The cheetos making machine is another type of small food production line after the puffed food production line. It uses corn starch and potato starch as the main raw materials and uses the extrusion molding process to achieve the sensory effect of the product shape. The cheetos shape is natural and realistic, and the texture is delicate. The taste is loose, not cracked or scattered. The production line has a good design, strong stability, and a high degree of automation. The host adopts frequency conversion speed regulation technology to ensure the stable quality of processed products. It is a combination of traditional technology and modern technology. The products include spirals, potato chips, shrimp cracks, shells, round tubes, Dozens of kinds of snails, circles, waves, foams, etc., are available.

cheetos making machine

WHATS THE PROCESS OF CHEETOS MAKING MACHINE?

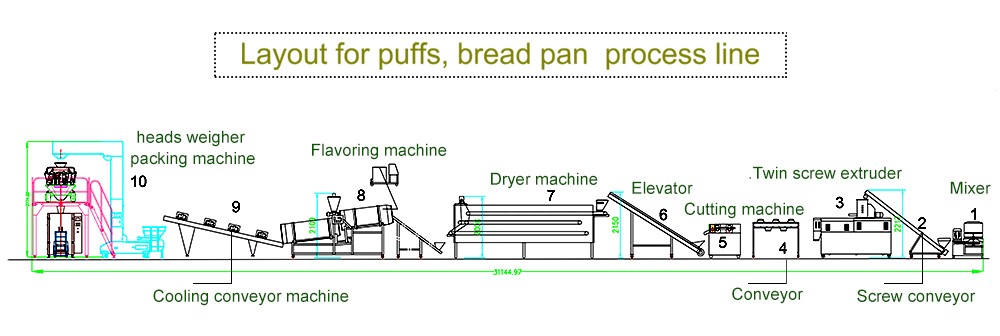

Mixer → screw conveyor → screw extruder → shaping machine → elevator → dryer → flavoring machine →cooling machine → packaging machine

Puffed snacks are usually mixed with a small amount of water into the starchy raw materials, and the raw materials are continuously pressurized and heated with an extruder to expand the raw materials quickly and then appropriately cut and seasoned as needed.

The seasoning method of puffed snacks is generally to spray seasoned vegetable oil, spray vegetable oil, sprinkle with seasoning liquid, and then dry. There are also puffed snacks, which are first dipped in vegetable oil, and then sprinkled directly with seasonings.

However, the puffed snacks made by the above-mentioned various seasoning methods have disadvantages such as not being crisp enough, sticking to the teeth, and falling off the seasoning.

In the cheetos making machine production process, puffed snacks sprayed with vegetable oil can be immersed in the bran and dried into a crispy finished product to solve the above shortcomings. Because the condiment penetrates the food, puffing the snack. It has an excellent chewing taste, good flavor, luster, uniform color, and a beautiful appearance.

Cheetos products

The cheeto extruder has two pairs of screws that mesh with each other and rotate in the same direction, which together play the role of conveying frictional extrusion, and heating, relying on the principle of positive displacement to input materials for forced giving, and seldom form pressure Reflux, to better solve this problem on the single-screw extruder, and powerfully convey. The extruder integrates multiple functions such as compression, mixing, kneading, shearing, melting, sterilization, expansion, and molding and can be completed in a very short time. The change of the mold can change the shape and size of the product. The twin-screw extruder can produce a wide variety of foods on the production line and can produce snack foods, breakfast cereals, core filing puffed foods, and countless puffed foods can be developed.

Cheetos samples

WHAT IS THE RECIPE FOR CHEETOS PUFFS ?

|

Cheetos Puffs Ingredients |

|

|

Ordinary puffing snacks |

|

|

Ingredient |

Proportion |

|

Rice flour: |

50% |

|

Corn flour: |

30% |

|

Flour: |

20% |

|

French chalk: |

0.2% |

|

Water: |

2~3% |

|

Candied element: |

0.2%(water-solubility) |

|

Jam Center Material ingredients(Chocolate Taste): |

|

|

chocolate plate : |

70% |

|

Cacao grease : |

20% |

|

Sugar powder: |

1% |

|

Jam Center Material ingredients(Peanut Taste): |

|

|

Palm oil: |

30% |

|

Sugar powder: |

30% |

|

Peanut butter: |

40% |

WHAT ARE FEATURES OF CHEETOS MAKING MACHINE?

