Low cost, high returns! Energy-saving corn flake production line, excellent quality, guaranteed profit

Continuously Growing Global Corn Flakes Market

In recent years, with the rapid development of the snack food industry, corn chips have become a popular category in the global snack market due to their crispy texture, healthy ingredients, and diverse flavors. The crunch of each bite offers a satisfying auditory experience, while the blend of salt, spices, and sometimes even cheese, tantalizes taste buds. In Europe and America, corn chips are staple products for breakfast and snacks; they are often paired with creamy dips like guacamole or salsa, creating a perfect balance of textures and tastes. In Asia, the market for corn chips has seen explosive growth as young consumers increasingly seek convenient and healthy snacks. Brightly packaged and available in various flavors such as seaweed, wasabi, and sweet potato, these chips cater to local palates and dietary preferences, making them a hit among busy urban dwellers.

The corn flakes making machine has advanced snacks manufacturing process technology, combined with extruded snacks manufacturing process to develop and produce a fully automatic production line. This state-of-the-art machinery ensures high efficiency and precision, from the initial mixing of ingredients to the final packaging of the corn flakes. The corn flakes technology team has solved the existing small corn flakes making machine's difficult problems such as low output, low forming rate of corn flakes and poor taste of corn flakes, resulting in a product that is both delicious and visually appealing. The machine's sophisticated sensors and automated controls ensure that each batch of corn flakes is consistently crisp and golden brown, with a delightful crunch that delights consumers. The aroma of freshly made corn flakes wafts through the production facility, creating an inviting atmosphere. The high-speed extrusion process allows for the creation of various shapes and sizes, catering to diverse consumer preferences. Additionally, the machine's precise temperature control guarantees optimal cooking conditions, enhancing the natural sweetness of the corn and ensuring a rich, satisfying flavor profile. The packaging line is designed to maintain freshness, using airtight seals and moisture-resistant materials to keep the corn flakes crispy until the last bite.

The corn flakes production line takes various kinds of cereals as the basic raw material, including but not limited to maize, wheat, and rice. These cereals are carefully selected and processed to ensure optimal texture and flavor. The golden hue of the maize, the nutty aroma of wheat, and the subtle sweetness of rice contribute to a rich and varied sensory profile. The maize kernels are meticulously cleaned and pre-cooked to achieve the perfect balance of crispness and softness. Wheat grains are toasted to bring out their full-bodied flavor, while rice is steamed to maintain its natural sweetness and delicate texture. Additionally, the production line can also add various trace elements and food additives such as cocoa powder and powdered sugar according to the needs of corn flakes manufacturers, allowing for customization to meet diverse consumer preferences. The rich aroma of cocoa and the sweet crunch of powdered sugar enhance the overall sensory experience of the corn flakes, creating a delightful combination that appeals to both children and adults alike.

The hot selling low price corn flakes production line is suitable for all kinds of maize flakes, from light and crispy varieties to denser, more chewy options. This versatility makes it an ideal solution for manufacturers looking to diversify their product range. The light and crispy varieties offer a satisfying crunch with each bite, reminiscent of a gentle crackling sound, while the denser, chewier options provide a more substantial texture that can be enjoyed as a hearty snack or part of a nutritious meal. This versatility makes it an ideal solution for manufacturers looking to cater to different tastes and dietary needs. The production line produces products for various maize flakes fields, catering to both traditional breakfast cereals and innovative snack formats. It is the first choice of corn flakes making machine for major food manufacturers to expand the market, offering a reliable and scalable solution for meeting growing demand. The sleek design and user-friendly interface of the machinery further enhance its appeal, ensuring ease of operation and maintenance. This cutting-edge technology not only boosts productivity but also elevates the quality of the final product, making it a preferred choice for discerning consumers worldwide.

Comparison between traditional production lines and energy-saving cornflake production lines

|

traditional production lines |

energy-saving corn flake production lines |

|

✅ High energy consumption: Traditional cornflake production lines rely on high-temperature baking and prolonged oil frying, leading to high electricity and gas costs. |

✅ Reduce energy consumption by over 30%—using heat recovery technology to minimize energy waste. |

|

✅ High raw material waste: Inconsistent moisture and temperature control during processing results in low yield rates. |

✅ Compress production costs by 20%-40%—improving yield rates and reducing raw material losses. |

|

✅ High dependence on manual labor: Some stages still require manual operation, reducing production efficiency and increasing labor costs. |

✅ Increase capacity by 50%—with fully automated assembly lines, 24-hour continuous production to meet market demand. |

Core advantages of the product—low cost, high returns, energy-efficient and high performance.

