Unlock The Secret To Perfect Breakfast Cereal Making Machine:A Breakfast Cereal Making Machine Recipe Guide

Breakfast Cereal Making Machine Description

Cereal breakfast foods mainly refer to corn cereals manufacturing processed with modern technology using cereals (corn, rice, wheat, oats, etc.) as the main raw materials.Breakfast corn cereal is a kind of crispy food, with the characteristics of hard to be steeped broken and strong grain taste.

Breakfast Cereal Making Machine includes mixing, extruding ,drying,sugar coating and drying.breakfast cereal production line can be used as a snack or served with milk and coffee.Change molds and choose the right process to produce circles, balls, sheets, stars, letters and other products,and produce core filling snack food, filling biscuit ,nutrition breakfast, corn flakes and other puffed foods.

Breakfast cereals, as a common food in people's daily lives, are very popular, rich in nutrients, and delicious. Consumers also use them as part of their regular diet. Their prospects for development are very broad. Therefore, a cornflake production line is an excellent investment choice.

Breakfast cereal machines feature good quality, high efficiency, cost savings, and high economic benefits, overcoming the drawbacks of previous equipment and offering many new superior performance advantages.

Introduction to Breakfast Cereal Production Technology

The Breakfast Cereal process line stands as the backbone of today’s fast-paced, health-conscious food industry, transforming raw grains into nutrient-rich, ready-to-eat cereals. Modern Breakfast Cereal production lines integrate advanced automation and precision engineering to meet the surging global demand for convenient, wholesome breakfast options. These systems ensure consistent quality across billions of servings annually.

Automation plays a pivotal role in scaling production while maintaining nutritional integrity. Breakfast Cereal Making Machines employ programmable logic controllers (PLCs) to automate tasks like ingredient dosing, mixing ratios, and cooking parameters. This minimizes human error and ensures uniform texture and flavor—critical for brand loyalty in competitive markets. For instance, automated extrusion systems adjust pressure and temperature in real time to preserve heat-sensitive vitamins like B12 and iron, addressing consumer demand for fortified cereals.

As sustainability becomes a non-negotiable priority, next-gen Breakfast Cereal process lines are designed to reduce waste and energy use.

Product Description Of Breakfast Cereal Production Line

Corn flakes/Breakfast cereal is a kind of crispy food, with the characteristics of hard to be steeped broken and strong grain taste. Cereal manufacturing plant is mainly made from corn flour and other grains powder. Granola manufacturing equipment can be used as a snack or served with milk and coffee.Change molds and choose the right process to produce circles, balls, sheets, stars, letters and other products,and produce core filling snack food, filling biscuit ,nutrition breakfast, corn flakes and other puffed foods.

Key Components of a Breakfast Cereal Production Line

A modern Breakfast Cereal production line combines precision engineering and food science to transform raw grains into nutritious, ready-to-eat cereals.

Here’s a breakdown of its essential components:

1. Raw Material Handling: Cleaning, Mixing, and Preconditioning

The process begins with grains like oats, corn, or wheat being cleaned to remove impurities. Advanced Breakfast Cereal Making Machines use optical sorters and air classifiers to ensure only high-quality grains proceed. Next, ingredients are mixed and preconditioned with water or steam to soften the grains, preparing them for extrusion.

2. Extrusion & Shaping: Crafting Textures

Extrusion is where the magic happens. The Breakfast Cereal process line employs twin-screw extruders that apply heat and pressure to cook the dough. By adjusting die shapes and cutting mechanisms, these machines create diverse textures—flakes, puffs, or clusters.

3. Drying & Seasoning Systems

Post-extrusion, cereals move through multi-zone dryers to achieve the ideal moisture content (typically 3-5%). Pre-dryer preserves crispness without compromising nutrients. Flavor system—like honey or chocolate—are applied via precision spray systems, ensuring even distribution for consistent taste.

Breakfast Cereal Extruder

breakfast cereal making machine manufacturing process

|

Function Of Each Breakfast Cereal Machine |

||

|

1 |

Flour Mixer |

Mixing materials |

|

2 |

Screw Conveyor |

Transfer cereals snacks raw materials from Mixer to Twin screw Extruder |

|

3 |

Twin screw extruder |

Extruding corn cereals |

|

4 |

Air Conveyor |

Transfer cereals snacks to dryer |

|

5 |

Commercial food dryer |

Drying process in food industry to remove moisture |

|

6 |

Air Conveyor |

Transfer cereals snacks to Sugar Sprayer |

|

7 |

Sugar Sprayer |

Spraying sugar on cereals snacks surface |

|

8 |

Commercial food dryer |

Drying again to remove sugar moisture |

|

9 |

Cooling machine |

Cooling cereals snacks with cooling fan |

|

10 |

cereals snacks packaging |

Packing cereales corn flakes in bags |

Parts of breakfast cereal Production Line

(1) Mixer. Mix corn meal or corn grits with nutritional additives and a proportion of water. This is the first step in the work of the corn flakes processing line.

