The automatic cheese puff snack production line is a new type of puffed snack production equipment that is different from the traditional process. The snack manufacturing equipment uses corn husks as raw materials, squeezed and expanded in an extruder, fried in a deep fryer, filtered out the excess oil in an oil filter, and seasoned in a seasoning tank. The length of the strap is adjustable and can be made into a variety of flavors, including strawberry, matcha, and chocolate. It tastes crispy and crunchy. The more it tastes, the more fragrant it tastes, and it's not greasy at all.

cheese puff snack production line

HOW ARE CHEESE PUFFS MADE?

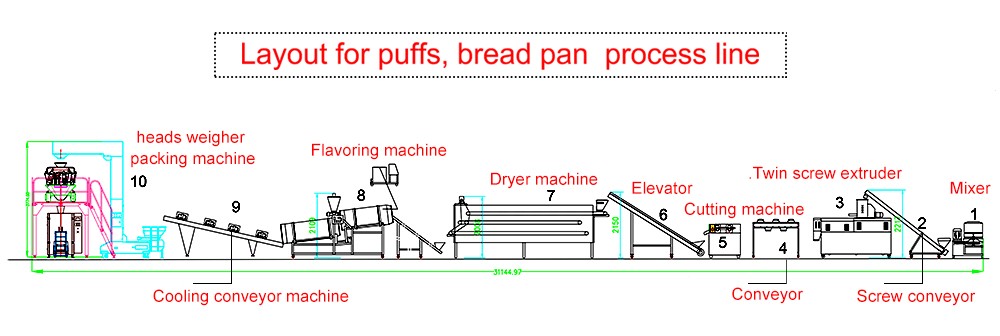

Layout for cheese puff snack production line

Mixer → screw conveyor → screw extruder → shaping machine → elevator → dryer → flavoring machine →cooling machine → packaging machine

Once they are prepared, controlled quantities of raw materials and process liquids are premixed and then dosed to feed the extrusion platform continuously and consistently. The homogeneous mix thus created by the action of two co-rotating screws is subjected to thermo-mechanical processing to gelatinize the starch and cook the product. The paste is then pushed through the die to shape, expand and give the product its light and airy finished texture. The design of the die insert, the moisture content in the extruder and the expansion ratio are key factors in determining the texturing and shaping of expanded snack products.

At the extruder exit, the expanded product is either cut directly at the die head or conveyed on a belt to be cut by a post extrusion cutting system. The product can also be filled (injection of the filling at the level of the die) when the unit is equipped with a co-extrusion module.

Shaped snacks are transported on a belt dryer at a controlled temperature to achieve the target level of moisture content. The dried product is then cooled for storage or directly conveyed to the coating system. Two types of coating are used: an oil/flavour mixture to produce a slurry to be applied directly to the snack or, alternatively, an oil spray and dusting with flavour, spices, salt and other powdered materials. The flavored snacks are then cooled to room temperature before being transported to the packaging units.

WHAT SNACKS CAN THE AUTOMATIC CHEESE PUFF SNACK PRODUCTION LINE PRODUCE?

|

Puff Snacks Produced By Automatic Cheese Puff Snack Production Line |

|

|

Puffed snacks |

Direct expanded snacks, indirect expanded snack pellets, coextruded products, cereal chips and crackers, extruded croutons and bread snacks, etc. |

|

Raw material diversity |

Cereals (corn, wheat, oat, barley, rice …), whole grains and / or mixtures of grains, ancient grains (amaranth, quinoa, etc.), tubers and roots, etc. |

|

New features |

Such as innovative shapes and textures, various coatings and fillings (sugar and savoury) Nutritional products rich in fiber, vitamins and minerals. |

ARE CHEESE PUFFS HEALTHY?

In the eyes of most people, puffed food is unhealthy junk food. They think it is the representative food of high oil and high salt. Puffing is just a food processing method. Sugar, salt, and additives generally do not cause any harm to the body. On the contrary, they provide some nutrients.

So, is puffed food good for us? Healthy puffed food does have certain benefits. For example, for people with poor gastrointestinal function, the puffing method can quickly gelatinize the starch in the grain, improve the hydration rate of protein and carbohydrates, and increase a large amount of water solubility. The substance helps digestion.

Although puffed snacks are delicious, there are still some aspects to pay attention to when eating. You can occasionally use puffed food as a snack. Do not eat a lot, and do not eat before meals or before going to bed. Otherwise, it will quickly lead to obesity or other things. In terms of the problem, especially eating puffed food at night, high-fat food stays in the stomach for a long time, affecting digestive function and night sleep.

