Corn flakes production line,Corn flakes / Breakfast cereal is one kind of crispy food, with the advantages of hard to be steeped broken and strong grain taste. It is the crispy flake which is made from cornmeal and the other grains powder. The production line includes mixing, extruding, flaking, drying, high-temperature baking, flavoring, and cooling. It can be eaten like a snack, and be eaten with milk or coffee as well. By changing the models and production process, this production line can make different shapes of puffed food. Such as ring,ball,flake,star,letter etc.

Brief Introduction Of Kellogg's Manufacturing Process

Breakfast Cereal Corn Flakes Production. Corn Flakes Manufacturing Business. Breakfast Cereal Food Production Plant. Corn Flakes from Maize.

Corn flakes are healthy and nutritious food. The food is popular in the both developed and developing countries. Apart from popcorns, this is one of the most popular commercial items you can produce from maize. Additionally, it is a very popular food for breakfast. Generally, people take this food with warm milk. It is a very quick meal and acts as the appetiser also.

Maize provides invaluable nutrients substances. Additionally, these nutrients are very necessary for the balance of human diet. The various substances are proteins, carbohydrates, starch, fat and water. Apart from the normal corn flakes, there some other varieties are also available in the market. And these items offer different tastes and flavours. Such as corn flakes with honey or almonds or nuts etc.

How corn flakes are manufactured?

Let’s learn the Kellogg's corn flakes manufacturing process corn flakes processing steps

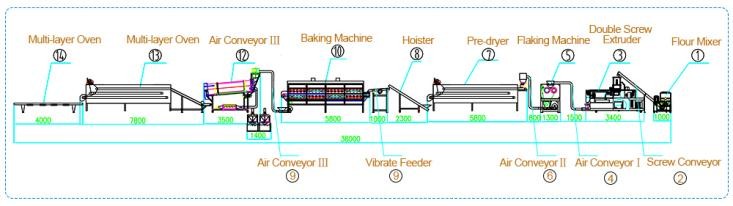

Flour Mixer → Screw Elevator → Double-screw Extruder → Air Convveyor → Flaking Machine → Elevator → Dryer → Elevator → Roaster → Elevator → Coating Line → Vibrating Spreader → Elevator → Dryer → Cooling Conveyor

cereal processing technology

Craft of kelloggs cereal manufacturing equipment cereal production equipment

Corn flakes is a breakfast cereal products made by mixing corn with minerals and vitamins to make them as healthy using maize starchy and corn grits raw materials.

The corn flake is mainly breakfast food in many countries. It is make by baked flakes of maize. The breakfast cereal corn flake is popular all over the worlds now. Here Avan machinery supply the extruison machine line on producing of breakfast cereal corn flakes. The corn power and other nutrition power are mixed together with waters. The double screw extrusion machine could produce the corn pellets balls with half cooked. The flake press machine could make flakes from pellets ball. After roasting, sugar sprayer and drying. The corn flake is ready to east.

This cereal processing equipment can not only produce the corn flakes but also breakfast cereal products by adjusting some assistant machines.

|

Technologies and equipment involved in breakfast cereal production and processing |

|

|

Mixer machine |

This machine is mainly used to mix all materials together with water. And make materials ready to cook. |

|

Conveyor machine. |

The conveyor machine is a transport equipment, which left mixed materials into twin screw extrusion machine hopper |

|

Twin screw extrusion machine. |

The extrusion machine could produce the pellets ball of flakes. The pellets ball is half cooked, and not puff ball. |

|

Vibrate cooling conveyor. |

This machine's function is cool the pellets ball and stop them stick together. |

|

Conveyor machine. |

The conveyor machine is a transport equipment, which left mixed materials into twin screw extrusion machine hopper. |

|

Flake press machine |

The corn flake press machine is mainly used to get flake from pellets ball. There are two big rollers to press pellets materials. |

|

First dryer oven. |

First dryer oven. |

|

The baking machine. |

Baking machine could full cook the flakes. It could be gas, electricity energy. |

|

The sugar sprayer machine system. |

Including the sugar sprayer drum, sprayer tanks.

|

|

Second drying machine. |

Second drying machine.cereal production equipment |

|

Cooling machine |

|

|

Packing machine. |

Packing machine. |

Features of cereal manufacturing equipment

The main raw material is corn powder in 60-80 mesh, and other grain powder or some nutritional ingedients, like vitamin. The raw materials will be cooked well in the extruder by twin screw rotating under high temperature and pressure. After the high temperature roaster, the flakes will be bublled and smelt well.

