Optimize Pasta Production: Full Automation with High-Efficiency Additives Microwave Sterilization Machine

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Püschner,SAIREM.

The pasta production industry is at the forefront of evolution, necessitating a keen understanding of its current state and demands. This article introduces the theme, "Optimize Pasta Production –Full Automation with High-Efficiency Additives Microwave Sterilization Machine," highlighting the significance of adopting full automation and advanced sterilization methods for optimizing efficiency and quality in pasta manufacturing.

Current Challenges in Pasta Production

Traditional pasta production methods face challenges and limitations that hinder progress. By examining these issues, we can identify the industry's pressing need for innovation and efficiency improvement. This section introduces the pivotal role of advanced technologies, specifically the High-Efficiency Additives Microwave Sterilization Machine, in overcoming these challenges.

Unveiling Additives Microwave Sterilization Technology

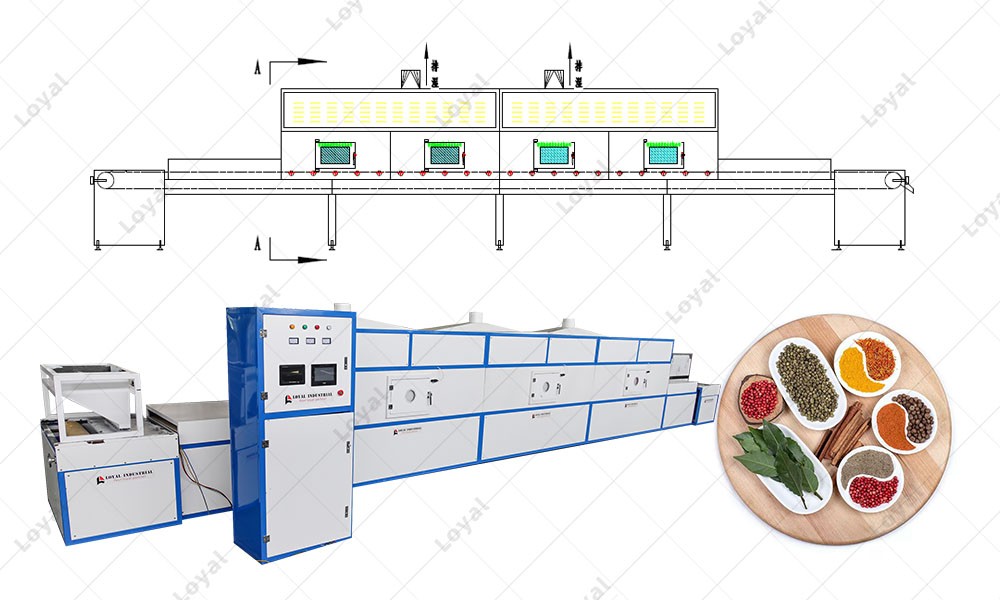

Delving into the principles and mechanisms behind the High-Efficiency Additives Microwave Sterilization Machine, this section unveils its uniqueness and advantages over conventional sterilization methods. The focus is on how this technology aligns with the industry's goals of full automation and elevating product quality in pasta production.

Technological Features of Fully Automated Additives Microwave Sterilization Machine

Providing a comprehensive overview, this section highlights the features defining a fully automated High-Efficiency Additives Microwave Sterilization Machine. Emphasizing precision, speed, and overall efficiency in the sterilization process, it illustrates how automation contributes to optimizing pasta production.

Real-world Impact and Success Stories

By showcasing practical applications of fully automated High-Efficiency Additives Microwave Sterilization Machine in pasta production, this section presents testimonials and success stories from businesses that have embraced this technology. Quantifiable improvements in efficiency, quality, and overall pasta processing due to full automation are emphasized.

Advantages for the Pasta Industry

This section examines the tangible benefits experienced by pasta producers through fully automated High-Efficiency Additives Microwave Sterilization. Preservation of flavor, texture, and nutritional value in pasta products, coupled with increased production capacity, reduced processing time, and enhanced overall quality, signifies a transformative era in optimized pasta production.

