Everything You Need to Know About Twin Screw Extruder Panko Breadcrumbs Machines

Introduction to Twin Screw Extruder Technology

Twin Screw Extruder Panko Breadcrumbs Machines represent a pinnacle in modern food processing technology. These machines utilize twin screw extruder technology, which revolutionizes the efficiency and precision of food production processes. Unlike single screw extruders, twin screw extruders employ two intermeshing screws within a tightly controlled barrel. This design facilitates superior mixing, kneading, and shearing of food materials, ensuring uniformity in texture and consistency of products such as Panko breadcrumbs.

The versatility of twin screw extruders extends beyond basic mixing; they can handle a wide range of ingredients, from fine flours to coarse grains, effortlessly adjusting parameters to achieve desired product specifications. This makes them indispensable in the food industry, where consistency and quality are paramount.

In industrial settings, Twin Screw Extruder Panko Breadcrumbs Machines are engineered with robust components that withstand high operational pressures and temperatures, meeting stringent food safety standards while maximizing throughput and minimizing downtime.

Overview of Panko Breadcrumbs Production

Panko breadcrumbs have gained worldwide popularity for their light, airy texture and superior crunchiness compared to traditional breadcrumbs. The production process begins with selecting high-quality ingredients such as flour, water, and yeast, which are precisely mixed in the twin screw extruder.

The twin screw extruder plays a crucial role in this process by precisely controlling the dough's consistency and texture through its adjustable screw configuration and barrel temperature zones. This ensures the formation of uniform dough sheets that are subsequently processed into thin ribbons and cut into desired breadcrumb shapes.

After forming, the breadcrumbs undergo a specialized drying process to achieve their characteristic lightness and texture. The twin screw extruder’s efficient heat transfer mechanisms enable rapid moisture removal while maintaining product integrity, resulting in breadcrumbs with optimal moisture content and extended shelf life.

Once dried, the breadcrumbs are toasted to a golden brown color, imparting a rich flavor profile and ensuring crispiness upon frying or baking. This final step in Panko breadcrumbs production showcases the precision and reliability of twin screw extruder technology in achieving consistent product quality demanded by discerning consumers and food manufacturers alike.

Key Features of Twin Screw Extruders

Twin Screw Extruders are engineered with a robust set of features that ensure optimal performance and versatility in food production settings. Here are the key features highlighted:

|

Feature |

Description |

|

Twin Screw Configuration |

The dual screws facilitate thorough mixing, precise temperature control, and enhanced throughput, crucial for consistent breadcrumb production. |

|

Modular Barrel Design |

Allows for easy adaptation to varying recipes and production needs, ensuring flexibility without compromising efficiency. |

|

Advanced Control Systems |

Incorporates PLC systems for precise process control, enabling operators to maintain quality and consistency across batches. |

|

Integrated Cooling Systems |

Efficient cooling mechanisms prevent overheating during extended operation, prolonging machine lifespan and maintaining product integrity. |

|

High-Quality Construction Materials |

Utilizes stainless steel and food-grade materials to meet hygiene standards and ensure durability, essential for food safety and long-term reliability. |

Benefits of Using Twin Screw Extruders

Twin Screw Extruder machines revolutionize the production of Panko breadcrumbs in the food processing industry. These extruders offer superior performance and efficiency compared to traditional single-screw alternatives.

Firstly, Twin Screw Extruders enhance throughput significantly. Their dual-screw design enables higher production rates, meeting the growing demand for Panko breadcrumbs without compromising quality.

Secondly, these machines ensure precise control over the extrusion process. Manufacturers can adjust parameters such as temperature, pressure, and screw speed to achieve the desired texture and consistency of Panko breadcrumbs consistently.

Moreover, Twin Screw Extruders are renowned for their versatility. They can handle a wide range of ingredients and formulations, making them suitable for various Panko breadcrumb recipes, from plain to flavored variants.

