |

Starting of Motor: |

Direct Online |

3.How Are Made Fried Instant Noodles Production Line 500000 Bags In Industry?

Instant noodles made in industry by instant noodles production line

Instant noodles production line adopts samolina flour,wheat flour,potato starch,potato powder ,and corn starch as main materials, to produce a variety of noodle food in different shapes.

It is necessary to use the instant noodle production line for production. The technological process is:

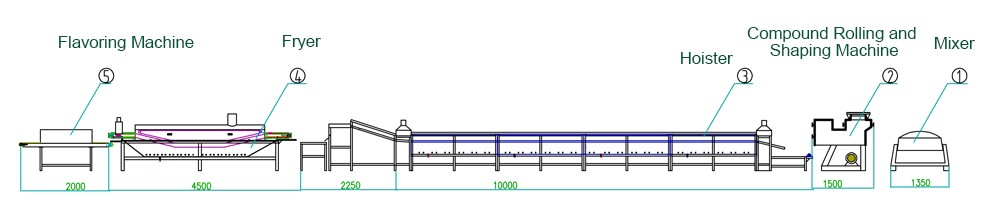

Alkaline water mixing tank------Salt water meter---Disk curing machine---Kneading machine---Roll forming machine---Steam engine---Cutting machine---Round cutting machine---Noodle Box Exchanger---Forming Machine---Fryer---Oil tank---Finishing machine---Cooler---Conveyor---Packing Machine

Processing Of The Instant Noodles Production Line

Processing Of The Instant Noodles Production Line

4.Formula Processing By Fried Instant Noodles Production Line 500000 Bags

|

Formula Processing By Fried Instant Noodles Production Line 500000 Bags |

||

|

No. |

Ingredient |

content |

|

1 |

flour |

100Kg |

|

2 |

Sodium Carboxymethyl Cellulose (CMC) |

0.3 Kg |

|

3 |

Refined salt |

1.5-2 Kg |

|

4 |

Scrape Gum (Guer Gum) |

0.2 Kg |

|

5 |

Edible alkali |

0.15—0.2 Kg |

|

6 |

Emulsifier |

0.3—0.6 Kg |

|

7 |

water |

24 Kg |

|

8 |

Nutrition supplements |

Right amount |

|

9 |

Palm oil |

20-25 Kg |

|

10 |

Seasoning liquid |

Right amount |

|

11 |

Flour brightener |

20g |

5.The Application Of Fried Instant Noodles Production Line 500000 Bags

Sample Of Instant Noodles

6.What Is The The Equipment Using In Instant Noodles Manufacturing Process?

|

What Is The The Equipment Using In Instant Noodles Manufacturing Process? |

||

|

NO. |

Instant noodles machine process |

Function of Instant noodles equiment. |

|

1 |

Feeding |

Generally, an automatic powder supply system is used, which can greatly reduce labor intensity and increase measurement accuracy. |

|

2 |

Mixing |

After the flour and starch are uniformly mixed in the flour mixer, add a certain amount of salt water, and through the mechanical stirring of the flour mixer, the gluten protein particles in the wheat flour gradually absorb water and expand and adhere to each other, forming a certain degree of elasticity, extensibility, viscosity and plasticity. At the same time, the water-insoluble starch in wheat at room temperature also absorbs water and swells, and is embedded between the gluten network to form a plastic, extensible, and cohesive wet dough. Due to the subsequent processing requirements, the amount of water cannot be added too much. At this time, the mixed dough is loose tofu-like, which can form a dough with light kneading, and can be loosened with light kneading. |

|

3 |

Proofing ingredients |

The waking effect is maturation, that is, put the loose dough after mixing into a low-speed mixing container, and improve the craftsmanship of the dough with the passage of time at room temperature. Through maturation, the moisture in the dough is more fully and evenly penetrated into the wheat flour. , so that protein and starch are fully absorbed, and the gluten network is more stable, which is the continuation of noodles. |

|

4. |

Compounding, calendering |

Compounding: The loose dough in the dough trough is fed into the sheeting roller through a feeding mechanism to form a dough sheet. The two dough sheets are combined into one dough sheet, which is called compounding. The thickness of the dough is about 5-7mm at this time. Calendering: Due to its thicker thickness, the composited noodles cannot be directly used to cut noodles, and must be thinned to be used for processing noodles. The composite back sheet is gradually reduced from thickness to thinner through the action of 5-7 on the calender rolls, forming a sheet that can be used for shredding. At this time, the thickness is generally about 1mm. |

|

5. |

Forming |

The noodle strip after the composite rolling is cut into rectangular or round thin noodles with a shredder. |