|

Features Of Cheetos Making Machine |

|

|

1 |

The design is reasonable, the structure is compact, and the operation is effortless. |

|

2 |

The operation is highly automated. Only one or two people can complete the processing process, saving manpower. |

|

3 |

Stable performance and reliable quality. It is carefully researched and developed by a professional team to meet the needs of food processing. |

|

4 |

Low cost, high efficiency, low energy consumption to ensure the whole process from feed to finished product. |

|

5 |

The machine's output can be changed by configuring more extruders on one production line to meet higher output requirements. |

|

6 |

Cheetos making machine are made of stainless steel, and the screws are made of alloy steel, with a modular system structure and self-cleaning function |

CHEETO EXTRUDER TWIN-SCREW EXTRUSION PROCESSING VERSUS CONVENTIONAL FOOD PROCESSING

|

Cheeto Twin-screw Extrusion Processing Vs Conventional Food Processing |

||

|

Sustainable |

Remarkable process-intensifying capability of twin-screw extrusion technology and cheetos making machine allows determinant operational advantages to be achieved, such as: continuous HTST (High Temperature-Short Time) cooking, high productivity owing to reduced downtime and material losses, energy and water savings, reduced footprint. |

The degree of automation is low. High energy consumption |

|

Highly flexible |

the same processing line is able to process various types of raw materials and mix formulations, and to produce a wide range of end products |

whereas conventional cereal cooking processes (baking, hydrothermal cooking, etc.) are often limited to the production of low ranges of end-products with restricted possibilities to change operating parameters. |

|

Fully automated |

with high level of operating stability; hence leading to consistent product quality |

whereas conventional processing lines require frequent adjustment of process parameters. |

PRICE OF CHEETOS SNACK PRODUCTION LINE

As a cheetos making machine factory, to adopt the small scale cheetos machine is a good choise ,here was the price of cheetos making machine for your refer----

|

|

OUTPUT OF CHEETOS MAKING MACHINE |

PRICE OF CHEETOS MAKING MACHINE |

|

1 |

100-150KG PER HOUR |

12,000 USD-20,500USD |

|

2 |

200-250KG PER HOUR |

20,500 USD-30,500 USD |

|

3 |

300-350KG PER HOUR |

30,500 USD-40,500 USD |

WHICH MARKET DID THE LOYAL CHEETOS SNACK PRODUCTION LINE SOLD?

The share of LOYAL's export cheese puff chips machine in the international market has steadily increased. According to the export goods trade data of snack production line in 2021. Loyal's export market share in the international market is 86.5%, of which the export market share of puffed snacks in Africa is 20.8%. The market share of puffed snacks exported to the Americas was 30.2%. The export market share of puffed snacks in Asia is 35.5%. If you are interested in puffed snacks, please contact us today and we will provide you with the most cost-effective turnkey solution.

|

Repurchase Cheetos Making Machine Customer At 2021 |

|

|

1 |

Bangladesh 2t/h Industrial Snack Food Production Line |

|

2 |

Algerian Cheese puff Chips 300kg/h Production Line |

|

3 |

Sudan 200kg/h Cheese Puff Chips Machine |

|

Customers With Cheetos Making Machine Factory At 2021 |

|

|

1 |

1t/h Thai Snack Food Production Line |

|

2 |

1000kg/h Industrial Automatic Snack Food Production Line For Sale In Senegal |

|

3 |

Moldova Small 200kg/h Cheese Puff Chips Machine |

|

High Quality And High Quality Producer Of Cheetos Making Machine At 2021 |

|

|

1 |

China 300t/Year Industrial Automatic Cheese Puff Snack Production Line |

|

2 |

Cheese Puff Chips Machine For Sale In Pakistan 100kg/h |

|

3 |

Nigeria 150Kg/H Cheese Puff Chips Machine |

|

Customers Who Understand Cheetos Making Machine At 2021 |

|

|

1 |

200kg/h Cheese Puff Chips Machine Sold In Ukraine |

|

2 |

Nigeria 150Kg/H Cheese Puff Chips Machine |

|

3 |

Austria Sells Cheese Puff Chips Machine 100kg/h |

Cheetos snacks produce video