As Pet Food Extruder Machine manufacturers had designed High Quality Twin Screw pet Extruders used for pet food and fish feed production, developed and tested. The major components of the machine included the feeder hopper, the conditioning chamber (can be choose), the barrel that was a screw member housing and the screw with the die and die holder fitted at the extreme end of the barrel.Twin-screw pet extruder process is mainly composed of a barrel housing and screw, fulfilling extrusion operation together with a die and cutting assembly. The twin- screw pet extruder is characterised by its wide adaptability, sliding conveying in the barrel and self-cleaning function, etc. The twin-screw extruder is usually applied in the production of pet food and fish feed.

Pet Food Extruder Machine

Technical Parameters OF PET food extruder FOR SALE

|

DIFFERENT MODEL OF DOG FOOD EXTRUDER MACHINE FOR SALE |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

PFE-65-1 |

47KW |

30KW |

180kg/h |

3500x950x1850mm |

|

PFE-70-1 |

53KW |

37KW |

200-250kg/h |

3200x760x2000mm |

|

PFE-85-1 |

99KW |

75KW |

500kg/h |

3800*1100*2350mm |

|

PFE-75-2 |

98KW |

75kw |

200-500kg/h |

5200*1100*2800mm |

|

PFE-95-2 |

142kw |

110KW |

600-1200kg/h |

6400*3000*3000mm |

|

PFE-115-3 |

142kw |

110kw |

2T-3Tg/h |

6400*3000*3000mm |

|

PFE-130-3 |

200kw |

170kw |

4T-5Tkg/h |

6400*3000*3000mm |

|

Applied Products:Cat food, Dog food, Bird fodd,fish feed, ,Shrimp feed, Floating fish feed, Tilapia pellet,Sinking feeds,Turtle feed,Crab Feed |

||||

Pet Food Extruder Machine

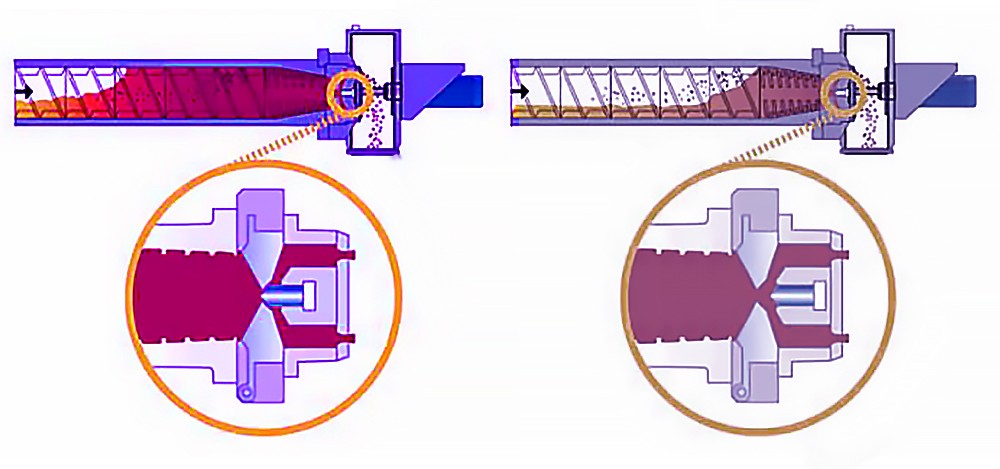

SINGLE SCREW pet EXTRUDER vs. DOUBLE SCREW pet EXTRUDER (Co-Rotation)