- Low investment, quick return on investment In the corn flake production industry, the high investment of traditional equipment, often in the millions, deters many small and medium-sized enterprises. Our energy-saving corn flake production line stands out with its high cost-performance ratio, significantly lowering entry barriers: • Equipment price reduced by 30%: Through optimized design and mass production, customers can obtain advanced equipment at a lower initial investment.

• High level of automation, reducing reliance on manual labor: From raw material mixing, sheet forming, to baking and packaging, the entire process is fully automated, requiring only 2-3 operators per shift, saving over 50% in labor costs.

• Quick return on investment within 3-6 months: Taking a mid-sized production line as an example, with an average daily output of 5 tons, the investment can be recovered in less than six months, truly achieving 'low investment, fast returns'.

- Energy saving and consumption reduction, lowest operating costs in the industry Energy costs are the main expenditure in corn flake production. Our production line achieves an energy revolution through three innovations:

✔ Smart temperature control system

• Uses PID precise temperature control technology, keeping temperature fluctuations within ±1℃, saving 25% more energy compared to traditional equipment.

• Design for heat air circulation reuse, increasing thermal efficiency by 40%, saving over 150,000 yuan in gas fees annually just in the drying stage.

✔ Efficient low-consumption power system

• All motors meet IE4 ultra-high efficiency standards, saving 30% more electricity compared to ordinary motors.

• Innovative 'variable frequency drive' technology automatically adjusts power during low-load operation, avoiding no-load losses.

✔ Zero waste production model

• Equipped with real-time moisture monitoring instruments, raw material utilization rate reaches 99.2%, 8% higher than the industry average.

• Automatic recycling system for scrap materials, which can be reprocessed into corn flour, achieving zero waste of raw materials.

- High-quality production, quality assurance for guaranteed profits While controlling costs, we ensure that product quality meets international standards:

★ All parts in contact with food are made of 304 stainless steel, meeting FDA/CE certification.

★ Dual quality monitoring system

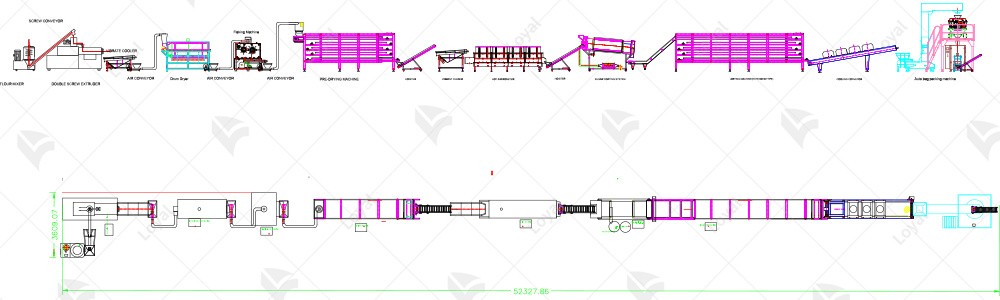

The main equipment functions of the corn flakes production line

1.Mixer of corn flakes production line: Mixing various raw materials with a motor-driven stirring cage, automatic water adding device, and pneumatic discharge valve, ensuring uniform, quick, and leak-proof mixing. The mixer's robust construction and precise controls guarantee consistent texture and flavor, with the aroma of fresh corn filling the air as the ingredients blend seamlessly.

2. Corn flakes making machine (Twin-screw extruder): Extrudes the raw materials through a precisely engineered mold to produce corn flakes or other foods of the desired shape and size. This machine features a sophisticated feeding system, an advanced extrusion system, a highly accurate cutting system, and a state-of-the-art heating system, ensuring optimal consistency and quality, with the sound of the extruder humming steadily and the scent of freshly cooked corn wafting through the air.

3. Tablet press of corn flakes making machine: The puffed corn kernels are pressed into corn flakes using a motor-driven mechanism that rotates two pressing rollers in opposite directions. The speed of the pressing rollers is adjustable, allowing for fine-tuning to achieve the perfect flake thickness and density, creating a satisfying crunch as each flake is formed.