Lastly, maintenance of Twin Screw Extruders is relatively straightforward compared to older models. Modern designs prioritize easy access for cleaning and servicing, minimizing downtime and optimizing operational efficiency.

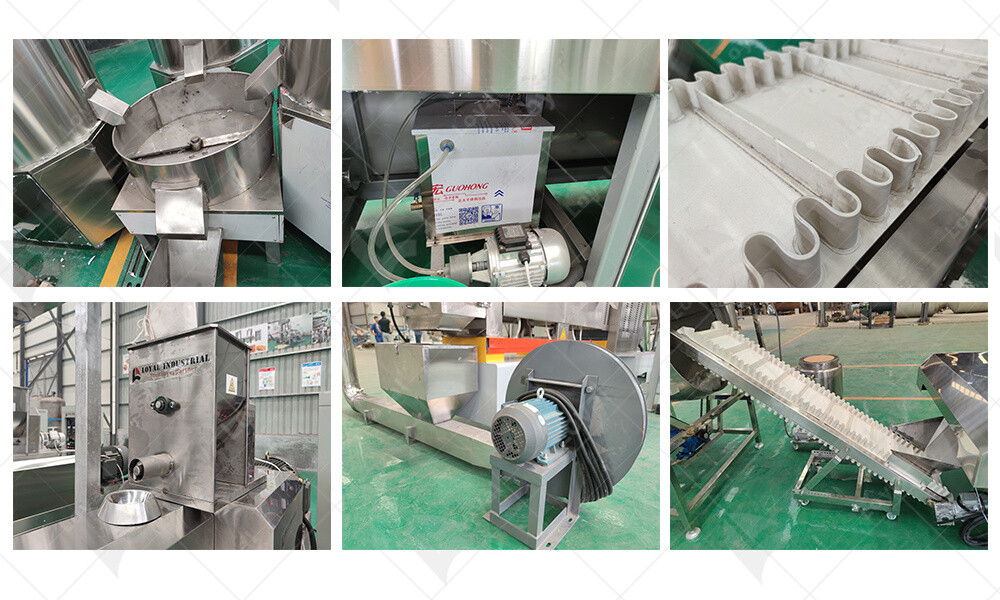

Essential Components of Panko Breadcrumbs Machines

Modern Twin Screw Extruder Panko Breadcrumbs Machines are sophisticated pieces of equipment designed to efficiently and precisely produce high-quality panko breadcrumbs. These machines consist of several essential components that work in tandem to achieve consistent results:

|

Component |

Description |

|

Twin Screw Extruder |

The heart of the machine, where the mixing, kneading, and extrusion processes occur. It ensures thorough blending of ingredients and precise texture control. |

|

Feeding System |

Responsible for accurately metering ingredients into the extruder, maintaining a consistent flow to achieve uniform product density. |

|

Cutting Mechanism |

Cuts the extruded dough into desired breadcrumb shapes and sizes, crucial for the final texture and appearance of the panko. |

|

Drying Chamber |

Facilitates controlled drying of the breadcrumbs, optimizing moisture removal to achieve the characteristic light and crispy texture. |

|

Cooling System |

Rapidly cools the freshly baked breadcrumbs to prevent overcooking and maintain product integrity before packaging. |

Each component plays a vital role in the overall operation of the Twin Screw Extruder Panko Breadcrumbs Machine, ensuring efficiency and consistency from raw ingredients to finished product.

Applications of Panko Breadcrumbs in Food Industry

One of the primary applications of panko breadcrumbs is in the coating of fried foods. The use of Twin Screw Extruder Panko Breadcrumbs Machines ensures that the breadcrumbs have the desired texture, which is essential for achieving the perfect crunch in fried dishes. Whether it's chicken katsu, tempura, or breaded shrimp, panko breadcrumbs produced by these advanced machines provide a superior coating that enhances the overall eating experience.