Pet Food Extruder Machine

| The parameter of single screw extruder and double screw extruder | ||

|

Item |

SINGLE SCREW EXTRUDER |

DOUBLE SCREW EXTRUDER (Co-Rotation) |

|

Conveying manner |

Feed mash is conveyed forward by friction |

Feed mash is forced to solid forword |

|

Felf cleaning function |

unavailable |

Excellent self-cleaning performance |

|

Running |

Stable and occasional blockage |

Stable and reliable |

|

Heat distribution of feed |

No-uniform |

Uniform |

|

Ingredient adaptability |

Common |

Wider (inel. Ingredient rich of moisture and fat) |

|

Moisture content of ingredient |

10-30% |

5-95% |

|

Product variety |

Limited |

Various |

|

Capacity |

Common |

Relatively High |

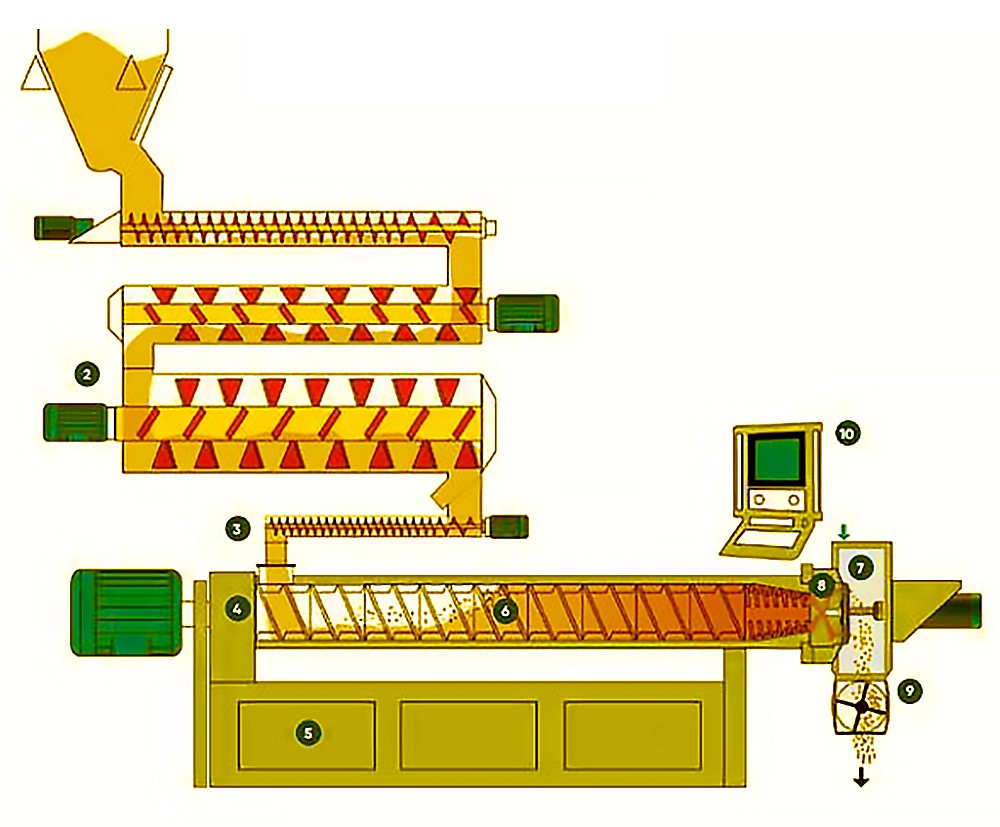

ONE KIND OF BIG CAPACITY TWIN SCREW EXTRUDER FOR PETS FOOD AND FISH FEED

BIG CAPACITY TWIN SCREW EXTRUDER

|

HIGN CAPCITY PET PET EXTRUSION MACHINE STRUCTURE |

|

|

1.Feeder Hopper |

2. PRE-CONDITIONING ---Flexible retention time depending on product requirement --- Constant high mixing efficiency whatever the retention time --Optimal starch cooking through high mixing efficiency |

|

3 FORCED FEEDER --Avoids blockage between conditioner and extruder |

4 Gear Box -- Gear or belt drive ensuring even higher efficiency

|

|

5 EXTRUDER CHASSIS --can choose steam heating and liquid adding system

|

6 SCREW AND BARREL ---screw and barrel configuration, which can be tailor-made for each application

|

|

7 CUTTING SYSTEM ---Standard stanley knife blades |

8 DIE HEAD SYSTEM ---DIfferent Die choose |

|

9 COOLING FAN --control of cooling product not be sticked |

10 PLC CONTROL FOR CHOOSE ---We accept customization control box, custom can ask twin screw extruder adopts more advanced electric controlling system, as PLC extrusion computer or cabinet. All of the main parameters of extruder, like current, voltage, temperature, torque, rotate speed, can be easily found in the extrusion computer or cabinet. |

Sample of pet food

2021 Customer Order Dog Food Manufacturing Process Line Form:

Our dog food making machine is summed up by a number of 25 technical engineers who have more than ten years of experience. Loyal wet pet food extruder production line has a number of pet food project technology patents, which can provide you with the most detailed formula and process documents, which can save dog food production line costs while improving good development in the pet food manufacturing industry.

|

Pet Food Manufacturing Process Line Purchased By Customers Producing Dog Food Products |

|

|

1 |

Chine 300T/Month Industrial Wet Dog Food Production Line |

|

2 |

1T/H Tough Dog Food Production Line For Sale In Puerto Rico |

|

3 |

1T/H Crisp Dog Cat Food Production Line For Sale In Bolivia |

|

4 |

Senegal 1T/H Industrial Dog Food Extrusion Machine |

|

5 |

1T/H Dog Food Machine For Sale In Côte d'Ivoire |

|

6 |

1T/H Industrial Dog Food Equipments Sold In Russia |

|

Old Customers Repurchase Dog Food Manufacturing Process Line In 2021 |

|

|

7 |

1T/H Industrial Dog Food Production Line For Sale In Uzbekistan |

|

8 |

1000kg/h Industrial Automatic Dog Food Machine For Sale In Senegal |

|

9 |

Mozambique 1T/H Industrial Dog Food Manufacturing Line |

|

10 |

Bangladesh 2T/h Industrial Dog Pet Food Making Machine |

|

11 |

1T/H Thai Dog Food Production Line |

|

12 |

Uzbekistan 1T/H Dog Food Production Line |

|

Customers Who Buy Dog Food Production Line Through An Agents |

|

|

13 |

USA 1T/H Pet Food Production Line |

|

14 |

800kh/h Industrial Wet Dog Food Production Line For Sale In Nigeria |

|

15 |

Algerian Dog And Cat Food 300kg/h Production Line |

|

16 |

Sudan 200kg/h Wet Dog Food Making Machine |

|

17 |

Moldova Small 200kg/h Wet Dog Food Production Line |

|

18 |

200kg/h Milk Dog Food Machine Sold In Ukraine |

|

Customers Who Are Building Factories Buy Dog Food Extrusion Machine: |

|

|

19 |

Nigeria 150Kg/H Industrial Wet Dog Bone Food Making Machine |

|

20 |

Austria Sells Industrial Dog Food Machine 100kg/h |

|

21 |

Nigeria 150Kg/H Dog Food Making Machinery |

|

22 |

Vegetable Dog Food Making Machine For Sale In Pakistan 100kg/h |

|

23 |

Austria Sells Industrial Dog Food Machine 100kg/h |

|

24 |

50Kg/H Small Dog Food Extrusion Machine For Sale In Botswana |

|

25 |

Sudan 50kg/h Small Dog Food Production Line |

|

26 |

Algerian Dog Food 300kg/h Production Line |