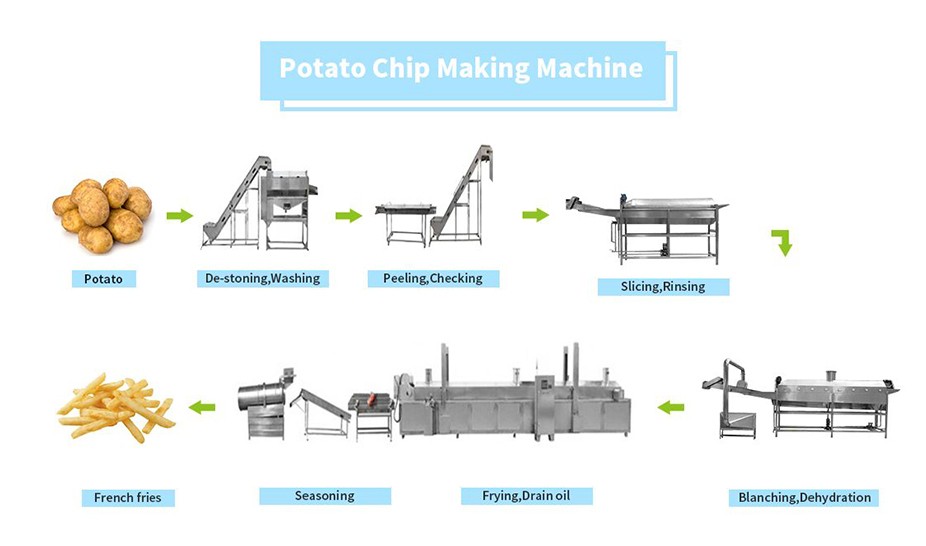

As a professional automatic potato chips production line manufacturer ,our automatic potato chips making machine project using fresh potatoes as raw materials, the whole process of washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips and Frozen french fries for sale.The potato chips processing line has the advantages of one-time investment, low energy consumption, multiple functions, small size, high profit, and convenient use and maintenance.

Automatic Potato Chips Manufacturing Processing Line

What Is The Automatic Potato Chips Plant?

The small scale potato chips manufacturing plant respectively by cleaning peeling, slicing (article), washing, blanching, rinse, dehydration, frying, deoiling, flavor,packaging, etc.Using large Shandong Loyal potato chip plant, we can provide free formulation and technical guidance. And we make sure that you fry out high quality chips with potato chips manufacturing line .If u need frozen line, plus a quick-freezing machine.

Fully automatic potato chips making machine price french fries production line potato chips maker machine is specially designed for potato chips processing into delicious potato chips, potato crisps or French fries. Apart from making potato chips and French fries, you could also make Frozen French fries (equipped with a freezer).

How To Use Potato Chips Processing Plant?

|

Production Process Of Semi Automatic Potato Chips Making Line |

|||

|

1 |

Raw Material Preparation |

2 |

Potato Chip Washing Machine |

|

3 |

Peeling Machine |

4 |

Checking Machine |

|

5 |

Potato Chip Cutting Machine |

6 |

Grading Machine |

|

7 |

Blanching Machine of Potato Chip Line |

8 |

Conditioning Machine |

|

9 |

Potato Chip Drying Machine |

10 |

Potato Chip Frying Machine |

|

11 |

Oil Draining Machine |

12 |

Potato Chip Flavoring Machine |

|

Flow chart of the automatic potato chips plant: the raw material----wash and peel----select and trim----improve the input material----slicing (strip)----rinse----Blanching and color protection ---dehydration ---- frying of potato chip plant ---- deoiling ---- seasoning ---- cooling ---- packaging |

|||

|

This set of potato chips equipment is made of 304 stainless steel, with high output and labor saving. And the potato chips processing plant is installed and debugged on site. |

|||

Full Automatic Potato Chips Production Line Flow Chart

What Is Technical Parameter Of Potato Chip Making Line?

|

Technical Parameter Of Potato Chip Making Line |

|||||

|

Model of potato chip line |

Powder |

Dimension of potato chip plant |

Weight |

Capacity |

Price |

|

LY-800 |

1.1kw/380v |

1540*730*740mm |

220kg |

100kg/h |

8500-13500USD |

|

LY-1200 |

2.2kw/380v |

2120*840*900mm |

300kg |

200kg/h |

15000-26000USD |

|

LY-1500 |

2.2kw/380v |

2400*840*900mm |

380kg |

300kg/h |

60000-110000USD |

|

LY-1800 |

3.0kw/380v |

2550*840*900mm |

400kg |

500kg/h |

120000-15000USD |

Potato Chips Continuous Frying Machine

What Is The Small Scale Potato Chips Manufacturing Plant?