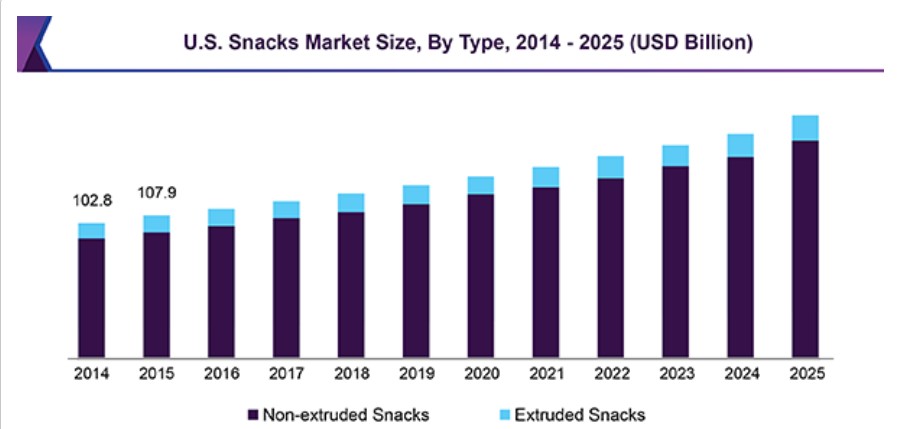

WHAT IS THE SNACK FOOD INDUSTRY WORTH?

The global snack food market was worth USD 439.9 billion in 2018 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2019 to 2025. Increasing health issues and changes in lifestyle and diet have stimulated the demand for various snack options on a global scale. More and more snacks instead of meals, and more and more people request allergen-free vegan products, is a key trend to promote the development of the market. International brands have been taking advantage of this opportunity to pack their products in a more convenient way to extend the shelf life and make it easier to consume on the go. Innovative concepts, flexible products that meet consumer needs, and a busy lifestyle will benefit the market growth.

Market of cheese puff snack production line

ABB MOTOR OF AUTOMATIC CHEESE PUFF SNACK PRODUCTION LINE

|

Motor Parameters |

||

|

1 |

Package Level 1 Units: |

0 carton |

|

2 |

Product Name: |

3-Phase squirrel cage motor |

|

3 |

Product Net Weight: |

5.9 kg |

|

4 |

Product Type: |

3AA2__M3AA_IE2_AA |

|

5 |

SCIP: |

27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

|

6 |

Selling Unit of Measure: |

piece |

|

7 |

Standards: |

IEC 60034-1 |

|

8 |

Starting of Motor: |

Direct Online |

Details of cheese puff snack production line

HOW MUCH DOES AUTOMATIC CHEESE PUFF SNACK PRODUCTION LINE COST?

|

Machines Price For Automatic Cheese Puff Snack Production Line |

|||

|

Automatic Automatic Cheese Puff Snack Production Line Model |

LY65 |

LY70 |

LY80 |

|

Whole Line Weight(kg) |

3000 |

4000 |

5000 |

|

Puff Snacks Process Line Price |

US$22,000.00 |

US$36,000.00 |

US$43,000.00 |

|

Capacity(kg/h) |

100-150 |

150-250 |

250-350 |

|

Total Power(kw) Electric Drying Type |

90kw |

110kw |

150kw |

|

This Is Our Updated List Of Puff Snack Machines In Stock In 2022 If You Need To Verify Or Update Contact Us. |

|||

WHICH MARKET DID THE LOYAL AUTOMATIC CHEESE PUFF SNACK PRODUCTION LINE COST SOLD?

LOYAL relies on complete product specifications, excellent product quality and professional service. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world

If you are interested in cheese puff chips machine, please contact LOYAL immediately, we will provide you with cheese puff chips machine, cheese puff chips high-quality formula, cheese puff chips machine technical process guidance, and puff snacks professional market analysis.

|

Repurchase Cheese Puff Chips Machine Customer At 2021 |

|

|

1 |

USA 1T/H Cheese Puff Chips Machine |

|

2 |

Cheese Puff Chips Machine For Sale In Pakistan 100kg/h |

|

3 |

Nigeria 150kg/h Cheese Puff Chips Machine |

|

Customers With Snack Food Production Line Factory At 2021 |

|

|

1 |

1t/h Industrial Snack Food Production Line For Sale In Uzbekistan |

|

2 |

1000kg/h Industrial Automatic Snack Food Production Line For Sale In Senegal |

|

3 |

Mozambique 1t/h Industrial Automatic Cheese Puff Snack |

|

High Quality And High Quality Producer Of Automatic Cheese Puff Snack Production Line At 2021 |

|

|

1 |

China 300t/year Industrial Automatic Cheese Puff Snack Production Line |

|

2 |

1t/h Tough Snack Food Production Line For Sale In Puerto Rico |

|

3 |

1t/h Crisp Snack Food Production Line For Sale In Bolivia |

|

Customers Who Understand The Snack Food Production Process At 2021 |

|

|

1 |

Senegal 1t/h Industrial Snack Food Production Line |

|

2 |

1t/h Snack Food Production Line For Sale In Côte D'ivoire |

|

3 |

1t/h Industrial Snack Food Production Line Sold In Russia |

Working video of cheese puff snack production line