Another significant application is in the baking industry. Panko breadcrumbs are often used as a topping for casseroles, gratins, and baked pasta dishes. The consistency provided by Twin Screw Extruder Panko Breadcrumbs Machines guarantees that the breadcrumbs offer a uniform texture and appearance, which is crucial for commercial baking operations. This uniformity not only improves the visual appeal of the baked goods but also ensures an even distribution of texture and flavor.

In the realm of food processing, panko breadcrumbs serve as an excellent filler and binder in products like meatballs, burgers, and sausages. The precise control offered by Twin Screw Extruder Panko Breadcrumbs Machines allows manufacturers to produce breadcrumbs with specific properties that enhance moisture retention and binding capabilities. This results in a final product that is both tender and cohesive, meeting the high standards of the food industry.

Lastly, panko breadcrumbs are increasingly being used in innovative culinary applications. Chefs and food manufacturers are exploring new ways to incorporate panko into their recipes, from using them as a crust for fish and seafood dishes to incorporating them into dessert toppings for added crunch. The versatility and high quality achieved through Twin Screw Extruder Panko Breadcrumbs Machines make panko breadcrumbs a valuable ingredient in a wide range of gastronomic creations.

Quality Control in Panko Production

Quality control is paramount in the production of panko breadcrumbs to meet rigorous industry standards and consumer expectations. The process involves several critical steps to maintain product quality and safety:

Raw Material Selection: High-quality raw materials, including flour and yeast, are carefully selected to ensure optimal dough consistency and flavor profile, essential for premium panko production.

Process Monitoring: Continuous monitoring of the extrusion and cutting processes ensures that the breadcrumbs meet specified dimensions and texture standards. Any deviations are promptly addressed to maintain consistency.

Drying Optimization: Precise control of the drying temperature and airflow in the drying chamber is crucial for achieving the desired panko texture—light, airy, and uniformly crispy—without compromising on quality.

Packaging and Storage: After cooling, panko breadcrumbs are meticulously packaged in a controlled environment to prevent moisture absorption and preserve freshness. Proper labeling and storage conditions further contribute to product longevity and consumer satisfaction.

By adhering to stringent quality control measures throughout the production cycle, manufacturers of Twin Screw Extruder Panko Breadcrumbs Machines ensure that their products consistently deliver superior texture, flavor, and functionality to culinary professionals worldwide.

Troubleshooting Common Issues

When working with Twin Screw Extruder Panko Breadcrumbs Machines, you may encounter a few common issues that can affect the efficiency and quality of the output. Below, we discuss some of these issues and their potential solutions:

Irregular Breadcrumb Texture: One of the most common issues is irregular breadcrumb texture. This can be caused by inconsistent feed rates or improper screw configuration.

Solution: Ensure the feed rate is consistent and appropriate for the desired texture. Regularly inspect and maintain the screw configuration to match the specific production requirements.

Overheating: Overheating of the extruder can lead to burnt breadcrumbs and equipment damage.

Solution: Regularly monitor the temperature settings and ensure cooling systems are functioning correctly. Implement preventive maintenance schedules to check for any wear and tear in the heating elements.

Blockages in the Extruder: Blockages can occur due to inadequate cleaning or improper ingredient mixture.

Solution: Implement thorough cleaning protocols after each production run. Ensure that the ingredient mix is compatible with the extruder specifications and free from contaminants.

Inconsistent Output: Variations in the size and shape of breadcrumbs can result from fluctuations in screw speed or pressure.

Solution: Calibrate the screw speed and pressure settings regularly. Use automated systems to maintain consistent production parameters.

Machine Downtime: Frequent machine downtimes can severely impact production schedules.

Solution: Establish a routine maintenance program to minimize unexpected downtimes. Keep a log of machine performance and address minor issues before they escalate into major problems.

