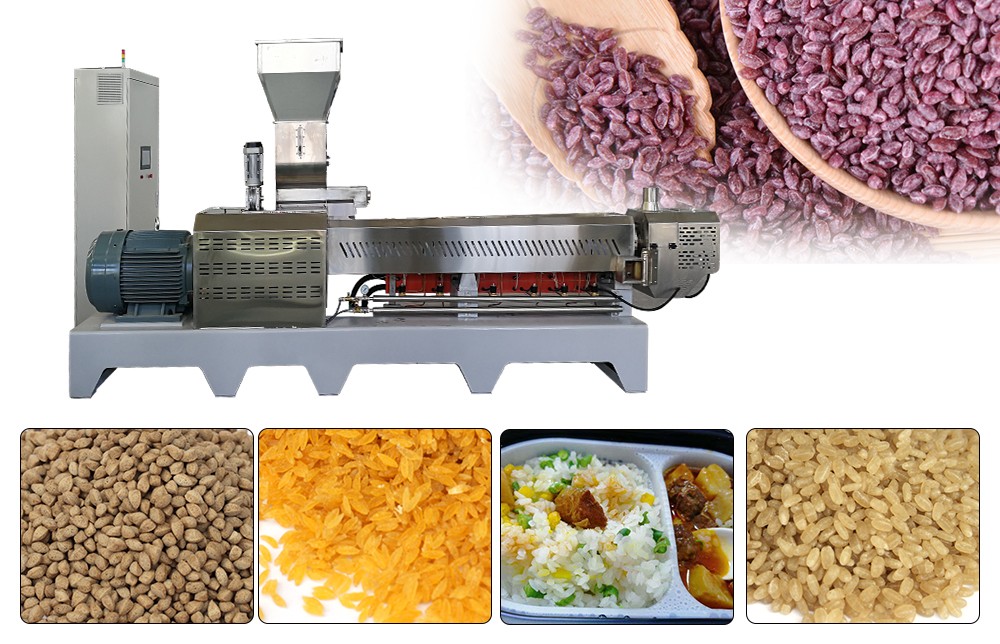

Large Capacity 500kg/h Fortified Rice Kernels (Frk) Extruder Machine

Artificial nutrition fortified rice kernel processing making machine is developed to meet the demands of food nutrition. Large capacity fortified rice kernels (FRK) production line is improved to avoid the loss of nutritional elements in the rice which is made by the traditional rice processing. Fortified rice production line has characters of high automatic, easy operation, energy saving and environmental protection. The raw materials for artificial rice processing can be rice, black rice, buckwheat and other grains (broken rice and rice bran can be reused). Artificial rice extruder machine can also add additional nutrient components, such as vitamins, minerals etc. After extruding, forming and drying, it can get the nutritional artificial rice, which is eaten same as natural rice.

1. Loyal offer Indian engineers--Provide fortified rice machine local installation

2. Loyal with Indian agent.-- Provide fortified rice formula support, fortified rice machine technical training, market information

3.Loyal have 150 successful cases at india-- Fortified rice extruder

4.Loyal process fantastic rice extruder which L D ratio 28:1

Fortified Rice Kernels (Frk) Extruder Machine

WHAT ARE THE DIFFERENCES BETWEEN TRADITIONAL RICE PROCESSING AND ARTIFICIAL RICE PRODUCTION LINES?