Overcoming Challenges in Implementation

Identifying challenges associated with implementing fully automated High-Efficiency Additives Microwave Sterilization Machine, this section provides effective solutions to overcome potential obstacles. Strategies for a seamless integration process in pasta production facilities are outlined, ensuring a smooth transition to advanced technologies.

Regulatory Compliance and Safety Standards

Discussing the importance of meeting regulatory requirements in the pasta industry, this section examines how fully automated High-Efficiency Additives Microwave Sterilization ensures compliance with safety standards. Collaboration with regulatory authorities is explored to establish industry best practices.

Future Trends and Innovations

As we peer into the future of pasta production, several trends and innovations are expected to shape the continued application of fully automated High-Efficiency Additives Microwave Sterilization. Here's what lies on the horizon:

Anticipate a surge in sustainability measures within pasta production. The industry will likely witness innovations that align with environmental consciousness, such as energy-efficient sterilization processes and eco-friendly packaging solutions.

The integration of AI into the pasta production process is poised to enhance efficiency further. AI algorithms could optimize sterilization parameters, ensuring precise and adaptive control over the High-Efficiency Additives Microwave Sterilization Machine.

Future trends suggest a move towards customization and personalization in pasta products. The technology may evolve to accommodate varied consumer preferences, allowing for tailored adjustments in sterilization processes to achieve specific product characteristics.

The industry is likely to witness increased global collaboration to establish standardized practices for fully automated High-Efficiency Additives Microwave Sterilization. This collaboration aims to create a cohesive approach to regulations, ensuring uniformity in safety and quality standards across regions.

In embracing these future trends and innovations, the pasta industry is poised for a dynamic transformation. The convergence of technological advancements, sustainability initiatives, and global collaboration will define the next chapter in pasta production, ensuring a future where quality, efficiency, and innovation harmoniously coexist.

Common Questions About Additives Microwave Sterilization Machine

How does the Additives Microwave Sterilization Machine differ from traditional sterilization methods?

The Additives Microwave Sterilization Machine utilizes microwave technology, offering a faster and more efficient sterilization process compared to traditional methods. Its ability to penetrate materials evenly sets it apart, ensuring a thorough sterilization.

What advantages does full automation bring to pasta production with this technology?

Full automation with the High-Efficiency Additives Microwave Sterilization Machine brings precision and speed to the sterilization process. This results in increased production capacity, reduced processing time, and improved overall quality in pasta products.

Can the flavor, texture, and nutritional value of pasta products be preserved through this sterilization method?

Absolutely. The High-Efficiency Additives Microwave Sterilization Machine excels at preserving the flavor, texture, and nutritional value of pasta products. This is crucial for meeting consumer expectations for high-quality pasta.

What challenges might businesses face during the implementation of fully automated Additives Microwave Sterilization?

Challenges in implementation could include initial setup costs, staff training, and adapting existing production processes. However, the article addresses effective solutions to these challenges, ensuring a smooth integration into pasta production facilities.

How does the technology ensure regulatory compliance and adhere to safety standards in the pasta industry?

The article discusses the importance of meeting regulatory requirements in the pasta industry and details how the fully automated High-Efficiency Additives Microwave Sterilization Machine ensures compliance with safety standards. Collaboration with regulatory authorities is emphasized for establishing best practices.

What future trends and innovations can we expect in the application of this technology?

The exploration of anticipated trends and innovations in the continued application of fully automated High-Efficiency Additives Microwave Sterilization provides insights into the evolving landscape. The article discusses upcoming advancements that could further enhance efficiency and sustainability in pasta processing.

Conclusion

In conclusion, the article has taken a comprehensive journey through the optimization of pasta production via full automation with the High-Efficiency Additives Microwave Sterilization Machine. From addressing current challenges to unveiling the technological intricacies and showcasing real-world impacts, the article underscores the transformative potential of this innovative approach. As businesses look to the future, embracing such cutting-edge technologies becomes not just a necessity but a strategic imperative. The pasta industry stands at the threshold of a new era, where efficiency, quality, and safety converge to define the next generation of pasta processing.