The coating line of cereal processing equipment can make the syrup or honey on the flakes surface.

This corn flakes processing line is characteristics of simple opeation, reasonable structure, low consumption, and high efficiency, which make it the best choice for medium factory.

cereal processing technology

Parameter Of Kelloggs Cereal Manufacturing Equipment

|

Technologies and Equipment in Cereal Processing and Production |

||||

|

Model |

LY65 |

LY70 |

LY85 |

Price |

|

Installed Power |

130kw |

160kw |

190kw |

20000USD |

|

Power Consumption |

90kw |

120kw |

140kw |

25000USD |

|

Production Capacity |

100-150kg/h |

200-260kg/h |

300-500kg/h |

30000USD |

|

Dimension |

39000*1300*2500mm |

41000*1500*2500mm |

43000*3500*4300mm |

32000USD |

|

The price of the kelloggs cereal manufacturing equipment is a promotional price in 2022, update price. Check with our corn flakes production line team. |

||||

Advantage Of Kelloggs Cereal Manufacturing Equipment

1. The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

3. The forced lubrication system can guarantee the equipment transmission life longer.

4. The auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

5. Self-cleaning, when stopping, it can be cleaned without disassembling.

6. We provide cereal processing technology

(cereal processing technology pdf)

What cereal is made by Kellogg's?

|

Recipe of breakfast cereal manufacturing process |

|

|

Taste |

Ingredients |

|

Icing oatmeal |

Degerminated yellow corn flour, white sugar, salt, maltodextrin, vitamin C, iron, vitamin A, niacin, vitamin B1, vitamin B6, vitamin B2, vitamin D, folic acid, vitamin B12. |

|

Honey Nut Oatmeal Rings |

Whole grain oat flour, white sugar, modified corn starch, wheat germ, brown sugar, honey, oat fiber, salt, calcium carbonate, trimethyl phosphate, almonds, vitamin C, vegetable oil, reduced iron, vitamin A, nicotinamide, zinc oxide , Food flavor, vitamin B6, annatto, caramel color, vitamin B2, vitamin D, vitamin B1, folic acid, vitamin B12.cereal processing technology |

|

Fruit Flavored Cereal Oatmeal |

Whole grain corn, white sugar, whole grain oats, corn syrup, vegetable oil, concentrated pear puree, edible salt, annatto, rice bran, corn bran, trisodium phosphate, flavoring, sodium citrate, citric acid, vitamin E, ascorbic acid. Vitamins and minerals: calcium, vitamin C, zinc, iron, niacin, vitamin B6, vitamin B2, vitamin B1, vitamin A, folic acid, vitamin B12, vitamin D. |

|

Technologies and Equipment Involved in Breakfast Cereal Production and Processing |

|

Market analysis Of Kellogg's Manufacturing Process

corn flake manufacturers are adopting various market strategies, including product launch, merger & acquisition, and expansion of distribution channels, in order to capture the greater market share and expand the customer base across the globe. For instance, in May 2018, Nestlé S.A. announced a joint venture with General Mills to sell a wide variety of products in India. Nestlé S.A. has a large number of products in breakfast cereals, such as corn flakes, KoKo Krunch, and Honey Star. These market strategies are expected to have a positive impact on the industry growth over the forecast period.

