The Ultimate Guide to Food Machinery in 2024

Introduction

In the fast-paced world of food production, the role of food machinery cannot be overstated. These advanced pieces of equipment serve as the backbone of modern food manufacturing, orchestrating the intricate process of transforming raw ingredients into the diverse array of food products found on supermarket shelves and restaurant menus.

At its core, food machinery represents the culmination of centuries of innovation and technological advancement in the food industry. From the earliest stone mills and hand-operated presses to today's sophisticated automated systems, the evolution of food machinery has revolutionized the way we produce, process, and package food on an industrial scale.

The significance of food machinery lies in its ability to streamline and optimize every step of the food production process. Whether it's mixing ingredients to precise specifications, cooking and baking foods to perfection, or packaging products for distribution, these machines ensure consistency, efficiency, and quality at every stage.

Moreover, food machinery plays a critical role in meeting the ever-increasing demands of consumers and markets worldwide. As populations grow and dietary preferences evolve, food manufacturers rely on these machines to scale up production while maintaining high standards of safety, hygiene, and taste.

In the following sections, we will delve deeper into the diverse types of food machinery, explore the factors that influence their selection and use, and examine the latest advancements shaping the future of food manufacturing. Join us on a journey through the fascinating world of food machinery, where precision engineering meets culinary creativity to bring delicious and nutritious foods to tables around the globe.

Types of Food Machinery

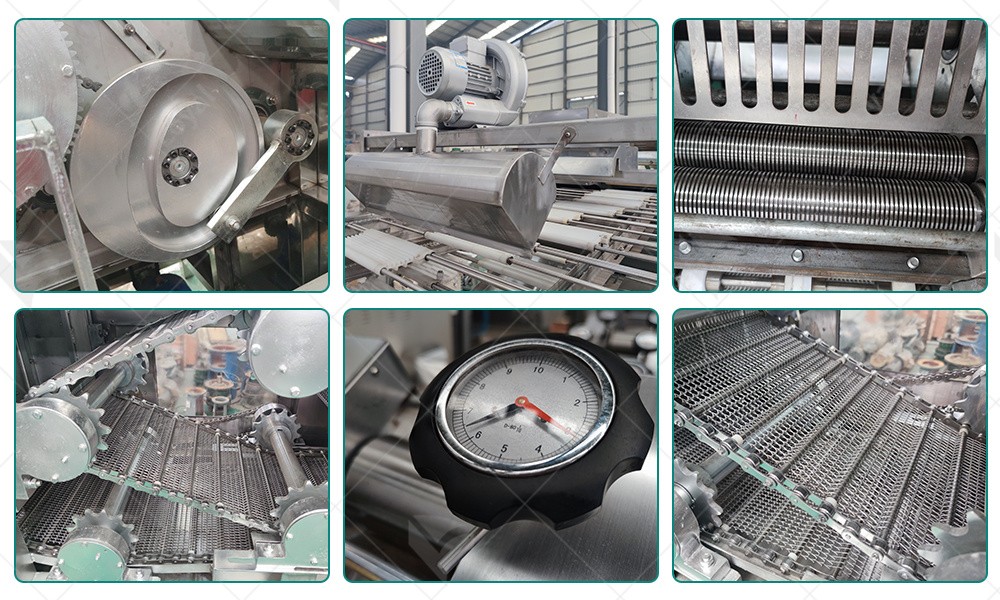

Food machinery encompasses a wide range of specialized equipment designed to perform specific tasks within the food production process. From processing raw ingredients to packaging finished products, each type of food machinery plays a unique role in ensuring the efficiency and quality of food manufacturing. Here are some of the most common types of food machinery:

1. Mixing Equipment: Mixing equipment is essential for blending ingredients uniformly to create dough, batter, sauces, and other mixtures. This category includes dough mixers, blenders, and emulsifiers, which vary in size and capacity depending on the volume and type of ingredients being mixed.

2. Cutting and Slicing Equipment: Cutting and slicing equipment are used to portion and shape ingredients into uniform sizes and shapes. Examples include vegetable cutters, meat slicers, and portioning machines, which improve efficiency and consistency in food preparation.

3. Cooking and Heating Equipment: Cooking and heating equipment are employed to apply heat to food products, ensuring thorough cooking, baking, or roasting. This category includes ovens, grills, fryers, and steamers, each tailored to specific cooking methods and requirements.

4. Cooling and Freezing Equipment: Cooling and freezing equipment rapidly reduce the temperature of cooked or processed foods to prolong shelf life and maintain freshness. Blast chillers, freezers, and refrigeration units are commonly used in food manufacturing facilities to preserve food quality and safety.

5. Packaging Machinery: Packaging machinery encompasses a diverse range of equipment used to package finished food products for distribution and sale. This includes form-fill-seal machines, vacuum sealers, labeling machines, and shrink wrap systems, which automate the packaging process and ensure product integrity.

