This doritos machine is one kinds of extruders design from the doritos tortilla chips extruder manufactour ,which uses corn powder, corn starch, and rice powder as main materials, and then mixing with water, vegetable oil and salt. Although usually made of yellow corn (as pictured), they can also be made of white or red corn or wheat flour. The doritos chips making machine are extruded , compounded into triangle, round, square shapes or others. After fried and flavored, the final snacks will be crispy and tasty like the brand in the market, doritos and tortilla. During compound shaping, some waste edges will be cut down, but it can be reused by grinded into powder and fill in the raw materials in certain proportion. So the doritos chips production Line can maximumly lower the production cost.

Doritos Chips Production Line

How does the snack doritos chips machine work?

|

TWIN SCREW EXTRUDER DORITOS MANUFACTURING PLANT PROCESS |

||

|

NO. |

NAME |

QUANTITY |

|

1 |

MIXER |

1 SET |

|

2 |

SCREW CONVEYOR |

1 SET |

|

4 |

LT 70 L DOUBLE SCREW EXTRUDER WITH COOLING SYSTEM |

1 SET |

|

5 |

ROLLER CUTTING MACHINE |

1 SET |

|

6 |

HOISTER |

1 SET |

|

7 |

SEPARATING AND COOLING ROTARY DRUM |

1 SET |

|

8 |

VIBRATE FEEDER |

1 SET |

|

9 |

CONTINUOUS FRYER |

1 SET |

|

10 |

VIBRATE DE-OILING MACHINE |

1 SET |

|

11 |

LTS-I FLAVORING LINE |

1 SET |

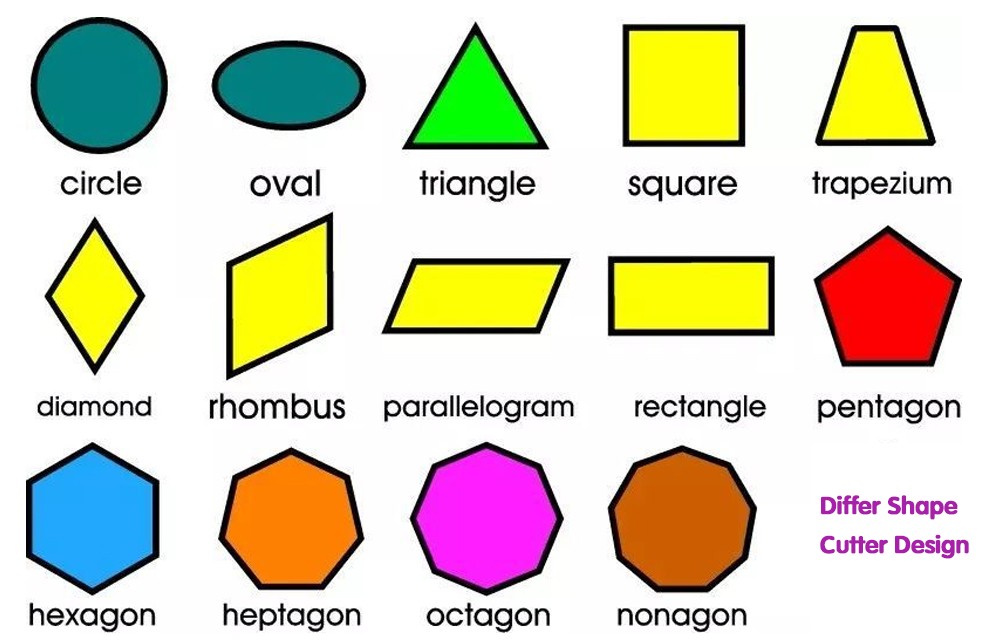

DORITOS EXTRUDER TECHNOLOGY DESIGN

By changing cutting roller on Shaping machine, doritos chips production Line can produce many innovative shapes, like Round, Triangle, Oval, Hexagonal (Sixer) etc. After frying, the chips will be quite crispy; spraying some seasoning powder will make them much savory and delicious.

Doritos Extruder technology Design

HOW TO GET DORITOS SHAPE-CHIPS CUTTING MACHINE

Chips cutting system works together with twin screw extruder.Learn from American technical, makes fabricated tortilla and other chips from a single or doublw screw extruder. When t he extruders had extrusion the daugh sheet, the doritos cutter pulling and press the sheet, have one big roller cutter on this system. the cuter can cutting many diffeent shapes. Our system is much more cost effective than a traditional corn tortilla chip system and allows for complete control of the product texture.

Technical Parameters OF PRODUCTION LINE FOR SALE

|

DIFFERENT MODEL OF DORITOS NACHO CHEESE PROCESSING MACHINE FOR SALE |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

DOM65-1 |

143kw |

100kw |

120--150kg/h |

22000x1200x2200mm |

|

DOM70-1 |

187w |

131kw |

200-250kg/h |

24000x1500x2200mm |

|

DOM85-1 |

232kw |

174kw |

400-500kg/h |

23000*1500*2300mm |

|

DOM75-2 |

240kw |

180kw |

300-500kg/h |

23000*1500*2800mm |

|

DOM95-2 |

368kw |

276kw |

700-1000kg/h |

27000*1500*3000mm |

Doritos Tortilla Chips Extruder

Standard Ingredients FOR RAW MATERIALS RECIPT IN extruder machine

|

Ingredients 1 for doritos chips production Line |

|||

|

Corn Power 75% |

Wheat Flour 25% |

Water 15% |

CaCO3: 0.4% |

|

Ingredients 2 for doritos chips making machine |

|||

|

Corn Powder 100%

|

|

Water 14% |

Salt 1% |

advantages for DORITOS MAKING process lines

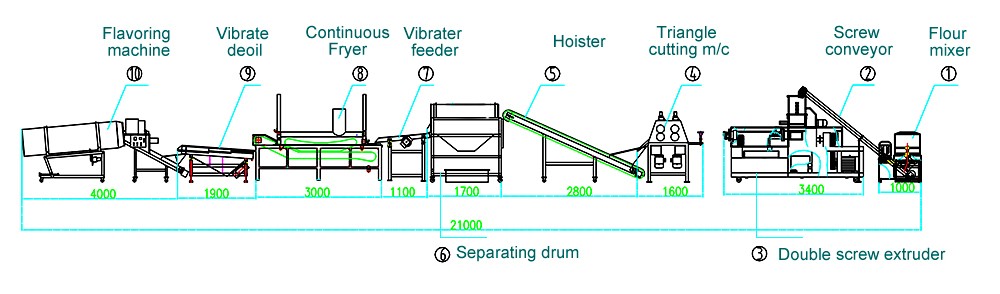

Machine site diagram

|

1 |

this process can make any type raw material |

|

2 |

Control of flow and temperature in the barrel and that make pellet dimensions regularity |

|

3 |

Easy changes in recipes and new product shapes |

|

4 |

Temperature regulation control for every module |

|

5 |

Drastically reduced space requirement |

|

6 |

Capacity ranging from 80 up to1000 kg/h of doritos chips |

Loyal Industial before sales service for doritos chips making machine:

a.) We provide you the suitable solution,which is useful and convenient

b.) We produced the product you need in our factory,you can buy it without any hesitate.

c.) We provide you the factory design and processing line layout and also design for water and electric and gas etc.

d.) With much experienced technical team,we can meet customer personalized requirement,produce the customized machine for you

Loyal Industial after sales service for Doritos Corn Chips Making Machine:

a.) Consultation service before, during, and after sales;

b.) Project planning and corn doritos chips making machine design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.