|

Report scope of breakfast cereal manufacturing process |

|

|

Attribute |

Details |

|

Base year for estimation |

2019 |

|

Actual estimates/Historical data |

2016 - 2018 |

|

Forecast period |

2020 - 2027 |

|

Market representation |

Revenue in USD Million & CAGR from 2020 to 2027 |

|

Regional scope |

North America, Europe, Asia Pacific, Central & South America, and Middle East & Africa |

|

Report coverage |

U.S., U.K., Germany, France, China, India, and Brazil |

|

Country Scope |

Revenue forecast, company share, competitive landscape, growth factors and trends |

|

15% free customization scope (equivalent to 5 analyst working days) |

If you need specific information, which is not currently within the scope of the report, we will provide it to you as a part of customization |

Customer Cases for Corn Flakes Processing Machine in 2021The international market share of Shandong Loyal Industrial's exports has steadily increased. According to the export goods trade data in 2021, Loyal's international export market share is 86.5%, of which the breakfast corn flakes production line and the breakfast cereal production line's export market share in Africa will have a market share of 20.8%, and the breakfast corn flakes production line and the breakfast cereal production line's export market share in the Americas will have a market share of 30.2%.

Breakfast corn flakes production line The breakfast cereal production line export market share in Asia is 35.5%, if you are interested in the breakfast corn flakes production line, please contact us immediately, we will provide you with the most cost-effective turnkey solution

|

Cooperated Customer Request Engineer Installation At 2021 |

|

|

1 |

China 300t/year industrial corn flakes manufacturing machine |

|

2 |

1T/H Corn Flakes Processing Machine for sale in Puerto Rico |

|

3 |

1T/H Corn Flakes Processing Machine for sale in Bolivia |

|

4 |

Senegal 1T/H corn flakes processing steps corn flakes Production Line |

|

5 |

1T/H Corn Flakes Processing Machine for sale in Côte d'Ivoire |

|

Cooperated Customer with Corn Flakes Processing Machine Technology At 2021 |

|

|

6 |

1T/H Corn Flakes Processing Machine sold in Russia |

|

7 |

1T/H Corn Flakes Processing Machine for sale in Uzbekistan |

|

8 |

1000kg/h industrial automatic corn flakes machine for sale in Senegal |

|

9 |

Mozambique 1T/H corn flakes manufacturing process |

|

10 |

Bangladesh 2t/h Industrial corn flakes making process |

|

11 |

1T/H Thai corn flakes processing line |

|

12 |

Uzbekistan 1T/H corn flakes production |

|

13 |

USA 1T/H corn flakes processing machine |

|

14 |

800kh/h industrial corn flakes processing line for sale in Nigeria |

|

Dealed Customer Have Technology Of Corn Flakes Production Process Line At 2021 |

|

|

15 |

Algerian corn flakes 300kg/h production line |

|

16 |

Sudan 200kg/h corn flakes line cereal manufacturing plant |

|

17 |

Moldova small 200kg/h flakes production line |

|

18 |

200kg/h milk breakfast cereal equipment sold in Ukraine |

|

19 |

Nigeria 150KG/H cereal processing technology |

|

20 |

Austria sells industrial processing of breakfast cereals 100kg/h |

|

21 |

Nigeria 150KG/H least processed breakfast cereal machinery |

|

Dealed Customer Have Formula Of corn flakes processing line At 2021 |

|

|

22 |

Breakfast cereal manufacturing process for sale in Pakistan 100kg/h |

|

23 |

Austria sells cereal processing technology 100kg/h |

|

24 |

50KG/H small cereal manufacturing process for sale in Botswana |

|

25 |

Sudan 50kg/h small cereal manufacturing plant |

|

26 |

Algerian kellogg's manufacturing process 300kg/h production line |

|

27 |

300kg/h Technologies and granola manufacturing equipment Involved in Breakfast Cereal Production and Processing sold in Ukraine |

|

28 |

200kg/h Technologies and granola manufacturing equipment in Cereal Processing and Production for sale in Nigeri |

Breakfast Cereal Production and Processing Working Video