Everything You Need to Know About Fully Automatic Bread Crumb Production Line Extruder

Introduction to Fully Automatic Bread Crumb Production Line Extruder

In the modern food industry, efficiency and consistency are paramount. The Fully automatic bread crumb production line extruder represents a pinnacle of innovation in food processing technology. This equipment not only ensures high-quality bread crumbs but also streamlines the production process, making it indispensable for large-scale manufacturing operations. The extruder automates each step, from mixing and baking to grinding, thereby reducing labor costs and increasing output.

The demand for bread crumbs in various culinary applications has led to advancements in production techniques. Traditional methods, while effective, are labor-intensive and lack uniformity. The fully automatic bread crumb production line extruder addresses these issues by providing a consistent and reliable solution. Its design incorporates cutting-edge technology to produce bread crumbs of uniform size and texture, meeting the stringent requirements of food manufacturers.

By integrating automation into the production line, this extruder significantly enhances productivity. Operators can achieve precise control over the process, ensuring that the final product meets the desired specifications. The fully automatic bread crumb production line extruder is thus a vital component for any business looking to scale up its operations while maintaining high quality standards.

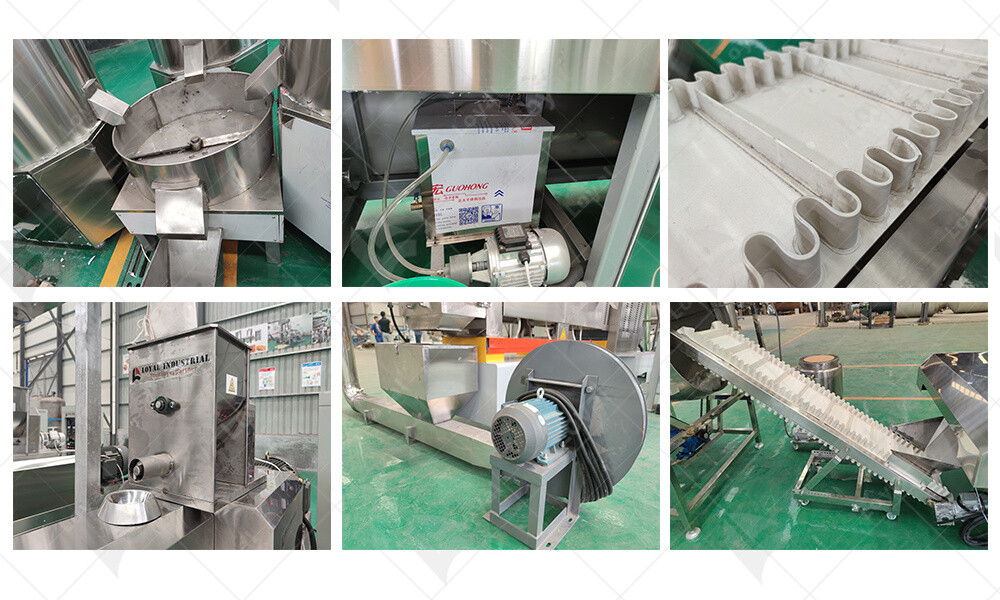

Key Components of Bread Crumb Production Lines

|

Component |

Description |

|

Mixing System |

The initial phase involves blending raw materials such as flour, yeast, and water. This system ensures a homogeneous mixture, essential for the subsequent stages. The mixing system in a fully automatic bread crumb production line extruder is designed for consistency and efficiency. |

|

Fermentation Unit |

After mixing, the dough undergoes controlled fermentation. This unit maintains optimal temperature and humidity levels, crucial for achieving the desired dough texture and flavor. The fully automatic bread crumb production line extruder ensures precise control for consistent results. |

|

Extrusion Machine |

The core component, where the dough is shaped into specific forms before baking. The fully automatic bread crumb production line extruder uses advanced technology to create uniform shapes, which are essential for producing high-quality bread crumbs. |

|

Baking Oven |

The extruded dough is baked to the perfect consistency. This oven ensures even baking through precise temperature control. The integration with the fully automatic bread crumb production line extruder ensures each piece is baked uniformly, which is critical for the final grinding process. |

|

Cooling Conveyor |

Post-baking, the products need to cool down before grinding. The cooling conveyor in a fully automatic bread crumb production line extruder ensures that the products reach the optimal temperature efficiently, preventing any alterations in texture or quality. |

|

Grinding and Sieving Unit |

This unit grinds the baked products into crumbs of desired sizes. The sieving process ensures uniform particle size, a hallmark of high-quality bread crumbs. The fully automatic bread crumb production line extruder allows for adjustable settings to meet specific customer requirements. |

|

Packaging System |

The final step involves packaging the bread crumbs. This system automates the packing process, ensuring that the product is sealed in airtight packages to maintain freshness. The packaging system of a fully automatic bread crumb production line extruder is designed for speed and accuracy. |