6. Processing Equipment: Processing equipment is used to transform raw ingredients into semi-finished or finished food products through various methods such as grinding, extrusion, and dehydration. Examples include grinders, extruders, and dehydrators, which enable manufacturers to create a wide range of food products with different textures and flavors.

7. Cleaning and Sanitizing Equipment: Cleaning and sanitizing equipment are essential for maintaining hygiene and food safety standards in food manufacturing facilities. This includes industrial washers, sanitizing tunnels, and chemical dispensing systems, which ensure that equipment and surfaces are thoroughly cleaned and sanitized to prevent contamination.

8. Conveying and Handling Equipment: Conveying and handling equipment facilitate the movement of raw materials, ingredients, and finished products throughout the production facility. This includes conveyors, elevators, and palletizers, which streamline material handling processes and improve operational efficiency.

By utilizing the appropriate types of food machinery for each stage of the production process, food manufacturers can optimize efficiency, consistency, and product quality, ultimately delivering safe and delicious food products to consumers worldwide.

Factors to Consider When Choosing Food Machinery

Selecting the right food machinery is a critical decision for food manufacturers, as it directly impacts production efficiency, product quality, and overall profitability. Several key factors must be carefully considered to ensure that the chosen machinery meets specific production needs and business objectives:

1. Production Capacity: The production capacity of the machinery is a fundamental consideration. Manufacturers must assess their current and projected production volumes to determine the appropriate capacity required. Investing in machinery with the right capacity ensures that production demands can be met efficiently without overstretching resources or underutilizing capacity.

2. Flexibility and Versatility: The machinery's ability to handle a variety of products and adapt to changing production requirements is essential. Versatile machinery that can accommodate different recipes, ingredients, and production processes offers greater flexibility and scalability, allowing manufacturers to respond quickly to market demands and product innovation.

3. Automation and Integration: Automation plays a significant role in enhancing production efficiency and consistency. Machinery equipped with advanced automation features, such as programmable controls, sensors, and robotics, can streamline processes, minimize human error, and increase throughput. Additionally, integration capabilities with other equipment and systems, such as ERP (Enterprise Resource Planning) software, enable seamless data exchange and process optimization across the production line.

4. Quality and Reliability: The quality and reliability of the machinery are paramount to ensure consistent performance and minimize downtime. Choosing reputable manufacturers known for producing high-quality, durable machinery can reduce the risk of breakdowns, maintenance issues, and production disruptions. Additionally, thorough evaluation of the machinery's build quality, materials, and engineering can provide insight into its longevity and performance under heavy usage.

5. Hygiene and Food Safety: Maintaining strict hygiene standards is critical in food manufacturing to prevent contamination and ensure food safety. Machinery designed with hygienic features, such as smooth surfaces, easy-clean components, and sanitation protocols, facilitate thorough cleaning and disinfection, minimizing the risk of microbial growth and cross-contamination.

6. Cost and Return on Investment (ROI): Cost considerations are important when investing in food machinery. Manufacturers must balance their budgetary constraints with the desired features and capabilities of the machinery. Calculating the total cost of ownership, including purchase price, operating costs, maintenance expenses, and expected ROI, helps evaluate the machinery's long-term value and profitability.

7. Regulatory Compliance: Compliance with regulatory standards and industry guidelines is essential to ensure product quality, safety, and legal compliance. Choosing machinery that meets relevant regulatory requirements, such as FDA (Food and Drug Administration) regulations, NSF (National Sanitation Foundation) standards, and CE (Conformité Européenne) certification, helps mitigate risks and avoid costly penalties or recalls.

By carefully considering these factors and conducting thorough research, food manufacturers can make informed decisions when choosing food machinery that aligns with their specific production needs, budgetary constraints, and long-term goals. Ultimately, investing in the right machinery enables manufacturers to enhance efficiency, ensure product quality, and maintain a competitive edge in the market.

Importance of Food Machinery in the Food Industry

In the dynamic and demanding landscape of the food industry, the role of food machinery is indispensable, serving as the cornerstone of modern food manufacturing processes. The significance of food machinery extends far beyond mere automation; it encompasses efficiency, quality assurance, innovation, and sustainability, all of which are essential for the success and growth of food businesses worldwide.

1. Efficiency and Productivity: Food machinery revolutionizes food production by automating repetitive tasks and streamlining complex processes. Whether it's mixing ingredients, cooking, packaging, or cleaning, these machines perform tasks with unparalleled speed and precision, significantly increasing production efficiency and throughput. By minimizing manual labor and reducing cycle times, food machinery enables manufacturers to meet high demand and optimize resource utilization, ultimately driving productivity and profitability.