The potato chips plant for sale is an advanced snack food processing equipment. The small scale potato chips manufacturing plant integrates the advantages of all kinds of individual machines. The potato chips line is easy to be operated, powerful and investment saving.

|

Main Components In The Potato Chips Manufacturing Plant |

|

|

1 |

Washing&peeling machine |

|

2 |

Picking conveyor |

|

3 |

Potato chips cutting machine |

|

4 |

Blanching machine |

|

5 |

Air cooling machine |

|

6 |

Continuous potato chips frying machine |

|

7 |

Deoiling&cooling machine |

|

8 |

Packing machine |

How About Finished Potato Chips Product Photos?

Potato Chips Samples Made By Potato Chips Making Machine

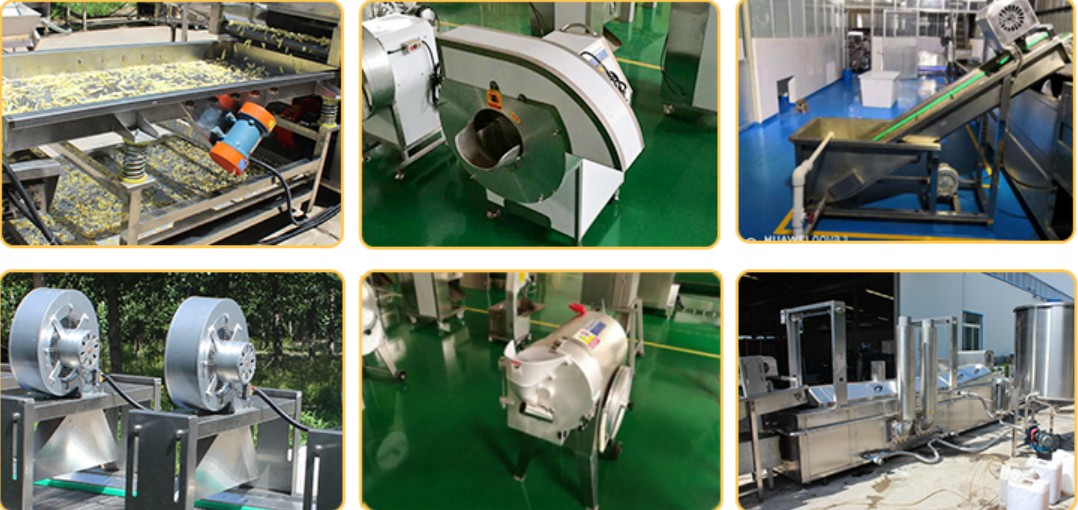

What Is Main Equipment Of Potato Chips Manufacturing Plant?

|

Main Equipment Of Potato Chips Manufacturing Plant |

||

|

1 |

Peeling Machine |

The potatoes shall be washed and peeled by the potato washing and peeling machine. |

|

2 |

Potato Chips Cutting Machine |

The peeled potatoes are cut into strips by the super-speed slicing machine of potato chips manufacturing plant price. |

|

3 |

Rinsing Machine |

Put the potato strips into the ozone disinfection vegetables washing machine and rinse out the mucus on the surface. |

|

4 |

Potato Chips Blanching Machine |

After rinsing, put the potato strips into the blanching machine of small scale potato chips manufacturing plant for inactivating the oxidase in potato strips, Preventing color deterioration and accelerating dehydration. |

|

5 |

Vibration draining Machine |

After blanching, put the potato strips into the vibration draining machine for removing the excessive moisture. |

|

6 |

Deep frying machine of potato chips plant for sale |

After dehydration, the potato strips will be conveyed into the frying machine for deep frying by the lifting conveyor. |