How Fully Automatic Systems Enhance Efficiency

Fully automatic bread crumb production line extruders significantly enhance efficiency in several ways. Firstly, fully automatic bread crumb production line extruder systems reduce the need for manual intervention, which minimizes human error and ensures consistent product quality. Automation also streamlines the production process, from ingredient mixing to final product packaging, leading to faster turnaround times and higher throughput.

Secondly, the integration of advanced control systems allows for real-time monitoring and adjustments. These systems can detect and rectify issues immediately, ensuring minimal downtime. The fully automatic bread crumb production line extruder is designed to operate continuously with minimal maintenance, further boosting overall efficiency.

Thirdly, these automated systems optimize resource usage. They precisely control ingredient quantities and energy consumption, reducing waste and operational costs. The efficiency gains from using a fully automatic bread crumb production line extruder translate to lower production costs and higher profitability.

Lastly, the scalability of fully automatic systems allows manufacturers to easily adjust production volumes in response to market demand. This flexibility ensures that the production line can meet varying consumer needs without compromising efficiency or quality.

Understanding the Extruder's Role in Production

The extruder is a critical component in the bread crumb production line. It performs several essential functions that ensure the production of high-quality bread crumbs. Below is a detailed table highlighting the key roles of the fully automatic bread crumb production line extruder:

|

Function |

Description |

Benefits |

|

Mixing |

The extruder thoroughly mixes all ingredients to create a uniform dough. |

Ensures consistency and homogeneity in the final product. |

|

Cooking |

It applies heat to cook the dough, transforming it into the desired texture and consistency. |

Provides precise control over cooking parameters, ensuring optimal texture. |

|

Shaping |

The dough is forced through a die to shape it into the required form. |

Allows for customization of crumb shapes to meet various market preferences. |

|

Cutting |

The extruder cuts the shaped dough into uniform pieces. |

Ensures uniformity in size, which is essential for consistent frying or baking. |

|

Drying |

It includes a drying stage to remove excess moisture from the crumbs. |

Enhances shelf-life and maintains product quality. |

The fully automatic bread crumb production line extruder integrates these functions into a seamless process, ensuring efficient and consistent production of bread crumbs. Its role is pivotal in transforming raw ingredients into a finished product that meets stringent quality standards.

By understanding the importance of the extruder in the production line, manufacturers can appreciate the technological advancements that make these systems indispensable in modern food production. The fully automatic bread crumb production line extruder not only enhances efficiency but also ensures the production of superior quality bread crumbs that cater to diverse consumer preferences.

Innovations in Bread Crumb Production Technology

In recent years, the fully automatic bread crumb production line extruder has revolutionized the food processing industry. This advanced machinery integrates cutting-edge technologies to enhance production efficiency, improve product quality, and ensure consistency. One significant innovation is the introduction of smart control systems, which allow operators to monitor and adjust the production process in real-time. This feature not only minimizes human error but also optimizes resource usage.

Moreover, the latest extruders are equipped with advanced temperature control mechanisms. These mechanisms ensure that the bread crumbs are processed at optimal temperatures, preserving their texture and nutritional value. Another notable innovation is the modular design of the fully automatic bread crumb production line extruder, which simplifies maintenance and allows for easy upgrades. This flexibility is crucial for manufacturers looking to adapt to changing market demands without significant downtime or investment.

Additionally, energy efficiency has become a focal point in the development of new bread crumb production technology. Modern extruders are designed to consume less power while maintaining high output levels, making them both economically and environmentally beneficial. These innovations collectively contribute to a more streamlined, reliable, and cost-effective production process, cementing the fully automatic bread crumb production line extruder as an essential tool in the food manufacturing sector.

