Floating fish food production line process can produce both floating and sinking fish feed pellets. Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%.

fish food production line

Floating fish food production line by extruder technology has become a trend of aquatic fish feed processing technology. The function of extruder machine is to change the weight of feed, to make floating, slow-sinking and sinking extruded fish feed. extruder machine manufacturer use fish feed extruder machine produce floating fish feed, sinking fish feed etc.

Feed extruder manufacturers to develop technology and recipes for aquaculture. The products can have different shapes with fish pellet production line, unique flavor, rich Make fish feed for different fishs, such as trout, turbot, cod, halibut, yellow tail, sea bass, sea bream, tilapia , aquarium fishes, gold fish, shrimp, prawn etc .fish food extruder machine are designed to produce feed that meets the nutritional requirements of fish and other aquatic animals, with precise size and density control, whilst respecting the highest standards of water quality .

Whats The Fish Feed Processing Line Cost?

|

Price Of Fish Feed Processing Line |

||||

|

Fish Production Line Model |

Fish Production Line Capacity |

Fish Production Line Cost(Usd) |

Fish Production Line Size (L*W*H) |

|

|

LY-1 |

100-150KG/H |

20,000-32,000 |

22500X1200X2200MM |

|

|

LY-2 |

200-250KG/H |

35,000-40,000 |

25000X1500X2200MM |

|

|

LY-3 |

300-350KG/H |

45,000-53,000 |

30000X3500X4300MM |

|

|

LY-4 |

400-500KG/H |

56,000-64,000 |

40000X2400X4000MM |

|

|

LY-5 |

800-1000KG/H |

80,000-92,000 |

24000*2000*2800MM |

|

What Is The Layout Dimensions Of Floating Fish Feed Production Line?

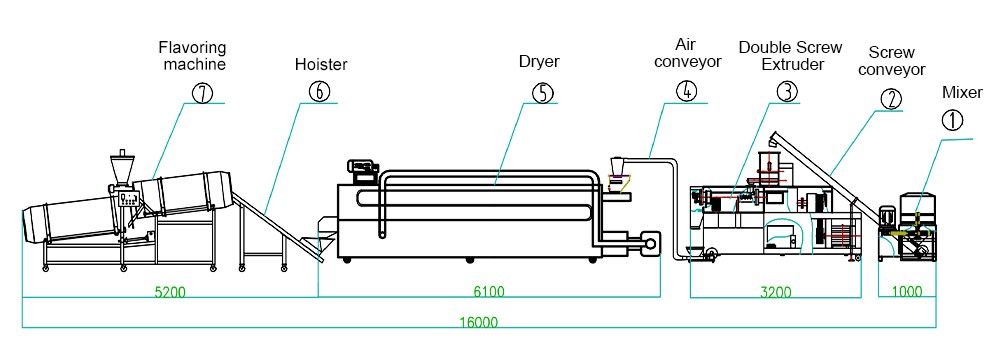

Mixer-Screw Conveyor-Doble Screw Extruder-Air Conbeyor-Dryer-Hoister-Flavoring Machine-Cooling Machine

Flow chart of Fish production line

What is the Advantages Of Twin-Screw Extruders For Feed Pellet Production Line?

1. Ingredient flexibility for different raw materials

2. Mixing well and can get excellent protein matrix,through the pre treatment of the fodder, it can reduce loss of nutrition and advance the protein ratio. So the fodder will be digested easily by fish.

3. Control of process parameters to get floating or sinking fishes pellet

4. feed pellet dimensions calibrated from 0.5 to 30.0 mm

5. Output range, from 100 to 2,000 kg/h

6.It adopts corn flour, wheat flour,low temperature soya flakes meal, rice bran, wheat bran as raw materials.

7. high output, low consumption is realized by the steam and electric design. High temperature and high pressure can kill the salmonellosis and bacterial infections.

8.We can adjust the cutter of floating fish feed pellet mill to get different diameter and the length.

