The Ultimate breakfast cereal manufacturers Guide to 2024

Introduction to Breakfast Cereal Manufacturing

Breakfast cereal manufacturing is a complex process that involves several stages to produce the familiar cereals found on store shelves. Manufacturers in this industry specialize in creating a variety of breakfast cereals to meet consumer demand for nutritious and convenient breakfast options. The production of breakfast cereals typically begins with the selection and processing of key ingredients such as grains, sugars, and flavorings. These ingredients are carefully measured and mixed according to specific recipes to ensure consistency and quality in the final product.

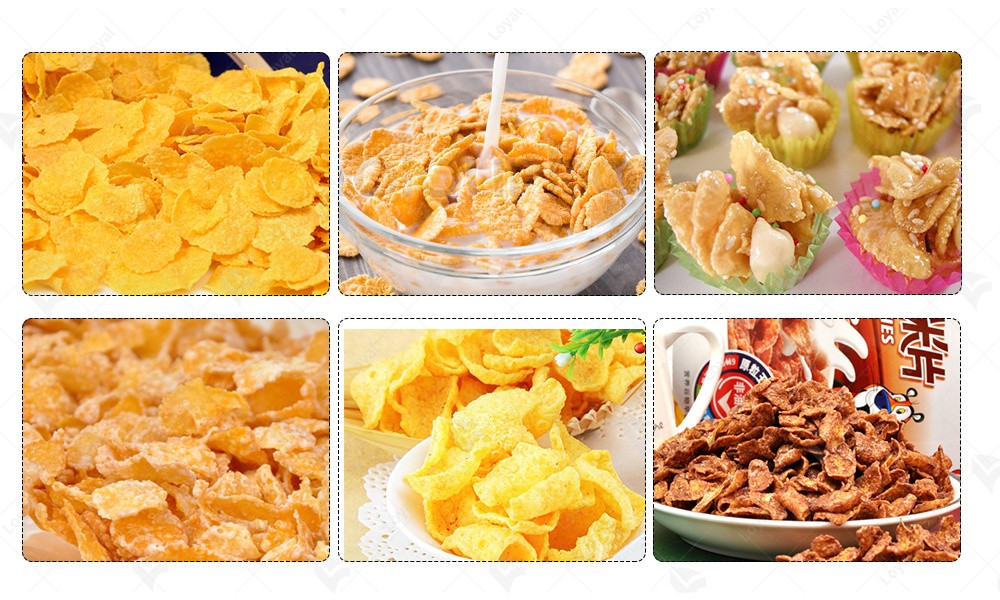

The manufacturing process then moves into cooking and shaping the cereal mixture into the desired forms, such as flakes, puffs, or clusters. This step often involves using industrial food machinery like cookers, extruders, and molders, which are crucial for achieving the correct texture and shape of the cereals. Once shaped, the cereals undergo drying or toasting to remove moisture and enhance flavor. This stage is critical for ensuring the cereals have the right crunch and taste that consumers expect.

Quality control plays a pivotal role throughout breakfast cereal manufacturing to maintain high standards and meet regulatory requirements. Manufacturers employ stringent testing procedures to monitor factors like taste, texture, nutritional content, and shelf life. This ensures that every batch of cereal leaving the production line meets safety and quality standards before reaching consumers. Breakfast cereal manufacturers also prioritize packaging innovations that preserve freshness and appeal to consumers while considering sustainability practices to reduce environmental impact.

Breakfast cereal manufacturing is a dynamic sector within the industrial food machinery industry, driven by innovation and consumer demand for nutritious breakfast options. By understanding the intricacies of ingredient selection, processing techniques, and quality assurance, manufacturers can continue to meet market demands while adapting to changing consumer preferences and regulatory requirements.

History and Evolution of Breakfast Cereal Production

Breakfast cereal manufacturing has a rich history that traces back to the late 19th century. Initially, breakfast cereals were developed as health foods to address dietary concerns and promote wellness among the population. The concept gained popularity in the United States and Europe during the Industrial Revolution, where advancements in food processing technology allowed for the mass production of cereals. Manufacturers like Kellogg's and General Mills played pivotal roles in shaping the industry, introducing iconic brands that have become household names worldwide.

The evolution of breakfast cereal production saw significant shifts in ingredients and manufacturing processes. Early cereals were often based on grains like wheat, oats, and corn, processed into flakes or granules. Over time, manufacturers diversified their product lines to include various flavors, textures, and nutritional profiles, catering to changing consumer preferences and dietary trends. Innovations in machinery, such as automated packaging systems and precision mixing technologies, further revolutionized the efficiency and scale of production.

Today, breakfast cereal manufacturers employ sophisticated equipment and stringent quality control measures to ensure consistency and safety in their products. Modern production facilities integrate advanced technologies that enhance productivity while minimizing environmental impact. The industry continues to innovate, with a focus on sustainability and nutritional enhancement, reflecting evolving consumer demands and regulatory standards.

