Nutrition Bars Making Machine

Nutrition bar manufacturing equipment is used to mix ingredients, extrude the mixture at a set temperature, cool the product before cutting it to size, coating it, and allowing it to cool to prepare it for packaging. This Nutrition Bars Making Machine can produce protein bar, snickers bar, candy bar, nougat candy, cereal bar, and so on. Nutrition Bar Process Line The Nutrition Bar Process Line offers an all-in-one solution for creating high-quality, nutrient-dense bars with minimal energy consumption. This fully automatic line is designed to streamline production, from raw ingredient processing to final packaging, making it an ideal choice for manufacturers focused on efficiency and sustainability.

Nutrition Bar Production Process

Sugar Melt ---Mixing Material --Shaping-(Coating )-Packing

1.Sugar boiled pot: melting the sugar

2.Mixing machine:mixing the raw material

3.Hoister: to convey the material

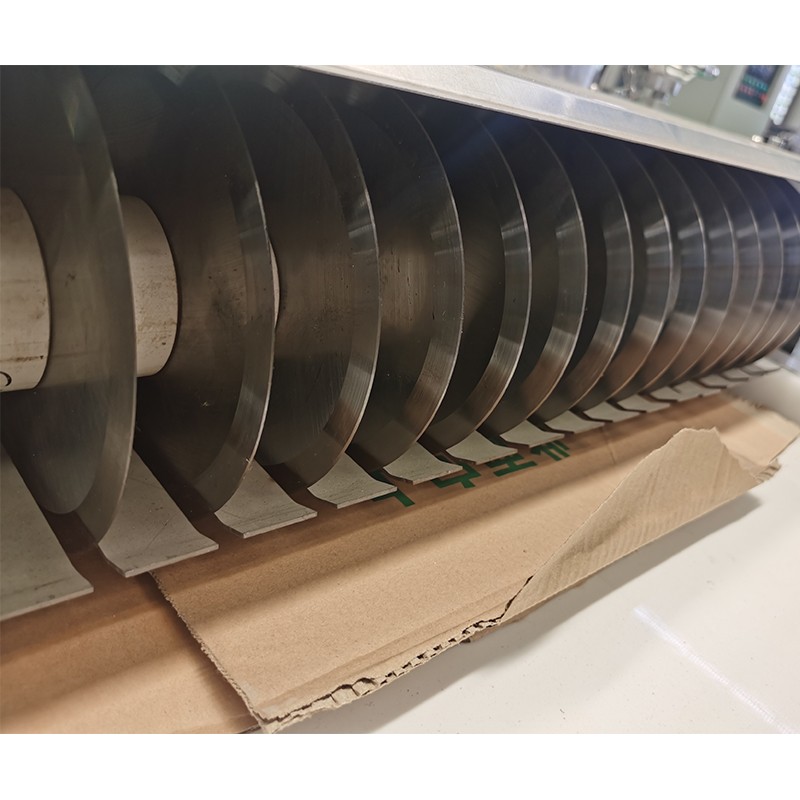

4.Automatic cereals bar cutting machine: shaping and cutting

5.Packaging machine: to package

The Main Features of Nutrition Bars Making Machine

|

Feature |

1.candy machine cooling system |

|

2.good cooling effect |

|

|

3.big output |

|

|

4.PLC screen touch control |

|

|

5.easy operation |

|

|

6.smooth work |

The Detail Descriptions Of The Nutrition Bars Making Machine

|

No. |

Item |

Detail descriptions |

|

1 |

Raw materials |

Sugar, corn flour, rice flour, peanut butter, nuts and so on. |

|

2 |

Consumption |

Low power and labor consumption |

|

3 |

Capacity |

100-300kg/h, 200-450kg/h, 400-600kg/h |

|

4 |

Machine material |

Stainless steel |

|

5 |

Products |

This line can produce protein bar, snickers bar, candy bar, nougat candy, cereal bar, and so on. |

Performance And Other Instructions

A. The food contact location is made of stainless steel 304 material, which meets the food QS and pharmaceutical GMP hygiene requirements.

B. Double frequency conversion system control, bag length is set and cut immediately, saving time and film.

C. High-sensitivity electric eye automatic tracking, no need to manually adjust after setting, sealing and cutting size, accurate position, strong and beautiful sealing.

D. Temperature independent PID intelligent control, stable temperature control, better suitable for various packaging materials.

Sample

The Nutrition Bar Process Line ensures each bar maintains optimal nutritional value, supporting health-conscious consumers while achieving high productivity. This efficient setup not only minimizes waste but also maintains consistency and quality in every batch, establishing a reliable and premium standard in the nutrition bar industry.

For more information, please visit the Facebook page:https://www.facebook.com/Foodextruderfactory