2. Consistency and Quality Assurance: Maintaining consistent product quality is paramount in the food industry to ensure consumer satisfaction and brand loyalty. Food machinery plays a crucial role in achieving uniformity in taste, texture, and appearance across batches of food products. By precisely controlling factors such as temperature, pressure, and mixing times, these machines ensure that every product meets stringent quality standards, reducing variation and minimizing the risk of defects or recalls.

3. Innovation and Product Development: The continual advancement of food machinery technology fuels innovation and drives product development in the food industry. From advanced mixing and extrusion techniques to novel cooking and packaging methods, these machines enable manufacturers to create new and exciting food products that cater to evolving consumer preferences and market trends. By providing the tools and capabilities to experiment with ingredients, flavors, and textures, food machinery inspires creativity and fosters culinary innovation, driving differentiation and competitive advantage.

4. Food Safety and Hygiene: Ensuring food safety and hygiene is paramount in food manufacturing to prevent contamination and protect consumer health. Food machinery is designed with hygienic features and materials that facilitate thorough cleaning and sanitation, minimizing the risk of microbial growth and cross-contamination. By adhering to strict hygiene protocols and regulatory standards, these machines safeguard the integrity and safety of food products, earning consumer trust and confidence.

5. Sustainability and Resource Efficiency: In an era of increasing environmental awareness and resource scarcity, food machinery plays a vital role in promoting sustainability and resource efficiency. Advanced technologies such as energy-efficient heating and cooling systems, waste reduction measures, and eco-friendly packaging solutions help minimize the environmental impact of food production processes. By optimizing resource usage and minimizing waste generation, food machinery contributes to a more sustainable and resilient food supply chain, aligning with the broader goals of environmental stewardship and corporate responsibility.

In summary, the importance of food machinery in the food industry cannot be overstated. From enhancing efficiency and productivity to ensuring product quality and safety, these machines are indispensable assets for food manufacturers seeking to thrive in an increasingly competitive and complex market. By leveraging the capabilities of food machinery, manufacturers can innovate, differentiate, and deliver high-quality, safe, and sustainable food products that meet the evolving needs and expectations of consumers worldwide.

Latest Technological Advancements in Food Machinery

In recent years, the food machinery industry has witnessed remarkable technological advancements that have revolutionized food manufacturing processes. From precision automation to cutting-edge materials, these innovations have enhanced efficiency, improved product quality, and expanded the capabilities of food machinery.

One significant advancement is the integration of Internet of Things (IoT) technology into food machinery systems. IoT-enabled sensors and devices provide real-time monitoring and data analytics capabilities, allowing manufacturers to optimize performance, predict maintenance needs, and ensure product consistency. This connectivity also enables remote monitoring and control, empowering manufacturers to oversee operations from anywhere, enhancing flexibility and responsiveness.

Another notable development is the rise of robotics in food production. Advanced robotic systems are capable of performing complex tasks such as ingredient handling, assembly, and packaging with unparalleled speed, precision, and reliability. These robots not only increase production efficiency but also improve workplace safety by handling repetitive or hazardous tasks, reducing the risk of injuries and errors.

Furthermore, advancements in materials science have led to the development of food-grade materials that meet stringent safety and hygiene standards. These materials are durable, corrosion-resistant, and easy to clean, making them ideal for use in food machinery components and equipment. Additionally, the use of innovative coatings and surface treatments helps prevent microbial growth and contamination, ensuring food safety and quality.

Overall, these technological advancements represent a paradigm shift in the food machinery industry, enabling manufacturers to achieve new levels of efficiency, productivity, and innovation. By embracing these advancements and integrating them into their operations, food manufacturers can stay ahead of the competition, meet evolving consumer demands, and drive growth and success in the dynamic food industry landscape.

Maintenance and Troubleshooting Tips for Food Machinery

Maintenance and troubleshooting are essential aspects of ensuring the optimal performance and longevity of food machinery. By implementing proactive maintenance strategies and addressing issues promptly, manufacturers can minimize downtime, reduce costs, and maximize operational efficiency.

Regular maintenance involves routine inspections, lubrication, and cleaning of machinery components to prevent wear and tear and identify potential issues before they escalate. Scheduled maintenance tasks, such as replacing worn parts and calibrating equipment, should be carried out according to manufacturer recommendations to maintain peak performance.

In addition to scheduled maintenance, operators should be trained to recognize common issues and perform basic troubleshooting procedures to address minor problems promptly. This includes identifying unusual sounds or vibrations, monitoring temperature and pressure levels, and inspecting equipment for signs of damage or malfunction.

When issues arise, it's crucial to diagnose the root cause promptly and take corrective action to prevent further damage or disruption to production. This may involve adjusting settings, replacing faulty components, or scheduling repairs by qualified technicians.