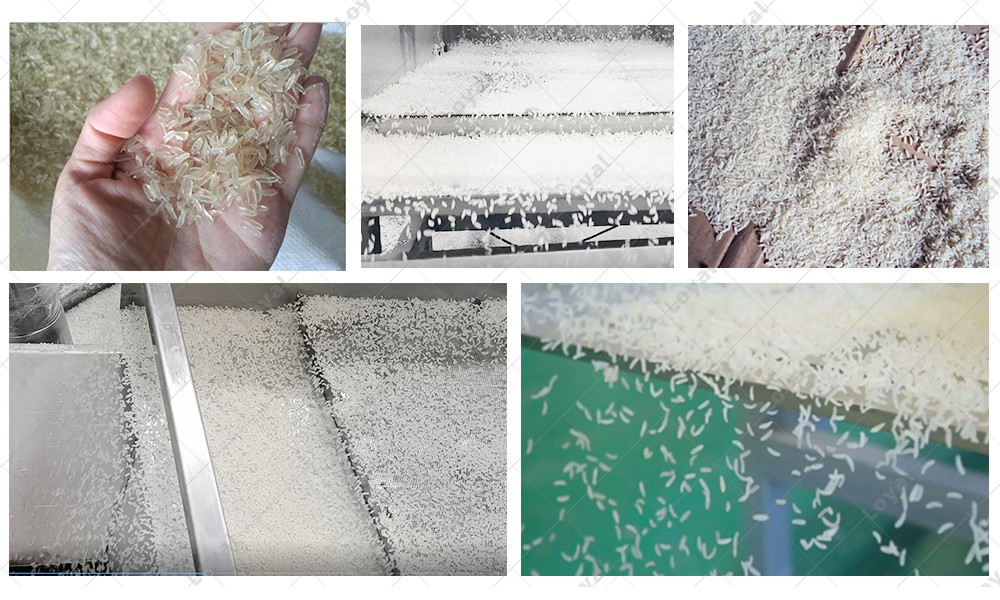

Fortified Rice Kernels (Frk) Extruder Machine Artificial Rice sample

|

Differences Between Traditional Rice Processing And Artificial Rice Production Lines |

||

|

NO. |

Traditional rice processing |

Fortified rice kernels (FRK) processing line |

|

Raw materials |

rice |

Adopts broken rice rice, corn, millet, wheat, oats,buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient. |

|

Progress |

Traditional rice processing is to complete the one-time simple cleaning, shelling, polishing, dust removal and other functions of the rice. |

FRK fortified rice kernel production line takes rice powder as main ingredient, and some other vitamin and mineral as part of ingredient is available. The material is extruded into rice shape by the twin-screw extruder, and dried in a dryer to needed moisture content. |

|

Nutrition |

Rice processing leads to loss of nutritional elements like vitamins and trace elements. During rice processing, more than 20 % of the biomass is lost for human consumption. The traditional rice processing leads to loss of nutrition elements in the rice. |

The extruding technique makes it possible to strengthen and solidify the micro-nutrient in the rice. The loss of vitamins in the process of nutritional rice extrusion is smaller. Low temperature is required in the process of nutrient rice extrusion, the material stays in the sleeve for a short time, the material has less contact with air in the cavity, and some are prone to oxidation Vitamins such as vitamin A and vitamin C will not be lost due to oxidation. Under general extrusion conditions (referring to low temperature, high water content, low screw speed), the nutritional value of vegetable protein usually increases |

