The Ultimate Guide To Corn Flakes Production Machinery Updated 2025

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

Introduction

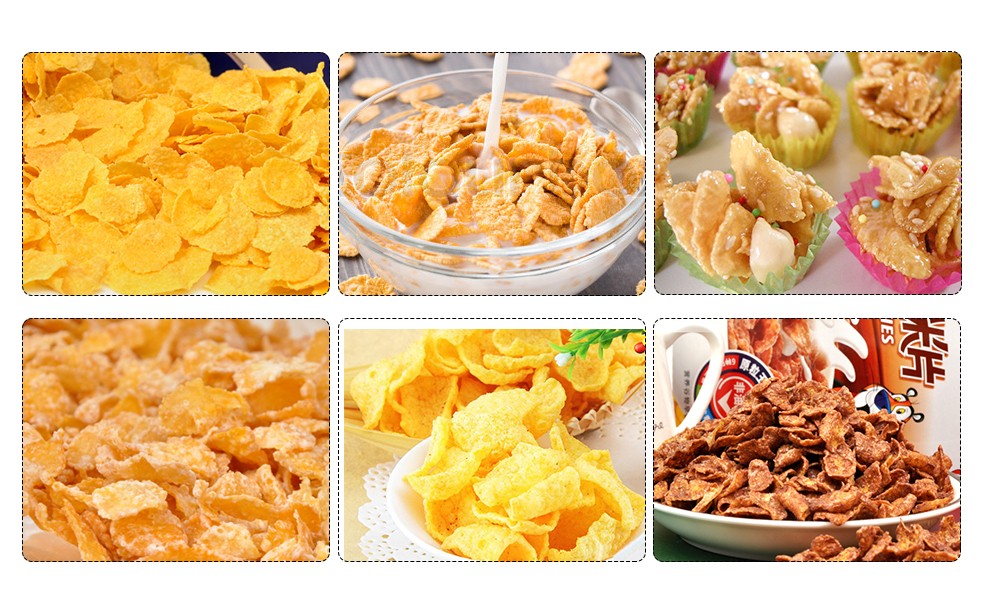

Corn flakes have become a staple in breakfast tables across the globe, loved for their crispy texture and versatile flavor profiles. The journey from raw corn to the perfectly flaked cereal involves a series of sophisticated machinery and processes that have evolved significantly over the years. This article delves into the intricacies of corn flakes production machinery, highlighting advancements, challenges, and future prospects in this dynamic industry. As Dr. Emily Carter, a renowned food scientist, aptly puts it, “The art of transforming corn into flakes is a testament to human ingenuity and the relentless pursuit of perfecting food processing techniques.”

The Core Machinery in Corn Flakes Production

The heart of corn flakes production lies in the extrusion and flaking processes, which are meticulously executed by specialized machinery. The first step involves the use of a twin-screw extruder, a versatile piece of equipment that handles the initial mixing and cooking of cornmeal with water and other additives. This machine, available in various sizes (commonly 65, 70, 75, 80, and 95 mm screw diameters), is designed to handle different production capacities. As Dr. Carter explains, “The twin-screw extruder is crucial because it allows for precise control over the cooking process, ensuring uniform texture and nutritional content in the final product.”

Detailed Breakdown of the Twin-Screw Extruder

The twin-screw extruder is a complex machine with multiple components, each serving a specific function. The feeding system ensures a consistent supply of raw materials into the extruder. The screw system is responsible for mixing and conveying the material through the barrel. The heating and cooling systems maintain optimal temperatures for cooking and cooling the material. The cutting system shapes the extruded material into small pellets. Dr. Carter highlights the importance of each component: “Each part of the extruder plays a vital role in ensuring the consistency and quality of the corn flakes.”

The Flaking Mill: From Pellets to Flakes

Following extrusion, the cornmeal is transformed into small pellets, which are then fed into a flaking mill. This mill applies pressure to flatten the pellets into the familiar flake shape. The flaking mill’s design ensures that the flakes maintain their integrity and crispiness, a critical factor in the final product’s appeal. According to industry expert Mr. John Harris, “The flaking mill is where the magic happens. It’s all about getting the right pressure and temperature to achieve that perfect flake.”

Innovations in Flaking Technology

Recent advancements in flaking technology have focused on improving efficiency and reducing energy consumption. Modern flaking mills are equipped with advanced sensors and control systems that monitor and adjust pressure and temperature in real-time. This ensures consistent flake quality and reduces the risk of defects. Dr. Carter notes, “Innovations in flaking technology have significantly improved the efficiency and consistency of corn flakes production.”

The Role of Drying and Baking Systems

Once the corn flakes are formed, they undergo a series of drying and baking processes to remove excess moisture and enhance flavor. Drying machines come in various configurations, including single, triple, and quintuple layers, depending on the production scale. These machines use different heating methods such as electric, gas, or steam, each with its own advantages. Electric drying is cost-effective and easy to install, while steam drying offers high efficiency albeit at a higher initial cost. As Mr. Harris notes, “Choosing the right drying method depends on local energy costs and availability. It’s a balance between efficiency and economy.”

Advanced Drying Techniques

Modern drying machines are equipped with advanced techniques such as infrared drying and microwave drying. Infrared drying uses radiant heat to quickly remove moisture from the flakes, while microwave drying penetrates deeper into the material, ensuring uniform drying. Dr. Carter explains, “Advanced drying techniques like infrared and microwave drying have revolutionized the industry by improving drying efficiency and reducing energy consumption.”