4. Special Corn Flakes Making Machine Dryer: Puffed food contains a certain amount of moisture. During the drying process, the heating source can be electricity, gas, steam, or fuel, providing flexibility and efficiency. The dryer ensures that the moisture content is reduced to the ideal level, preserving the crispness and freshness of the corn flakes, with the gentle hiss of steam and the subtle aroma of dried corn permeating the environment.

2.Industrial Air Dryer: A high-pressure blower sprays hot air to make corn flakes instantly puffed and foamed, enhancing their texture and crispiness. The product becomes significantly more crispy after undergoing hot air baking, resulting in a delightful crunch with every bite, accompanied by the warm, inviting scent of freshly baked corn flakes.

3.Seasoning machine of corn flakes manufacturing machine: Used to season the food, this machine incorporates precise dosing mechanisms and mixing systems to ensure that the final product tastes delicious and has a well-balanced flavor profile, with the tantalizing aroma of spices and salt blending harmoniously with the natural sweetness of the corn.

7. Packaging machine of maize flakes making machine: This machine is designed to handle the final packaging of the produced food, ensuring it is securely sealed and ready for distribution and sale. Each piece of equipment in the corn flakes production line has its own unique advantages and works seamlessly together to enable 24-hour continuous production, resulting in higher quality corn flakes. The corn flakes making machine manufacturers have developed various models and specifications tailored to different needs and will also provide customized corn flakes plant equipment services, allowing more food processing plants to acquire the most suitable production line

|

Different model for sale of corn flakes making machine |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

LY65 |

222kw |

155kw |

100-150g/h |

39000x1200x2200mm |

|

LY70L |

326kw |

228kw |

200-250kg/h |

41000x1500x2200mm |

|

LY85 |

433kw |

303kw |

300-500kg/h |

43000x3500x4300mm |

|

LY75 |

583kw |

437kw |

300-500kg/h |

52000*2000*2800 |

|

LY95 |

740kw |

555kw |

800-1000kg/h |

56200*3000*2800 |

The Advantages of Corn Flakes Production Line:

|

●Twin screw extruder adopts frequency speed controlling with high automatic and stable pre-formtion, ensuring consistent quality and efficiency in the production process. |

|

●The screw of twin screw extruder are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer, providing robust performance over extended periods. |

|

●The forced lubrication system of twin screw extruder can guarantee the equipment transmission life longer, reducing maintenance needs and downtime. |

|

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise, allowing for meticulous adjustments and optimal conditions during extrusion. |

|

●Self-cleaning, when stopping, it can be cleaned without disassembling, simplifying maintenance and hygiene protocols. |

|

●Twin screw extruder systems efficiently produce a vast range of cereal flakes that meet an evolving demand for consumption at breakfast or snack, offering versatility in product offerings. Twin screw extrusion lines are simpler and more cost-effective compared with batch cooking systems traditionally used for flakes manufacturing, making them an attractive option for modern food producers. |

|

●Corn Flakes Making Process: More Flexible And More Cost-Effective, enabling manufacturers to adapt quickly to market trends and consumer preferences while maintaining profitability. |

Sample

The industrial corn flake making machine utilizes a twin screw extruder to produce corn flakes cereals, a nutritious and convenient food item crafted through the corn flakes manufacturing process. This sophisticated machinery ensures uniformity and consistency in the texture and size of the flakes. The primary ingredient for corn flakes is grist, which can be transformed into various shapes such as granules, flakes, and even whimsical animal-shaped pieces, appealing to both children and adults alike. A standout feature of corn flakes is their rich content of complex carbohydrates and dietary fiber, which aid in digestion and sustained energy release. Additionally, they are packed with a plethora of essential micronutrients including vitamins B and E, iron, and magnesium, contributing to overall health and well-being. The golden-brown flakes, often infused with a subtle sweetness from natural sources like honey or evaporated cane juice, provide a satisfying crunch and a wholesome start to the day. Their crisp texture and delightful flavor make them a beloved breakfast staple worldwide, enjoyed with milk, yogurt, or even as a base for creative culinary creations.

For more information, please visit the Facebook page:

https://www.facebook.com/Foodextruderfactory