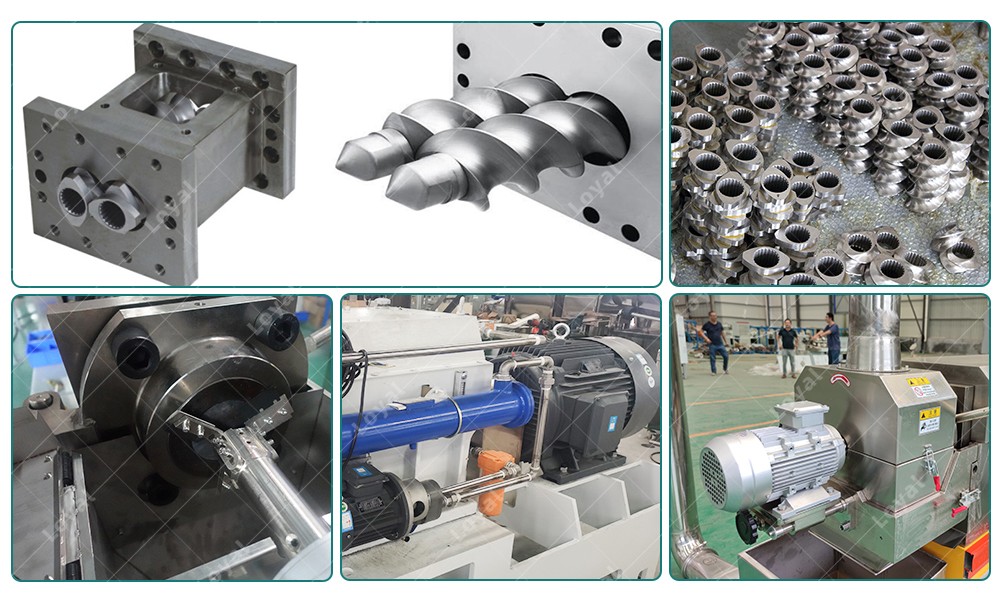

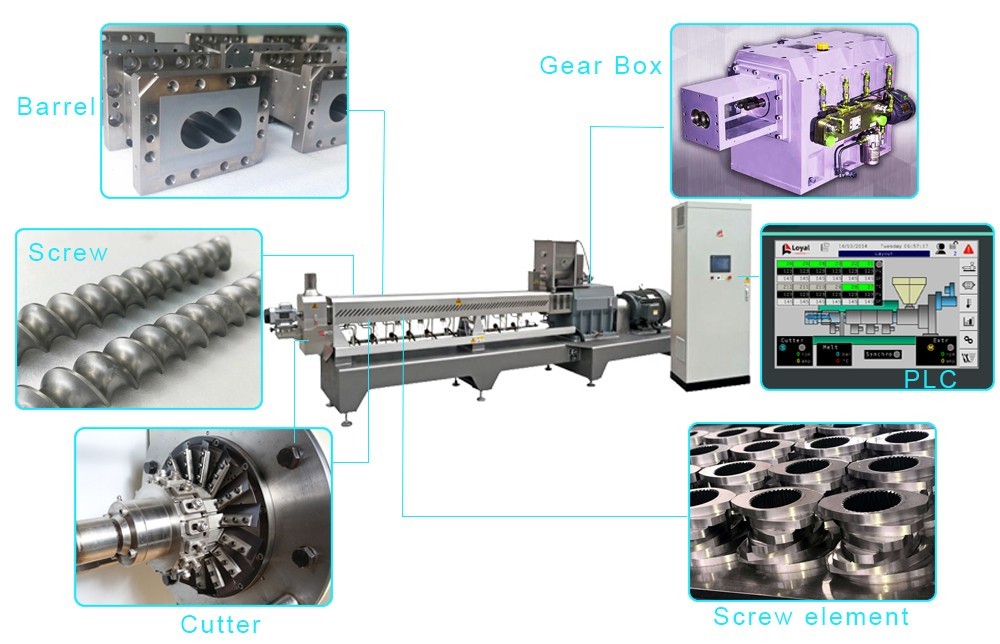

THE MAIN DETAIL DESCRIPTION OF THE FOR FORTIFIED RICE KERNELS (FRK) EXTRUDER MACHINE

Main Detail Of The For Fortified Rice Kernels (frk) Extruder Machine

THE TECHNICAL PARAMETER OF FULL AUTOMATIC FORTIFIED RICE PRODUCTION LINE

|

Main Detail Description Of The For Fortified Rice Kernels (frk) Extruder Machine |

||

|

NO. |

Name |

Brief introduction |

|

1 |

Raw material |

Broken rice, rice flour, other grain flour, vitamin premix, nutrition powder, etc. |

|

2 |

Capacity |

300-500kg/h, 500kg/h-800kg/h, etc. |

|

3 |

Final products |

Artifice rice, fortified rice, nutrition rice, instant rice and so on. |

|

4 |

Machine material |

Stainless steel 304 or as customer’s request |

|

5 |

Shapes |

By changing the dies, same machine can produce various shapes rice, long rice, short rice, thin rice, etc. |

|

5 |

Certificate |

CE,GOST,TUV,BV |

|

6 |

Voltage |

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries |

|

7 |

Heating type |

Gas, Electric, or Steam. |

LY 75 Fortified Rice Kernel Extruder Machine Detail Show

|

Technical Parameter Of Full Automatic Fortified Rice Production Line |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