Furthermore, implementing a robust maintenance management system can help streamline maintenance activities, track equipment performance, and generate maintenance schedules and reports. This allows manufacturers to proactively manage maintenance tasks, prioritize repairs, and optimize resource allocation.

By prioritizing maintenance and troubleshooting efforts, food manufacturers can ensure the reliability, efficiency, and safety of their food machinery, ultimately enhancing overall operational performance and driving business success.

Regulatory Compliance in Food Machinery

Ensuring regulatory compliance is a fundamental aspect of operating in the food manufacturing industry, particularly when it comes to food machinery. Adhering to a myriad of regulations and standards is essential for guaranteeing the safety, quality, and integrity of food products. This section will delve into the key regulatory considerations that food manufacturers must navigate when selecting, installing, and operating food machinery.

1. Food Safety Regulations: Food machinery must comply with strict food safety regulations to prevent contamination and ensure consumer health. These regulations, often enforced by government agencies such as the FDA (Food and Drug Administration) in the United States and the EFSA (European Food Safety Authority) in Europe, set standards for materials, design, construction, and sanitation practices to minimize the risk of foodborne illnesses and ensure the safety of food products.

2. Hygiene Standards: Maintaining high levels of hygiene is crucial in food manufacturing to prevent microbial growth, cross-contamination, and food spoilage. Food machinery should be designed with hygienic features such as smooth surfaces, easy-to-clean components, and sanitation protocols that comply with industry guidelines, such as those outlined by the NSF (National Sanitation Foundation) and EHEDG (European Hygienic Engineering & Design Group).

3. Electrical Safety Standards: Electrical safety standards govern the design, installation, and operation of electrical components and systems in food machinery to prevent electrical hazards and ensure worker safety. Compliance with standards such as UL (Underwriters Laboratories) and CE (Conformité Européenne) certification is essential to mitigate the risk of electrical accidents and fires in food manufacturing facilities.

4. Environmental Regulations: Environmental regulations address the impact of food machinery operations on the environment, including energy consumption, waste generation, and emissions. Manufacturers must comply with environmental regulations such as the EPA (Environmental Protection Agency) regulations in the United States and EU environmental directives to minimize their ecological footprint and promote sustainability in food production.

5. Equipment Safety Standards: Equipment safety standards govern the design, installation, and operation of food machinery to protect workers from hazards such as mechanical injuries, entanglement, and crushing. Compliance with standards such as OSHA (Occupational Safety and Health Administration) regulations in the United States and ISO (International Organization for Standardization) safety standards is essential to ensure a safe working environment and prevent accidents in food manufacturing facilities.

By adhering to these regulatory requirements and standards, food manufacturers can uphold the highest levels of food safety, quality, and compliance, ultimately safeguarding consumer health and confidence in the products they produce. Compliance with regulatory requirements not only mitigates legal and financial risks but also enhances brand reputation and competitiveness in the global food market.

Sustainability and Environmental Considerations in Food Machinery Production Lines

The push for sustainability is reshaping the food machinery landscape, with a focus on eco-friendly operations and minimal environmental impact.

Efficiency and Waste Reduction

Sustainable food machinery is characterized by its efficiency, using less water and energy and generating less waste. This not only conserves resources but also aligns with the economic interests of food producers by reducing operational costs.

Design for the Environment

Modern designs prioritize recyclability and the use of environmentally friendly materials. Machinery is crafted to last, with end-of-life considerations making disassembly and recycling more straightforward.

Regulatory Compliance

Compliance with environmental regulations is a must, with machinery engineered to meet stringent standards for emissions and noise pollution, supporting a cleaner and quieter production process.

In essence, sustainability in food machinery is about creating a production line that is as gentle on the planet as it is effective in output. As the industry moves forward, the emphasis on green practices will only grow, ensuring a sustainable future for food production.

Conclusion

The future of food machinery is poised for innovation and sustainability. As technology advances, we can expect to see machinery that is more efficient, more reliable, and more environmentally friendly.

Innovations on the Horizon

Continued technological advancements promise to make food machinery even more sophisticated. This includes the integration of smart sensors for real-time monitoring, the use of AI for predictive maintenance, and the development of machinery that can adapt to different production needs.

Sustainability as a Core Principle

Sustainability will remain a key focus, with manufacturers aiming to reduce the environmental impact of their machines even further. This could involve the use of more renewable materials, the development of more energy-efficient designs, and the creation of machinery that can be easily recycled at the end of its life.

Regulatory Changes and Compliance

As regulatory landscapes evolve, food machinery will need to adapt to meet new standards. This will require manufacturers to stay informed about changes in regulations and to design machinery that can comply with these requirements.

In summary, the future of food machinery is bright, with a strong emphasis on innovation, efficiency, and sustainability. As the industry continues to grow and change, we can look forward to a new generation of machinery that will help to shape the future of food production.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)