The history and evolution of breakfast cereal production underscore its transformation from a niche health food to a global industry. Breakfast cereal manufacturers have continually adapted to technological advancements and consumer preferences, shaping the market dynamics and nutritional landscape of the modern food industry.

Types of Breakfast Cereal Products

|

Type of Breakfast Cereal Product |

Description |

|

Flakes |

Thin, flat pieces made from cooked grains such as corn, wheat, or oats, often toasted or baked. |

|

Puffs |

Light, airy cereal made from grains that are expanded under high pressure and then toasted. |

|

Granola |

Mixture of oats, nuts, seeds, and dried fruits baked until crispy, often served with yogurt or milk. |

|

Muesli |

Raw or toasted mixture of oats, nuts, seeds, and dried fruits, often eaten with milk or yogurt. |

|

Oatmeal |

Ground oats cooked into a porridge consistency, sometimes flavored with fruits or sweeteners. |

|

Wheat-based Cereals |

Cereals primarily made from wheat, such as shredded wheat or wheat biscuits. |

|

Rice-based Cereals |

Cereals made from rice, usually puffed or shaped into crisped rice forms. |

|

Corn-based Cereals |

Cereals made from corn, including corn flakes and corn puffs, often sweetened or flavored. |

|

Multi-grain Cereals |

Cereals that combine various grains like oats, wheat, corn, and barley for a diverse texture. |

|

High-fiber or Low-sugar Cereals |

Cereals specifically formulated with high fiber content or reduced sugar levels for health-conscious consumers. |

Market Trends in the Breakfast Cereal Industry

The breakfast cereal industry is experiencing dynamic shifts in consumer preferences and market dynamics. Manufacturers in the breakfast cereal sector are witnessing significant trends that shape their strategies and operations. Consumer demand for healthier breakfast options has been a predominant trend, prompting breakfast cereal manufacturers to innovate with low-sugar, high-fiber, and whole-grain varieties. This trend reflects a broader societal shift towards health-conscious eating habits, influencing product development and marketing strategies within the industry.

Technological advancements in manufacturing processes have also contributed to the market trends in the breakfast cereal industry. Automation and advanced machinery enable manufacturers to enhance production efficiency while maintaining product quality. This technological integration not only improves operational capabilities but also allows manufacturers to respond more swiftly to changing consumer preferences and market demands. As breakfast cereal manufacturers strive to meet these evolving trends, collaborations and partnerships with suppliers of industrial food machinery become crucial to adopting new technologies that support innovation and efficiency.

Furthermore, the global market for breakfast cereals continues to expand, driven by increasing urbanization and changing dietary patterns worldwide. Emerging markets, particularly in Asia-Pacific and Latin America, present substantial growth opportunities for breakfast cereal manufacturers. These regions exhibit rising disposable incomes and a growing appetite for convenience foods, creating a fertile ground for market expansion. Breakfast cereal manufacturers are keenly observing these regional trends and adapting their product offerings and marketing strategies to capitalize on the burgeoning consumer base.

Market trends in the breakfast cereal industry underscore the importance of innovation, health consciousness, and global market expansion. Breakfast cereal manufacturers must navigate these trends strategically, leveraging technological advancements and consumer insights to maintain competitiveness and sustain growth in a dynamic marketplace. By aligning with these evolving trends, manufacturers can position themselves effectively in the competitive landscape of the breakfast cereal industry.

Key Ingredients Used in Breakfast Cereal Production

|

Ingredient |

Purpose in Production |

|

Whole Grains |

Provide fiber, texture, and nutritional value. |

|

Sugar |

Enhance flavor and sweetness. |

|

Salt |

Flavor enhancement and preservation. |

|

Vegetable Oils |

Aid in cooking and provide texture. |

|

Vitamins & Minerals |

Fortify nutritional profile. |

|

Flavorings |

Add taste diversity and appeal. |

|

Preservatives |

Extend shelf life and maintain freshness. |

|

Emulsifiers |

Ensure uniform texture and stability in the product. |

|

Coloring Agents |

Enhance visual appeal and brand identity. |

|

Nuts and Seeds |

Add crunch, flavor variation, and nutritional value. |

Breakfast Cereal Manufacturing Processes

Breakfast cereal manufacturers employ several key processes to transform raw ingredients into finished products. First, the raw grains such as corn, wheat, oats, or rice are cleaned and inspected for quality. Next, they undergo milling, where they are ground into flour or meal. This step is crucial as it determines the texture and consistency of the final cereal product. Subsequently, the milled grains are mixed with water, sugar, flavorings, and often vitamins and minerals in precise ratios.

The mixed ingredients are then cooked using various methods such as extrusion, baking, or flaking, depending on the type of cereal being produced. Extrusion involves forcing the cereal dough through a shaped opening, resulting in different shapes like flakes or loops. Baking is used for granola-type cereals, where the mixture is baked until crispy. Flaking processes involve pressing cooked grains into flakes, which are then toasted to enhance flavor and texture. Finally, the cereals are dried to remove moisture, cooled, and packaged for distribution to consumers.

