A Comprehensive Analysis of Nutrition Bar Making Machines in 2025

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

With the rapid expansion of the health food market, nutrition bars have become an important choice for consumers' daily energy supplementation and fitness diets, bringing unprecedented development opportunities to the food processing industry. Driven by this trend, enterprises have placed higher demands on production efficiency, product stability, and energy utilization. Traditional semi-automatic processing methods can no longer meet the needs of large-scale, high-consistency production, while automated and energy-saving equipment is gradually becoming the core driving force for industry upgrading. In particular, fully automated nutrition bar equipment capable of continuous, large-scale, and stable production is becoming the preferred solution for modern food factory construction.

Professor Zhao Mouming, Vice Chairman of the Chinese Institute of Food Science and Technology, once pointed out: "The core of the modernization of the food industry lies in the intelligent upgrading of equipment; the level of equipment determines the future competitiveness of enterprises." This view provides clear guidance for the industry's development direction and confirms the strategic value of intelligent equipment in food manufacturing. Against the backdrop of accelerated development driven by both policy and market demand, fully automated nutrition bar production lines equipped with intelligent control systems, energy-saving modules, and process optimization technologies have become the new standard in the industry.

This article will provide a comprehensive analysis of the background, industry trends, and energy-efficient processes of fully automated nutrition bar equipment, offering guidance for companies that are currently developing or upgrading their nutrition bar processing equipment.

Core Components and Performance Highlights of a Fully Automatic Nutrition Bar Maker

Modern food processing companies are increasingly relying on fully automated nutrition bar production systems with high levels of automation and strong structural integration. To meet the demands of large-scale, high-stability, and energy-efficient production, a complete and mature fully automated nutrition bar production line typically consists of six core modules: a sugar boiling tank, a powder mixing machine, an elevator, a cutting and forming machine, a turning machine, and a packaging machine. These modules are interconnected through an intelligent control system to ensure that production efficiency, product consistency, and energy consumption control are at an advanced level in the industry.

|

Automatic mixing module |

Responsible for precisely mixing ingredients such as nuts, oats, protein powder, and syrup according to a pre-set formula to achieve the best shaping state. |

|

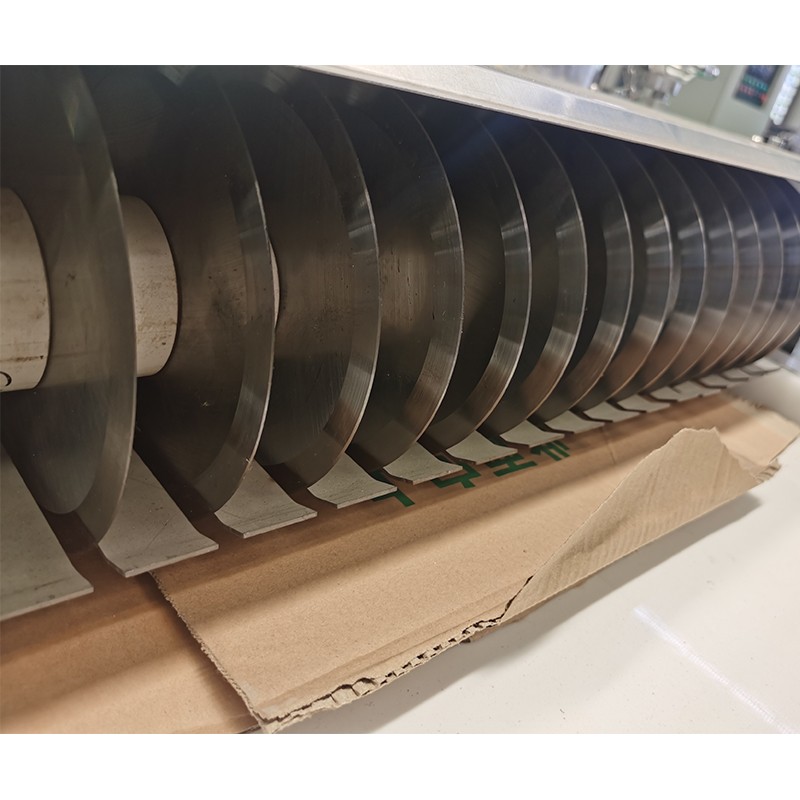

Suppression and spreading system |

The material is formed into uniform thickness sheets by an adjustable pressure roller, providing a stable foundation for subsequent cutting. |

|

Fully automatic block forming machine |

The key to ensuring product specification consistency lies in its high-speed cutter and intelligent positioning system, which can cut pieces with millimeter-level precision. |