|

7 |

Deoiling Machine |

After deoiling processing of potato chips manufacturing plant by the air drying and lifting machine, the fried potato strips is sent to the spices mixing machine for flavoring. |

|

8 |

Seasoning Machine of potato chips manufacturing plant |

The spice mixing machine is provided with the dip type seasoning drum which can automatically control the rotate speed and capacity of materials. The small scale potato chips manufacturing plant is equipped with automatic feeding device and the feeding capacity is adjustable. It can fully mix the potato strips with the spices. |

|

9 |

Potato Chips Weighing and packing Machine |

After seasoning, the potato stripes are conveyed by lifting conveyor to the packing machine of potato chips making plant for vacuum packing or normal packing. The weighing device may be provided if it is necessary. |

Automatic Potato Chips Making Machine Details Pictures

Which Market Did The Loyal Potato Chip Production Line Sold?

|

Customer Case Of The Small Scale Potato Chips Line At 2021 |

|

|

1 |

100KG/H Thai commercial used potato chips plant for sale for Thailand customer |

|

2 |

100KG/H small scale potato chips manufacturing plant for sale in Uzbekistan |

|

3 |

200KG/H small scale potato chips manufacturing plant manufacturing machines for sale in Nigeria |

|

Customer Case Of Large Scale Potato Chips Making Machine At 2021 |

|

|

1 |

Commercial potato chips production line 100KG/H in Algerian |

|

2 |

80KG/H industrial automatic commercial potato chips line for sale in Senegal |

|

3 |

100KG/H Industrial used potato chips plant for sale sold in Russia |

|

Customer Have Factory Case Of Commercial Potato Chips Production Line At 2021 |

|

|

1 |

500KG/H automatic potato chips processing line for sale in Bolivia |

|

2 |

Mozambique 500KG/H Industrial potato chips processing line |

|

3 |

300KG/H commercial potato chips equipment for sale in Pakistan |

RFQ Of Small Scale Potato Chips Manufacturing Plant

A.What is the potato chips automatic plant cost?

Chips Plant Machinery Cost For A Small Scale Potato Chips Factory

Potato Washer & Peeler of potato chips manufacturing plant cost with low-end machine at minimum costs $500 while high-end machine costs can cost up-to $5000.

The variation in potato chips automatic plant cost is mainly due to peeling capacity per hour and due to various functions, the more peeling capacity the more potato chips manufacturing plant will cost. Potato chips manufacturing line comes in stainless steel thus you won’t be bothered by rusting.In addition, depending on the production capacity of the product, the potato chips plant machinery cost is also very different.

B.Which machines does the automatic potato chips plant mainly include?

|

Main Components In The Potato Chips Manufacturing Plant |

|

|

1 |

Washing&peeling machine |

|

2 |

Picking conveyor |

|

3 |

Potato chips cutting machine |

|

4 |

Blanching machine |

|

5 |

Air cooling machine |

|

6 |

Continuous potato chips frying machine |

|

7 |

Deoiling&cooling machine |

|

8 |

Packing machine |

C.How do you open a chip factory of potato chips manufacturing plant cost/potato chips manufacturing plant in India?

|

Potato Chips Manufacturing Plant In India |

|

|

1 |

Setting up a small potato chips factory that will target a limited region and later on will expand into the market, converting that small setup into a medium and large setup later on (in span of 3-10 years) will cost around $10K (minimum) to $40K (Maximum) potato chips plant machine price. |

|

2 |

$10Kchips plant machinery cost is the initial potato chips cost for setting up a small potato chips factory, once you want to expand, then obviously you add more and more machinery to the potato chips production line and thus the total cost will keep moving, $40K potato chips plant machine price isn't the upper limit, the potato chips machine cost is just an estimate to suggest to you that once you cross this investment threshold your potato chips factory can be counted as large factory, means you aren't anymore a small or medium factory. |

|

3 |

The above mentioned minimum $10K potato chips plant machinery cost includes only machinery; small scale potato chips machinery that you will need to utilize to make potato chips, that means you will need to calculate warehouse, vehicle, stock, inventory, raw material cost, import charges in case you want to import these potato chips making machines etc separately. |