Breakfast cereal manufacturing processes are complex and require precise control over ingredients and techniques. These processes ensure that the final products meet quality standards and provide nutritional benefits. Manufacturers continuously innovate to meet consumer demand for diverse cereal options while adhering to stringent production standards.

Quality Control and Assurance in Breakfast Cereal Manufacturing

Quality control and assurance play critical roles in ensuring that breakfast cereal manufacturers maintain high standards throughout their production processes. Effective quality control begins with stringent checks on raw materials sourced for cereal production. Manufacturers must verify the quality and consistency of ingredients like grains, sugars, flavorings, and additives to meet both regulatory standards and consumer expectations. This initial phase sets the foundation for the entire manufacturing process, aiming to prevent issues before they arise.

During production, quality assurance procedures involve continuous monitoring and testing at various stages. This includes regular inspections of equipment functionality and cleanliness to prevent contamination and ensure product safety. Each batch undergoes meticulous testing for taste, texture, nutritional content, and shelf-life stability. These measures not only uphold quality but also contribute to the consistent taste and texture expected by consumers.

Moreover, packaging is a critical stage where quality control ensures that finished products are sealed securely and labeled accurately. Packaging materials must meet food safety regulations and protect the cereal from external factors like moisture and light. Final inspections are conducted to verify that each box or bag of cereal meets visual and functional standards before distribution.

Quality control and assurance in breakfast cereal manufacturing are indispensable processes that uphold product integrity and consumer trust. By implementing robust quality management systems from ingredient sourcing to final packaging, manufacturers can maintain high standards and deliver safe, consistent products to consumers worldwide.

Packaging and Distribution Strategies for Breakfast Cereal Products

Packaging and distribution strategies play a crucial role in the breakfast cereal manufacturing industry, ensuring that products reach consumers in optimal condition. Manufacturers of breakfast cereal products prioritize effective packaging solutions that maintain product freshness and appeal on store shelves. Additionally, sustainable packaging practices are increasingly emphasized to align with consumer preferences for eco-friendly options. Distribution channels are carefully selected to efficiently transport breakfast cereal products from manufacturing facilities to retail outlets nationwide. This includes leveraging logistics networks to minimize transportation costs and ensure timely delivery to retailers.

Moreover, breakfast cereal manufacturers often collaborate with packaging experts to innovate designs that enhance product visibility and consumer engagement. Strategic placement in supermarkets and grocery stores is key to maximizing product visibility and accessibility to target consumers. Digital marketing strategies complement traditional distribution methods, utilizing online platforms to promote new product launches and engage with consumers directly. By implementing these packaging and distribution strategies, breakfast cereal manufacturers can effectively meet consumer demand while maintaining competitive advantage in the market.

Sustainability Practices in Breakfast Cereal Manufacturing

Sustainability practices in breakfast cereal manufacturing play a crucial role in addressing environmental impacts and meeting consumer expectations for eco-friendly products. Manufacturers are increasingly adopting sustainable sourcing strategies to reduce their carbon footprint and promote environmental stewardship. This includes sourcing ingredients from sustainable farms and ensuring responsible agricultural practices throughout the supply chain. By partnering with certified suppliers, breakfast cereal manufacturers can ensure that raw materials like grains and fruits are grown without harmful chemicals or excessive water usage, thus preserving natural resources for future generations.

Implementing efficient manufacturing processes is another key aspect of sustainability in the breakfast cereal industry. Manufacturers invest in energy-efficient equipment and technologies to minimize energy consumption and greenhouse gas emissions during production. This includes optimizing packaging materials to reduce waste and using renewable energy sources to power manufacturing facilities. By embracing these practices, breakfast cereal manufacturers not only reduce their environmental impact but also enhance operational efficiency and cost-effectiveness, contributing to long-term sustainability goals.

Moreover, sustainable packaging solutions are integral to reducing the environmental footprint of breakfast cereal products. Manufacturers are transitioning towards recyclable, biodegradable, or compostable packaging materials to minimize plastic waste and promote circular economy principles. By adopting packaging designs that prioritize sustainability without compromising product quality or shelf life, manufacturers can meet consumer demand for environmentally friendly choices while ensuring compliance with regulatory requirements.

In conclusion, sustainability practices in breakfast cereal manufacturing encompass a holistic approach that integrates sustainable sourcing, efficient production processes, and eco-friendly packaging solutions. By prioritizing environmental stewardship and operational efficiency, manufacturers can enhance their competitiveness in the market while meeting consumer expectations for sustainable products. Adopting these practices not only benefits the environment but also strengthens brand reputation and supports long-term business sustainability.

References

1.Food Processing Technology - www.foodprocessing-technology.com

2.Food Engineering Magazine - www.foodengineeringmag.com

3.ProFood World - www.profoodworld.com

4.Food Manufacturing - www.foodmanufacturing.com

5.International Society of Automation (ISA) - www.isa.org