Comparing Twin Screw and Single Screw Extruders

When selecting an extruder for panko breadcrumb production, it's essential to understand the differences between twin screw and single screw extruders. Below is a detailed comparison:

|

Feature |

Twin Screw Extruder |

Single Screw Extruder |

|

Mixing Efficiency |

High – Provides excellent mixing and shearing capabilities, ideal for complex recipes. |

Moderate – Less efficient in mixing and may require additional processing steps. |

|

Output Consistency |

High – Produces consistent size and texture of breadcrumbs. |

Variable – May result in inconsistent breadcrumb quality. |

|

Versatility |

High – Suitable for a wide range of ingredients and recipes. |

Moderate – Limited to simpler recipes and ingredient mixes. |

|

Processing Capacity |

High – Capable of handling large production volumes. |

Lower – Best suited for smaller scale productions. |

|

Energy Consumption |

Higher – Due to the dual screws and advanced features. |

Lower – Single screw systems consume less energy. |

|

Maintenance Requirements |

More complex – Requires regular maintenance and skilled operators. |

Simpler – Easier to maintain with less frequent servicing. |

|

Initial Investment |

Higher – More expensive due to advanced technology and capabilities. |

Lower – Cost-effective for basic production needs. |

|

Operational Flexibility |

High – Allows for quick adjustments and recipe changes. |

Limited – Less adaptable to changes in production requirements. |

|

Shearing and Heat Transfer |

Superior – Better shearing action and heat transfer, reducing processing time. |

Inferior – Limited shearing and heat transfer capabilities. |

|

Product Quality |

High – Produces high-quality breadcrumbs with uniform texture. |

Moderate – May produce varying product quality. |

Innovations in Twin Screw Extruder Design

In recent years, advancements in Twin Screw Extruder technology have revolutionized the production capabilities of Panko Breadcrumbs Machines in the food industry. These extruders, featuring dual intermeshing screws, now incorporate state-of-the-art innovations designed to enhance efficiency and product quality.

Modern Twin Screw Extruder Panko Breadcrumbs Machines integrate precision-controlled screw configurations. These configurations optimize the extrusion process, ensuring consistent particle size and texture in breadcrumb production. Manufacturers benefit from increased throughput rates without compromising on product uniformity, meeting the demands of high-volume production lines.

Moreover, the incorporation of advanced material handling systems in newer extruder models minimizes downtime due to material inconsistencies. This improvement ensures continuous operation, contributing to enhanced overall productivity and reduced operational costs for food processing facilities.

Furthermore, the latest generation of Twin Screw Extruder Panko Breadcrumbs Machines incorporates robust cleaning and sanitation features. These advancements not only streamline the cleaning process but also ensure compliance with stringent hygiene standards in food manufacturing environments. Manufacturers can now achieve superior cleanliness levels, safeguarding product integrity and consumer safety.

Maintenance Tips for Extruder Machines

Effective maintenance practices are crucial for maximizing the lifespan and performance of Twin Screw Extruder Panko Breadcrumbs Machines. Routine inspection and upkeep of critical components such as screws and barrels are essential to prevent wear and optimize extrusion efficiency.

Regular lubrication of the extruder's mechanical parts is paramount to reduce friction and extend component longevity. Utilizing high-quality lubricants formulated for food-grade machinery ensures smooth operation while maintaining product integrity.

Additionally, conducting periodic calibration checks on temperature and pressure controls is imperative. Precise control over these parameters ensures consistent product quality and prevents deviations in breadcrumb texture and appearance.

Moreover, proactive monitoring of electrical components and control systems helps mitigate the risk of unexpected downtime. Implementing a preventive maintenance schedule that includes comprehensive system diagnostics and component testing minimizes the likelihood of equipment failure during production runs.

By adhering to these maintenance guidelines, food manufacturers can uphold optimal performance levels of their Twin Screw Extruder Panko Breadcrumbs Machines. This proactive approach not only enhances operational efficiency but also supports sustained profitability and customer satisfaction in the competitive food processing industry.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com