LY65 |

84kw |

59kw |

100-150g/h |

14000x1200x2200mm |

|

LY70 |

120kw |

84kw |

200-260kg/h |

16000x1500x2200mm |

|

LY75 |

180kw |

135kw |

300-500kg/h |

18000*3500*4300mm |

|

LY85 |

225kw |

158kw |

800-1200kg/h |

20000x3500x4300mm |

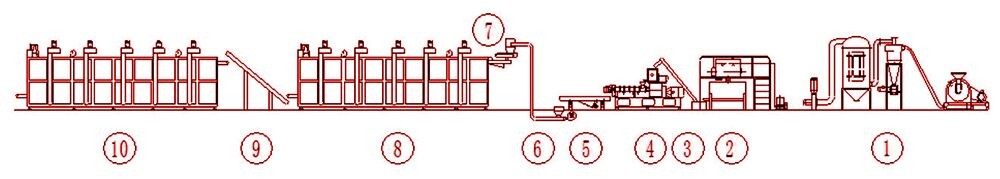

FLOW CHART OF THE COMMERCIAL NUTRITION RICE MAKING MACHINE PROCESSING

Powder mixer→ Screw conveyor→Double screw extruder→Vibrate feeder→Air conveyor→Dryer(→cooling→packaging)

Flow Chart Of Commercial Nutrition Rice Making Machine Processing

WHAT IS THE MAIN FEATURES OF THE DOUBLE SCREW EXTUDER IN THE ARTIFICIAL RICE MAKING PROCESSING LINE?

Artificial Rice Making manufacturing equipment

|

Main Features Of The Double Screw Extuder In The Artificial Rice Making Processing Line |

|

|

1 |

Series of double-screw extruder mainly consist of feeding system, extruding system, cutting system, heating system, lubricating system and controlling system. |

|

2 |

Transfer mixed raw materials from Mixer to co rotating twin screw extrusion |

|

3 |

Automatic lubricating and forced cooling make sure that twin extruder machine performs safely and extends using life. Feeding system, extruding system and cutting system all adopt frequency conversion timing to gain powerful drive, stable perform, and electricity saving. |

|

4 |

Screw are made of alloy and processed by special technique to possess high intensity, abrasion resistant and longer using life. |

|

5 |

By means of designing different structures and slenderness ratios according to needs of products, screw extruding system can meet different technology demands. |

WHAT IS THE TECHNICAL ADVANTAGES OF THE AUTOMATIC EXTRUDED ARTIFICIAL RICE PRODUCTION LINE?

Fortified Rice Making Machine Detail Picture Show

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

Process for making artificial rice grains, coprises mixing rice flour, water and oil and cooking them in extruder, forming into rice-grain shapes, drying and cooling in low temperature. The technique makes it feasible to avoid the loss of nutrition.

WHAT IS THE APPLICATION OF THE COMMERCIAL FORTIFIED RICE PRODUCTION LINE?

With the broken rice, rice flour, other grain flour, vitamin premix, nutrition powder, etc you can get artificial rice, fortified rice, nutrition rice, instant rice in different size, such as long rice, round rice, short rice, golden rice.

Fortified Rice Production Line Processin sample

Customer Purchase Case Of Fortified Rice Kernels (Frk) Extruder Machine

Fortified Rice Kernels (Frk) Extruder Machine Workshop production line

|

Customer Cases For Industrial Instant Rice Making Machine Fortified Rice Processing Line For Factory In 2021 |

|

|

1 |

200kg/h Cost Of Industrial Instant Rice Making Machine Sold In India |

|

2 |

1t/h Industrial Instant Rice Making Machine For Sale In Puerto Rico Agent |

|

3 |

Large Capacity 500kg/h Industrial Instant Rice Making Machine For Sale In India |

|

4 |

Senegal 1t/h Industrial Instant Rice Making Machine |

|

5 |

1t/h Fortified Rice Processing Line For Sale In Côte d'Ivoire |

|

6 |

China 300t/Year Industrial Instant Rice Making Machine Fortified Rice Processing Line |

|

Customer Case Of Fortified Rice Equipment At 2021 |

|

|

1 |

1t/h Fortified Rice Equipment For Factory In India |

|

2 |

1000kg/h Industrial Instant Rice Making Machine For Sale In India |

|

3 |

Mozambique 1t/h Industrial Instant Rice Making Machine |

|

4 |

1t/h India Full Automatic Instant Rice Processing Line For Factory |

|

5 |

Usa 1t/h Full Automatic Instant Rice Processing Line |

|

6 |

800kg/h Full Automatic Instant Rice Processing Line For Sale In India |