(2) Feeder. Feed the mixed material into the hopper of the extruder. This is the second step in the work of the corn flakes processing line.

(3) Extruder. The raw material enters the hopper. In a pressurized system, small spherical particles are produced. This is the third step in the work of the corn flakes processing line.

(4) Vibrating cooler. The granules are dispersed after entering the tablet machine, avoiding overlapping and pressing together. This is the fourth step in the work of the corn flakes processing line.

(5) Air conveyor. The granules are transported to the tablet press. This is the fifth step in the work of the corn flakes processing line.

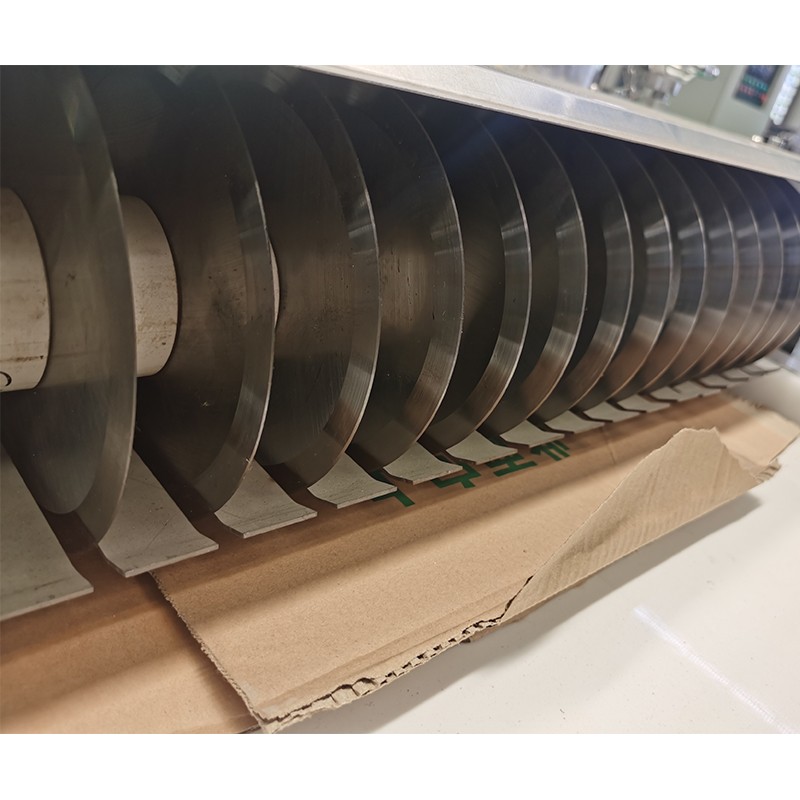

(6) Flaking machine. The pellets are pressed into flakes, known as corn flakes. This is the sixth step in the work of the corn flakes processing line.

(7) Air conveyor. Send the cornflakes to the oven. This is the seventh step in the work of the corn flakes processing line.

(8) Multi-layer oven. Ovens are mostly electric ovens. The temperature is adjusted by the control cabinet between 0-200 degrees. The inner pocket is made of stainless steel double mesh. Baking time can be adjusted based on speed to remove moisture. This is the eighth step in the work of the corn flakes processing line.

(9) Seasoning system. The seasoning line has octagonal cylinder, lifting cylinder, single cylinder and double cylinder. According to the output and product properties, there are oil spraying, sugar spraying and coating equipment. This is the ninth step in the work of the corn flakes processing line .

(10) Packaging machine. The finished pellets are conveyed to the crushing unit. This is the last step in the work of the corn flakes processing line .

Breakfast Cereal Production Line Flow Chart Design

Raw material formulating--Mixer-double screw extruder--air conveyor--pre-dryer--hoist--high temperature baking machine---air conveyor--sugar sprayer--- multi-layer oven---cooling conveyor--Packing

|

Corn Flakes Production Line Corn Flakes Making Machine |

|

|

NO. |

Equipment Of Corn Flakes Production Line |

|

1 |

Flour Mixer |

|

2 |

Screw Conveyor |

|

3 |

Double Screw Extruder |

|

4 |

Vibrate Cooler |

|

5 |

Air Conveyor |

|

6 |

Pre-Dryer |

|

7 |

Hoister |

|

8 |

Vibrate Feeder |

|

9 |

High Temperature Baking Machine |

|

10 |

Sugar Sprayer |

|

11 |

Sugar Coating System |

|

12 |

Multi- Layer Oven |

|

13 |

Cooling Conveyor |

|

14 |

Packaging Machine |

Breakfast Cereal Processing Line

Technical Parameters For breakfast cereal production line

|

Different model for sale of cereal making machine |

|||

|

Model |

Installed Power |

Power Consumption |

Output |

|

LY65 |

140kw |

90kw |

100-150g/h |

|

LY70 |

160kw |

120kw |

180-250kg/h |

|

KING75 |

190kw |

140kw |

300-500kg/h |

|

KING95 |

240kw |

190kw |

800-1000kg/h |

Innovations Driving Sustainable Production

The Breakfast Cereal production line is undergoing a sustainability revolution, driven by cutting-edge technologies that minimize environmental impact without compromising efficiency. Here are the breakthroughs reshaping the industry:

1. Smart Sensors for Real-Time Quality Control

Advanced Breakfast Cereal Making Machines now incorporate IoT-enabled sensors to monitor variables like moisture, temperature, and texture during extrusion and drying. These systems instantly detect deviations, reducing waste by up to 20% and ensuring consistent product quality. For example, humidity sensors adjust drying times dynamically, preventing overcrisp or soggy batches.