The High-Temperature Oven: Final Baking

After drying, the corn flakes enter a high-temperature oven for final baking. This step is crucial for achieving the desired crispiness and flavor. Modern ovens are equipped with advanced temperature control systems that ensure uniform baking. Dr. Carter highlights the importance of this step: “The baking process not only removes moisture but also caramelizes sugars, giving corn flakes their characteristic golden color and sweet taste.”

Innovations in Baking Technology

Innovations in baking technology have focused on improving energy efficiency and reducing baking times. Modern ovens are equipped with rapid heat transfer systems that quickly and evenly distribute heat throughout the oven. This ensures consistent baking and reduces energy consumption. Mr. Harris notes, “Innovations in baking technology have significantly improved the efficiency and consistency of the baking process.”

The Integration of Flavoring and Coating Systems

One of the most exciting advancements in corn flakes production is the integration of flavoring and coating systems. These systems allow manufacturers to add a wide range of flavors and nutritional enhancements to their products. A sugar-coating system, for instance, involves spraying a sugar solution onto the flakes and then drying them in a specialized oven. This process adds sweetness and improves shelf life. As Dr. Carter explains, “Flavoring and coating systems have revolutionized the corn flakes industry, allowing for endless possibilities in product innovation.”

Advanced Flavoring Techniques

Modern flavoring systems are equipped with advanced techniques such as ultrasonic spraying and electrostatic coating. Ultrasonic spraying uses high-frequency sound waves to create a fine mist of flavoring agents, ensuring even distribution. Electrostatic coating uses an electric charge to attract flavoring agents to the flakes, improving adhesion and reducing waste. Dr. Carter notes, “Advanced flavoring techniques like ultrasonic spraying and electrostatic coating have significantly improved the efficiency and consistency of flavoring.”

The Future of Flavoring and Coating

Looking ahead, the future of flavoring and coating systems is promising. Innovations in nanotechnology and biotechnology are expected to bring new opportunities for creating unique and nutritious flavors. Dr. Carter predicts, “The future of flavoring and coating systems will be driven by advancements in nanotechnology and biotechnology, allowing for the creation of innovative and nutritious flavors.”

Automation and Quality Control in Modern Production Lines

The modern corn flakes production line is a marvel of automation and precision. Advanced control systems, often equipped with PLCs (Programmable Logic Controllers) and HMI (Human-Machine Interface) panels, allow operators to monitor and adjust the production process in real-time. These systems ensure consistent product quality and reduce the risk of human error. As Dr. Carter emphasizes, “Automation is key to maintaining high standards of quality and efficiency in corn flakes production.”

Advanced Quality Control Systems

Modern production lines are equipped with advanced quality control systems that use sophisticated sensors and cameras to inspect the flakes for defects. These systems can detect and remove defective flakes in real-time, ensuring that only the highest quality products reach consumers. Mr. Harris adds, “Our investment in quality control technology has significantly improved our product consistency and customer satisfaction.”

The Role of Big Data and Analytics

Big data and analytics are playing an increasingly important role in modern production lines. By analyzing data from various sensors and systems, manufacturers can optimize production processes, reduce waste, and improve efficiency. Dr. Carter notes, “Big data and analytics are transforming the industry by providing valuable insights into production processes and helping manufacturers make data-driven decisions.”

Future Trends and Innovations

Looking ahead, the corn flakes industry is poised for further innovation and growth. One emerging trend is the focus on sustainability. Manufacturers are increasingly looking for ways to reduce their environmental footprint, from using energy-efficient machinery to sourcing sustainable raw materials. Dr. Carter predicts, “Sustainability will be a driving force in the future of corn flakes production. We will see more eco-friendly practices and technologies being adopted.”

The Rise of Personalization

Another area of innovation is personalization. With the rise of health-conscious consumers, there is a growing demand for customized corn flakes products. Manufacturers are exploring ways to tailor their products to meet specific dietary needs, such as gluten-free or low-sugar options. Mr. Harris notes, “Personalization is the future. We are seeing a shift towards more customized products that cater to individual health and taste preferences.”

The Impact of Technology

Advancements in technology, such as artificial intelligence and machine learning, are expected to bring significant changes to the industry. These technologies can be used to optimize production processes, improve quality control, and enhance product innovation. Dr. Carter predicts, “The future of corn flakes production will be heavily influenced by advancements in artificial intelligence and machine learning, bringing new opportunities for optimization and innovation.”

The parameter of the corn flakes

|

|

LY65 |

LY70 |

LY75 |

|

Installed power |

130kw |

150kw |

180kw |

|

Real power |

80kw |

110kw |

140kw |

|

Capacity |

100-120kg/h |

200-240kg/h |

300-500kg/h |

|

Dimension |

38000*1200*2200mm |

41000*1500*2200mm |

43000*3500*4300mm |

Conclusion

The production of corn flakes is a complex and fascinating process that involves a combination of traditional techniques and modern technology. From the initial extrusion to the final packaging, each step is meticulously designed to ensure the highest quality product. As the industry continues to evolve, we can expect to see further innovations that enhance both the nutritional value and the sensory appeal of corn flakes. As Dr. Emily Carter concludes, “The journey of corn flakes production is a continuous one, driven by the need to innovate and improve. The future looks bright for this beloved breakfast staple.”

This article provides a comprehensive overview of the machinery and processes involved in corn flakes production, highlighting the importance of innovation and quality control. By understanding these elements, we gain a deeper appreciation for the effort and expertise that goes into creating this popular breakfast food.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/