Machine detail of fish feed production line

What Equipment Is Needed For Floating Fish Feed Production Line?

| Equipment For Floating Fish Feed Production Linematerials Of Fish Feed | ||

|

1 |

Receiving, cleaning and coarse crushing of raw materials |

Raw materials can be roughly divided into two categories, powder and pellets. The former does not need to be coarsely crushed. For this kind of raw materials, it can be directly passed through the lowering pit and hoist, then enter the preliminary cleaning screen for impurity removal, and then undergo magnetic separation, and directly enter the batching bin through the distributor or screw auger to participate in the first time. Ingredients; the latter needs to be coarsely pulverized. The materials enter the cleaning equipment through the lowering pit and hoist, and then enter the warehouse to be crushed. After coarse pulverization, the materials enter the batching warehouse through the hoist and distributor. Ingredients for the first time. |

|

2 |

Ingredients and mixing at one time |

The first batch of ingredients is mainly the preparation of popular raw materials, that is, the preparation of relatively large materials in the formula. |

|

3 |

Secondary crushing |

After being lifted, the mixed material enters the smashing bin, and then enters the secondary crusher. After the secondary crushing process is completed, it enters the rotating grading screen to remove the fine fluff formed by the coarse fiber in the feed during the crushing process.。 |

|

4 |

Secondary mixing |

During the primary mixing of the feed, only some common feeds such as corn, cotton meal, rice bran meal and other materials are mixed, and each raw material enters the secondary mixer (Figure 2-6) after the secondary ingredients. There is an artificial feeding port above the mixer, which is specially used for adding trace additives (such as sodium bicarbonate, table salt, calcium bicarbonate, etc.). |

|

5 |

Modulation and puffing |

In the granulation process, the material rotates at high speed inside the machine as a powder. At the same time, a pipe sprays steam-like water into the machine bin to make the material condense quickly. In the high-speed rotating bin, the granulator ring Extrude from the small holes on the mold (Figure 2-8) to form pellets, which will gradually cool and harden as they fall. After the above-mentioned processing, most of the feed contains a lot of small hard fibers. For aquatic animals with a less developed digestive system, it is difficult to completely absorb and utilize it. This will easily lead to waste of feed, so it is often necessary to do the final puffing. deal with. In the extrusion process, the material is cooked for a period of time under high temperature, high humidity, and high pressure. During the process, the cooking properties of the material change drastically (mainly starch gelatinization, protein denaturation), and the material is extruded from the mold hole The pressure drops suddenly, and the water in the feed is transformed from liquid to gas, and emitted from the feed to cause the material to expand, forming the so-called extruded feed. |

|

6 |

Drying, spraying and cooling Of fish food processing line |

After the material is extruded by the extruder, it will form squishy particles (moisture content between 25% and 30%). In order to reduce the fragmentation of the particles, it is advisable to adopt pneumatic conveying, and then discharge from the extruder and enter the dryer through the flow tube for drying. The moisture content of the material drops to about 13%. After the material is dried, it can enter the external spraying system. Use the air pressure of the air compressor to spray grease, sweeteners and other additives on the surface of the feed when the material falls from the buffer bin. At the same time, the control valve controls the falling speed of the material and the spraying speed of the sprayer, so that the grease can be evenly sprayed on the surface of the feed. Then it can be cooled. The drying, spraying and cooling of the feed are a continuous step. |

|

7 |

Product classification and packaging |

The cooled materials are lifted and crushed into the grading screen for classification. The crushed materials often have some particles of different sizes, some of which are smaller particles, and some are intact particles, as well as broken particles and powder. They will be sent to the rotating grading screen together by the elevator. The encapsulation of the finished product is carried out on the sewing machine uniformly used by a dedicated worker to receive the material and seal the package. |

What Are The Main Ingredients In Fish Food?