2. Plant-Based Packaging Integration

Sustainable packaging is no longer an afterthought. Some Breakfast Cereal process lines now feature in-line systems that form bags or boxes from compostable materials like cornstarch or seaweed. These machines mold, fill, and seal packaging in sync with production speeds, eliminating plastic use while maintaining freshness.

3. AI-Driven Process Optimization

Artificial intelligence analyzes data from the entire Breakfast Cereal production line—from raw material intake to energy consumption—to identify inefficiencies. Machine learning algorithms predict maintenance needs, optimize ingredient ratios, and even adjust extrusion parameters for new recipes, slashing energy use by 15-30%.These innovations prove that sustainability and productivity can coexist.

Future Trends in Breakfast Cereal Manufacturing

The Breakfast Cereal production line is poised for groundbreaking advancements, blending technology and sustainability to meet evolving consumer demands. Here’s a glimpse into the future:

1. 3D-Printed Cereal Shapes with Advanced Machines

Next-gen Breakfast Cereal Making Machines will leverage 3D printing to craft intricate shapes—think stars, animals, or custom logos—using nutrient-dense dough. This innovation allows brands to create engaging, kid-friendly designs or tailor textures for specific dietary needs (e.g., softer shapes for elderly consumers). The Breakfast Cereal process line will integrate real-time design updates, enabling on-the-fly customization without halting production.

2. Zero-Waste Production Models

Future Breakfast Cereal production lines will adopt circular economy principles. Grain husks and byproducts, once discarded, will be upcycled into biofuels or biodegradable packaging within the same facility. For instance, oat hulls could fuel boilers that power extrusion machines, closing the energy loop and eliminating landfill waste.

3. Personalized Nutrition via AI-Driven Enrichment

AI algorithms embedded in Breakfast Cereal Making Machines will analyze consumer health data (e.g., vitamin deficiencies) to enrich cereals during processing. Imagine a line that adds probiotics for gut health or iron for athletes—all in real time. This “nutrient-on-demand” approach will transform the Breakfast Cereal process line into a platform for hyper-targeted wellness solutions.

These trends promise to make breakfast cereals not just a meal, but a personalized, planet-friendly experience.

|

The Advantages of cereals snacks machine: |

|

|

1 |

Twin screw extruder for Cereal breakfast making machines adopts the extrusion technology. |

|

2 |

Extrusion equipment tends to have good continuous working performance and high production efficiency, thus reducing production costs. |

|

3 |

It can improve the textural characteristics, density and hydrophobicity of food materials, thus improving the taste and flavour of products, which is conducive to the refinement of coarse grains and makes them more acceptable to people. |

|

4 |

It can improve the textural characteristics, density and hydrophobicity of food materials, thus improving the taste and flavour of products, which is conducive to the refinement of coarse grains and makes them more acceptable to people. |

|

5 |

There is almost no waste during the production process, only a small amount of raw material is discharged during start-up and shutdown, thus reducing material waste. The extrusion process is a short process and the material is heated for a short period of time, thus preserving the maximum nutritional value of the material. |

Samples Of Breakfast Cereal Production Line

Breakfast cereals come in a variety of shapes, sizes, and colors to meet the taste preferences and visual appeal of different consumers.

Shape: Common ones include flakes (such as corn flakes), round particles (such as Cheerios), puffed balls (such as crispy rice balls), and innovative three-dimensional shapes (such as stars, animals, etc.). Modern technologies such as 3D printing can also customize personalized shapes, such as letters or brand logos.

Size: Usually between 0.5-3 cm in diameter, flake cereals are thinner (about 1-2 mm), and puffed ones are fluffy and light. Children's products are often designed to be small in size for easy grip; adult models may be larger and emphasize the chewing feel.

Color: Natural cereals are mostly beige, brown and other primary colors, but many products add natural pigments (such as beet red, spinach green, curcumin) to enhance visual appeal. For example, fruit-flavored cereals may be pink or purple, while chocolate flavored ones are dark brown. Under the health trend, "natural color" products without artificial colors are also becoming popular.

These characteristics not only affect the taste (such as crispier slices and softer puffed balls), but also stimulate appetite through color and shape, especially attracting children, while also fitting in with the brand differentiation strategy.

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/