Standardized Process Flow of the Nutrition Bar Production Line

A highly automated nutrition bar production line consists of a series of standardized and interconnected processes. Each stage plays a critical role in ensuring product consistency, production efficiency, safety, and energy optimization. Below is a complete overview of the standard process flow used in modern factories:

1 .Raw Material Preparation:This step includes weighing, screening, and pre-treating raw materials such as grains, nuts, protein powders, malt syrup, and dietary fiber powders. Standardized preparation ensures consistent product quality and stable downstream processing.

2. Syrup Cooking:Using an automatic heating system, the syrup cooker precisely controls temperature, concentration, and viscosity. The stable syrup condition is essential for ensuring proper binding and shaping of the bars.

3.Mixing and Blending:The fully automatic mixer blends cooked syrup with dry ingredients. The mixing intensity, duration, and paddle speed are controlled digitally to guarantee uniform distribution and prevent over-mixing.

4 Conveying and Feeding:The elevator and transfer conveyors move the mixed materials to the forming section. The use of food-grade belts and stable conveying speeds helps maintain the integrity and texture of the material.

5 .Cutting and Forming:The cutting and forming machine shapes the mixture into continuous sheets and precisely cuts them into uniform bars. Servo-controlled blades ensure accuracy in size, weight, and appearance.

Cooling Process:The bars pass through a cooling tunnel to stabilize structure and prevent deformation. Controlled airflow and temperature maintain product quality across different batches.

7. Packaging:Finally, the packaging machine completes sealing, date coding, and labeling. Optional integration with metal detectors and weight checkers ensures product safety before entering the market.

Energy-Saving Technological Breakthroughs in Fully Automatic Nutrition Bar Equipment

Amid the food processing industry's shift toward intelligence and green development, fully automatic nutrition bar equipment has achieved remarkable technological advancements in energy conservation and consumption reduction. These breakthroughs not only enhance the operational efficiency of entire nutrition bar production lines but also further lower enterprises' energy expenses, delivering superior return on investment. This chapter will provide a professional analysis focusing on key dimensions including "energy-saving structural optimization, intelligent control management, improved material utilization, and equipment operational stability."

1 .Structural Energy-Saving Design: The First Step to Reducing Energy Consumption

Modern fully automatic nutrition bar equipment minimizes energy loss at the source through optimized mechanical structures, including:Low-Power High-Efficiency Drive Systems、 Double-Layer Insulated Syrup Cooking Systems、Friction Optimization of Conveyor Structures

2 .Intelligent Control Systems: The Core Driver of Energy Conservation

Fully automatic nutrition bar equipment generally adopts an intelligent control mode combining PLC and touch screens, which not only improves production automation but also enables precise and controllable energy-saving management.

3 .Energy Reuse Technology: Further Enhancing Energy-Saving Performance

Some new nutrition bar production lines have begun to integrate cyclic energy systems, including:

(1) Waste Heat Recovery Structure

Waste heat released by the syrup cooking pot is recycled to preheat raw materials;

Improves overall thermal energy utilization rate by 18%–22%.

(2) Local Air Cooling Instead of Water Cooling

Energy-saving air cooling systems can be used in cutting and cooling conveyor processes;

Reduces water consumption and cooling energy consumption.

4. Improved Material Utilization: Reducing Waste Equals Energy Conservation

Lowering raw material waste is also a crucial component of energy conservation:Precise Control of Cutting Weight and Dimensions、Uniform Mixing to Minimize Material Waste。

5.Enhanced Equipment Stability: Avoiding Extra Energy Consumption from Unplanned Shutdowns

Stable operation means the equipment does not require repeated startup and heating, thereby reducing energy consumption. Durable Whole Machine with Lower Failure Rate、Online Monitoring to Reduce Shutdowns.