|

6. |

Steaming |

Steaming principle: The starch granules in flour absorb water, expand and rupture rapidly at a certain temperature and humidity, and their molecular structure changes from a tightly arranged β state to an α (disordered) state, which is called starch gelatinization. The steaming of noodles mainly achieves this process. |

|

7. |

Cutting off |

Dripping sauce: Pour soft water (or add a certain seasoning) on the noodles to make the noodles soft and straighten or to make the noodles slippery |

|

8. |

Fried |

Frying is to put the quantitatively cut noodles into the noodle box of the automatic frying machine to continuously pass through the high-temperature oil tank. The noodles are surrounded by high-temperature oil, and their temperature rises rapidly, and the moisture content in it quickly vaporizes. The water present in the noodles quickly escapes, forming a porous structure in the noodles, and at the same time, it further increases the degree of gelatinization of the starch in the noodles. When the noodles are soaked, hot water can easily enter these micropores. Good rehydration. On the other hand, due to the rapid drying of frying, the gelatinized state of starch after steaming is fixed, which greatly reduces the "Regeneration" Speed of the finished instant noodles in storage and transportation, and maintains the rehydration and dehydration of instant noodles. The purpose is to reduce the moisture to facilitate storage. |

|

9. |

Cooling |

The direct packaging of high-temperature noodles without cooling will generate moisture, which will cause moisture absorption and mold. Cooling will cool down the high-temperature noodles after frying. It will be cooled from about 120°c to about 5°c higher than room temperature (35°c-40°c) for subsequent packaging. Prepare. Forced refrigeration |

|

10. |

Packing |

The accessories such as the packaged noodles and the material package are sealed and packaged to prevent the noodles from absorbing moisture and deteriorate, extend the shelf life, and facilitate transportation and sales. Among them, the container noodles are packaged in a container and equipped with a fork, which can be directly brewed in the container and eaten, which is very convenient. |

7.Whats The Advantage Of New Instant Noodles Production Line?

|

New Instant Noodles Production Line Vs Traditional Instant Noodles Production Line |

||

|

|

Traditional instant noodles production line |

New instant noodles production line |

|

1 |

Same one temperature zones |

The oven has 2-5 temperature zones, which is more convenient to adjust |

|

2 |

Standard electric parts brands |

All the electric parts are using the international brands for longer life |

|

3 |

Temperature control together |

Temperature control separately |

|

4 |

No ce |

Under ce certificate, and reaching to the iso standards |

|

5 |

No warning sign |

|

8.Which Market Did The Loyal Automatic instant noodles production line Cost Sold?

LOYAL relies on complete product specifications, excellent product quality and professional service. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world

If you are interested in instant noodles machine, please contact LOYAL immediately, we will provide you with instant noodles machine, instant noodles high-quality formula,instant noodles machine technical process guidance, and instant noodles professional market analysis.

|

Cooperated Customer For Laboratory Machine Of Instant Noodles Machine |

|

|

1 |

11000pcs/8h small electric instant noodle processing line for sale singapore |

|

2 |

11000pcs/8h instant noodle production line for sale puerto rico Agent |

|

3 |

11000/8h noodles production line for sale cote d'ivoire Factory |

|

Cooperated Customer Request Engineer Installation At 2022 |

|

|

1 |

120000pcs/8 h industrial instant noodles production line for sale in uzbekistan |

|

2 |

60000/8h industrial automatic instant noodles production line for sale in senegal |

|

3 |

Mozambique 80000pcs/8h industrial instant noodles manufacturing process |

|

4 |

Bangladesh 80000pcs/8h industrial industrial instant noodles manufacturing process |

|

5 |

200000pcs/8h thai manufacturing instant noodles production line |

|

Second- Cooperation Customers Of Instant Noodles Machine At 2022 |

|

|

1 |

60000pcs/8h instant noodle line for sale dominica |

|

2 |

40000pcs/8h instant noodle line in senegal |

|

3 |

100000kg/h noodles production line in nigeria |

|

Cooperated Custome Finihsed Plant of Instant Noodles Machine At 2022 |

|

|

1 |

11000pcs/8h small raw materials for noodles production for sale botswana |

|

2 |

30000pcs/8h raw materials for noodles production for sale pakistan |

|

3 |

Small 200kg/h ingredients of instant noodles production line moldova |

|

Cooperated Agent Of Instant Noodles Machine At 2022 |

|

|

1 |

Mozambique 30000PCS/8H Industrial instant noodles manufacturing process |

|

2 |

India 80000pcs/8h Industrial Industrial instant noodles manufacturing process |

|

3 |

60000PCS/8H Thai manufacturing instant noodles Production Line |