| Main Ingredients Of Fish Food | ||||

|

1.(Feed coefficient is 1.9, plus green fodder.) |

||||

|

Rice bran 40% |

Bran 38% |

Bean Cake 10% |

Fish meal 10% |

Yeast powder 2% |

|

2.(The feed coefficient is 4.90, plus green fodder.) |

||||

|

Bean Cake 10% |

Straw powder 80% |

|

|

|

|

3.(The additives are (based on the total basal diet): 12% sweet potato flour, 0.50% salt, 2% auxin, and 2% calcium hydrogen phosphate.) |

||||

|

Corn flour 70% |

Bran 5% |

Fish meal 10% |

Bean cake flour 15% |

|

|

4.(Add according to the total basal diet: sweet potato flour 12%, salt 0.50%, auxin 2%, calcium hydrogen phosphate 2%.) |

||||

|

Sweet potato vine powder 80% |

Bean cake flour 15% |

Bran 5% |

|

|

fish feed production line

Regarding the fish feed production line, customers usually encounter problems:

Q: How is the pet feed made?

A: Our production line mainly uses meat meal, fish meal, bone meal, soybean meal, etc., as the raw materials for producing pet feed. These raw materials are crushed and prepared, mixed and conveyed, extruded and puffed, dried, sprayed and flavored, cooled and packed, and finally formed into the final pet feed.

Q: What equipment is needed for fish feed production?

A: Usually need: Mixer, screw conveyor, twin screw extruder, air conveyor, oven, seasoning oil injection system, cooling machine, packing machine.

Q:How to build a fish feed factory?

A:First, you need to build a factory, and then choose the right output according to your own budget. At the same time, Our technicians can provide you with appropriate length, width, and height CAD drawings to help you design your factory. Suppose you want to reserve a site for workers' activities. In that case, you can inform our salesman. We will make the appropriate designation of your program according to the specific needs so that the site is more suitable, not to waste every bit of space, and use the site reasonably to prevent the machine more smoothly.

Which Market Did The Loyal Fish Feed Production Line Sold?

|

Customer Case Of Fish Feed Production Line At 2021 |

|

Lyfish-5 Floating Fish Food Making Machine For Sale Pakistan |

|

Small 200kg/h Floating Fish Feed Production Line Moldova |

|

100-150kg/h Floating Fish Feed Plant Foe Sale Ukraine Factory |

|

LYFISH-50 small electric fish food making machine for sale Singapore |

|

1T/H Fish Feed Machine For Sale Puerto Rico |

|

2T/H floating fish feed extruder machine for sale Bolivia |

|

500KG/H Fish Food Making Machine For Sale Dominica |

|

1T/Hfeed pellet production line in Senegal |

|

150KG/H Small Floating Fish Feed Mill Plant In Nigeria |

|

1T/H Fish feed pellet production line For Sale Cote d'Ivoire |

|

Customer Case Of Fish Feed Production Line At 2020 |

|

Small electric fish food making machine for sale Lebanon |

|

500-600kg/h fish food making machine for sale UAE |

|

LYFISH-50 Small Fish Food Making Machine For Sale Tashkent |

|

1T/H floating fish feed plant for sale Uzbekistan(Gizak) |

|

China 30000 Tons Per Year Feed Mill For Fish And Pet Feed Pellets |

|

15T/H Aqua Feed Plant For Fish Prawns Crab Feed Production In China |

|

Simple Design Small Fish Feed Pellet Line For Sale UK |

|

Floating fish feed production line for sale Lithuania |

|

Wet fish feed making machine DSP-120B for sale Russia |

|

1T/H sinking fish feed plant Thailand |

|

Uzbekistan 1T/H Floating Fish Feed Plant For Sale Uzbekistan (Tashkent) |

|

Customer Case Of Fish Feed Production Line At 2020 |

|

200-250KG/H floating fish feed plant for sale Zimbabwe |

|

LYFISH floating fish food making machine for sale Turkmenistan |

|

LYFISH-3 floating fish food making machine for sale Honduras |

|

Simple Design 2T/H Fish Feed Production Plant For Sale Bolivia |

|

Fish Food Production Line manufacturers & suppliers |

|

150kg/h Small fish feed processing line For Sale Tanzania |