Quality control and safety standards for high-efficiency nutrition bar production lines

As the food processing industry moves towards intelligent, standardized, and high-quality production, the quality management system and food safety control level of nutrition bar production lines have become core indicators of enterprise competitiveness. Highly efficient and stable fully automated nutrition bar equipment not only requires high production capacity but also ensures that every nutrition bar meets food safety regulations, product consistency standards, and consumers' expectations for nutrition and health. 1. Raw material quality control: Ensuring product safety and stability from the source. 2. Production process control: Ensuring the consistency and stability of nutrition bars. 3. Finished product inspection system: Ensuring that every nutrition bar meets market requirements. 4. Equipment hygiene design: Meeting food processing safety requirements. 5. Traceability system construction: Giving each nutrition bar an "ID card" and automatically recording production data. High quality and high safety standards are the lifeline of nutrition bar production lines.

Enterprise value and return on investment brought by fully automated nutrition bar equipment

High-efficiency fully automatic nutrition bar equipment not only requires fast production speed and large capacity but also needs to establish a rigorous quality control system covering four aspects: "raw materials—process—equipment—finished products." The combination of advanced automation technology and food safety standards has elevated modern nutrition bar production lines to new heights in efficiency, quality, and safety, helping enterprises maintain a leading position in the highly competitive market.

Enterprise Value and Return on Investment (ROI) Brought by Fully Automatic Nutrition Bar Equipment

Reduced Production Costs: Automated Equipment Doubles Production Capacity. For nutrition bar manufacturers, the primary value of introducing fully automated nutrition bar production lines lies in "efficiency improvement" and "cost reduction." As Liu Zhaofeng, a researcher and expert in food equipment in China, stated:

"Automation in food processing is not only a tool for increasing production capacity, but also a core means of reducing overall costs and minimizing human uncertainty." Improved Product Consistency: Helping Companies Stand Out in Competition. The more intense the market competition, the more crucial product quality becomes in determining success or failure. Energy Saving and Consumption Reduction: Lowering Long-Term Operating Costs and Enhancing Brand Competitiveness and Market Expansion Capabilities. Owning an advanced nutrition bar production line is not just a production tool, but also a "symbol of strength." Return on Investment (ROI) Forecast Example: Companies are generally concerned about the payback period of automated production lines. Sustainable Strategic Value Brought by the Equipment. In addition to short-term returns, fully automated nutrition bar equipment also has long-term strategic advantages: enabling companies to develop new products (high-protein bars, low-sugar bars, meal replacement bars, etc.); facilitating digital factory upgrades; supporting future integration with MES and ERP systems; and laying the foundation for companies to transform into smart factories.

Fully Automatic Nutrition Bar Equipment Will Lead the Intelligent Future of Nutrition Bar Production Lines

As demand for healthy food continues to grow, the nutrition bar industry is entering a new phase of higher standards, greater efficiency, and enhanced competitiveness. In this market environment, fully automatic nutrition bar equipment is no longer merely a tool to boost production capacity, but a key driver for the upgrading of the food manufacturing industry. Through comprehensive breakthroughs in automation, energy conservation, intelligence, and standardization, it has elevated modern nutrition bar production lines to new heights in efficiency, quality, safety, and sustainability.

The fully automated processing flow frees enterprises from the limitations of traditional production, enabling high-speed, continuous, and stable output; multi-dimensional energy-saving technologies drive sustained reductions in production costs; and multi-layered quality and safety systems effectively ensure the consistency and reliability of food quality. For enterprises, this not only means improved production capacity but also comprehensive enhancements in brand competitiveness, supply chain efficiency, and market expansion capabilities.

Fully automatic nutrition bar equipment is precisely one of the practical manifestations of this future.

It is foreseeable that within the next three to five years, intelligent and automated nutrition bar equipment will become the industry standard. Enterprises that take the lead in completing equipment upgrades will gain a competitive edge in the industry. Nutrition bar production lines with full-process intelligent collaboration—from syrup cooking, mixing, cutting, and conveying to packaging—will accelerate the transformation of nutritious food manufacturing toward high-endization, refinement, and intelligence.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com