Installation and Setup of Bread Crumb Production Lines

Setting up a fully automatic bread crumb production line extruder involves several critical steps to ensure optimal performance and safety. The following table outlines the detailed installation and setup process:

|

Step |

Description |

|

Site Preparation |

Ensure the installation site is clean, level, and has adequate ventilation. |

|

Utility Connections |

Connect the extruder to the appropriate power source, water supply, and drainage. |

|

Assembly |

Assemble the extruder components as per the manufacturer’s instructions. |

|

Calibration |

Calibrate the machine settings, including temperature and extrusion speed. |

|

Testing |

Conduct initial testing to verify that the machine operates correctly. |

|

Training |

Provide comprehensive training to operators on using and maintaining the extruder. |

Proper installation and setup are vital to maximize the efficiency and longevity of the fully automatic bread crumb production line extruder. Following these steps meticulously helps prevent potential issues and ensures smooth operation from the outset.

Maintenance Tips for Bread Crumb Extruders

To maintain the optimal performance and extend the lifespan of a fully automatic bread crumb production line extruder, regular maintenance is essential. The following table provides detailed maintenance tips:

|

Maintenance Task |

Frequency |

Description |

|

Cleaning |

After each use |

Thoroughly clean the extruder to prevent residue buildup, which can affect product quality. |

|

Lubrication |

Weekly |

Lubricate moving parts to reduce wear and tear and ensure smooth operation. |

|

Inspection |

Monthly |

Inspect all components for signs of wear, damage, or corrosion. Replace any faulty parts. |

|

Calibration Check |

Quarterly |

Check and recalibrate settings to maintain precision in production parameters. |

|

Software Updates |

As needed |

Ensure the extruder's software is up-to-date to benefit from the latest features and improvements. |

|

Safety Checks |

Monthly |

Verify that all safety mechanisms and emergency stops are functioning correctly. |

By adhering to these maintenance guidelines, operators can ensure that their fully automatic bread crumb production line extruder remains in top condition, thus avoiding costly downtimes and maintaining high production standards. Regular maintenance not only enhances performance but also contributes to the overall safety and efficiency of the production process.

Common Issues and Troubleshooting in Production Lines

One of the common issues encountered in a fully automatic bread crumb production line extruder is inconsistent product texture. This can often be traced back to variations in ingredient quality or improper mixing ratios. Regular calibration and maintenance of mixing equipment, as well as stringent quality checks on raw materials, can mitigate this issue.

Another frequent problem is the extruder jamming or clogging. This issue usually arises due to improper cleaning and maintenance or foreign objects entering the system. Implementing a rigorous cleaning schedule and installing effective filtration systems at input points can help prevent such occurrences.

Temperature control is crucial in the extrusion process. Overheating or underheating can lead to defective products. Ensuring that the fully automatic bread crumb production line extruder is equipped with accurate temperature sensors and a reliable cooling system can address this issue effectively.

Wear and tear of machine parts, particularly the extruder screw and barrel, is another common problem. Regular inspection and timely replacement of worn parts are essential to maintaining optimal performance. Using high-quality, durable materials for machine components can also prolong the lifespan of the equipment.

Safety Measures for Operating Bread Crumb Extruders

Safety is paramount when operating a fully automatic bread crumb production line extruder. One of the fundamental safety measures is to ensure all operators are adequately trained in the machine's operation, including understanding the control panel, emergency stop functions, and routine maintenance procedures.

Personal protective equipment (PPE) such as gloves, goggles, and protective clothing should always be worn to prevent injuries. This is particularly important during maintenance or troubleshooting activities where operators may come into contact with hot surfaces or sharp components.

Regular safety audits and checks should be conducted to identify potential hazards. This includes inspecting electrical systems for any signs of wear or damage, ensuring all safety guards are in place and functional, and checking that emergency stop buttons are easily accessible and operational.

Implementing a lockout/tagout (LOTO) procedure is crucial to ensure that the fully automatic bread crumb production line extruder is properly shut down and isolated from all energy sources before any maintenance or cleaning activities begin. This prevents accidental startup and reduces the risk of injury.

Environmental Impact of Bread Crumb Production Technology

The environmental impact of a fully automatic bread crumb production line extruder can be significant, primarily due to energy consumption and waste generation. To mitigate these impacts, it is essential to optimize energy usage through efficient machinery and process improvements. This includes using energy-efficient motors and implementing waste heat recovery systems.

Waste management is another critical aspect. The production process can generate by-products and waste that need to be properly managed to minimize environmental harm. Implementing recycling programs for by-products and ensuring proper disposal methods for non-recyclable waste can significantly reduce the environmental footprint.

Water usage is also a concern in the bread crumb production process. Utilizing water-efficient cleaning systems and implementing closed-loop water systems can help conserve water and reduce wastewater discharge. These measures not only benefit the environment but can also result in cost savings for the operation.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com