Advancing Quality and Efficiency: High-Efficiency, Fully Automatic Microwave Sterilization in the Condiment Industry

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Ferrite,DanTech UK Ltd.

The condiment industry is undergoing a paradigm shift as it seeks to enhance both quality and efficiency in its production processes. This introduction sets the stage for our exploration into the transformative impact of high-efficiency, fully automatic microwave sterilization on condiment manufacturing. The adoption of innovative sterilization methods becomes crucial in meeting the ever-evolving standards of the industry.

Current Landscape of Sterilization in the Condiment Industry

This in-depth analysis unveils the challenges and limitations posed by traditional sterilization methods within the condiment industry. The existing landscape reveals that conventional techniques, while prevalent, often fall short in meeting the evolving standards of quality and safety in condiment production. The inefficiencies and drawbacks inherent in these methods emphasize the critical need for a transformative shift towards high-efficiency solutions.

Traditional sterilization techniques, including heat pasteurization and chemical methods, have been the backbone of condiment processing for years. However, their limitations in preserving the sensory attributes, nutritional content, and overall quality of condiments have become increasingly evident. Consumers today demand products that not only meet safety standards but also retain the authentic flavors and textures they expect.

This sets the stage for a compelling discussion on the urgent requirement for high-efficiency solutions within the condiment industry. As we delve into the challenges associated with traditional techniques, the spotlight is on the industry's quest for advancements that go beyond mere compliance with safety regulations. The pressing need is to embrace technologies that not only ensure safety but also enhance the overall quality of condiment products.

The limitations of existing sterilization methods become the catalyst for exploring innovative approaches, particularly focusing on high-efficiency solutions. The quest for these solutions becomes a pivotal driver in propelling the condiment industry towards a future where quality and safety standards are not just met but exceeded. This groundwork sets the context for our detailed examination of the revolutionary microwave sterilization technology and its potential to address these pressing industry needs.

The Emergence of Microwave Sterilization

In our exploration of the emergence of microwave sterilization, we unravel the intricacies of this cutting-edge technology, delving into its principles and mechanisms. Microwave sterilization represents a transformative shift in the field of food processing, particularly in the condiment industry. This section aims to provide a comprehensive understanding of how microwave sterilization stands out with its unique characteristics and outperforms traditional methods.

Microwave sterilization operates on the fundamental principle of utilizing electromagnetic waves to heat the condiment products. Unlike conventional methods that rely on external heat sources, microwave sterilization penetrates the product directly, resulting in a more rapid and uniform heating process. This not only ensures the elimination of harmful microorganisms but also minimizes the impact on the sensory attributes of condiments.

The mechanisms behind microwave sterilization involve the interaction between electromagnetic waves and water molecules within the condiment products. As these waves penetrate the material, water molecules absorb the energy, leading to a rise in temperature. This controlled and precise heating is a key feature that distinguishes microwave sterilization from traditional methods, where external heat may cause uneven processing.

The advantages of microwave sterilization become apparent as we explore its ability to maintain the nutritional value, flavor, and texture of condiment products. Unlike heat pasteurization, which can result in overcooking and loss of sensory attributes, microwave sterilization offers a more gentle yet highly effective approach. This aligns with the evolving consumer preferences for minimally processed and nutritionally rich food products.

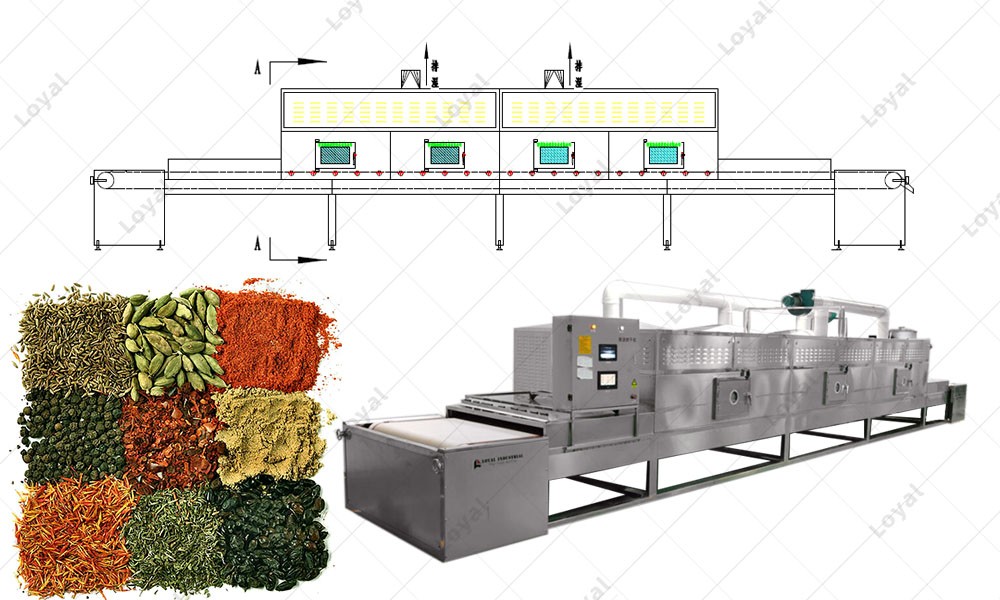

High-Efficiency, Fully Automatic Microwave Sterilization Technology

This section serves as a crucial foundation for the subsequent examination of high-efficiency, fully automatic microwave sterilization technology. By understanding the principles and advantages of microwave sterilization, we set the stage for a detailed exploration of how these advancements can revolutionize the condiment industry's approach to sterilization, ensuring both quality and efficiency in the processing of condiment products.

This section delves into the technological marvel that is high-efficiency, fully automatic microwave sterilization, providing a comprehensive overview of its defining features. We emphasize precision, speed, and efficiency as key elements that set this technology apart, showcasing how it effectively addresses specific challenges encountered by the condiment industry and propels a qualitative leap in the sterilization process.

Speed and Time-Saving Advantages

One of the defining features of this technology is its remarkable speed in achieving sterilization. The fully automatic nature of the process, coupled with the rapid heating capabilities of microwave sterilization, significantly reduces the overall processing time. This swift turnaround translates into increased production capacity, allowing condiment manufacturers to meet market demands efficiently.

Efficiency is at the core of high-efficiency, fully automatic microwave sterilization. The technology optimizes the sterilization process, minimizing energy consumption while maximizing throughput. Automated controls and precision monitoring contribute to a streamlined production flow, reducing manual interventions and ensuring a consistent and efficient sterilization outcome across batches.

This section highlights how high-efficiency, fully automatic microwave sterilization specifically tackles challenges faced by the condiment industry. Issues such as uneven heating, overcooking, and extended processing times, which are common in traditional methods, are effectively addressed. The result is a more controlled and efficient sterilization process that aligns with the industry's quest for enhanced quality and safety.

By examining these technological features in detail, we gain insight into how high-efficiency, fully automatic microwave sterilization technology becomes a game-changer for the condiment industry. The precision, speed, and efficiency it brings to the sterilization process contribute to advancing the quality and efficiency of condiment processing, marking a significant step forward in the industry's pursuit of innovation and excellence.

Case Studies: Transformative Applications

A prominent condiment manufacturer faced challenges in maintaining consistent quality and efficiency in their production processes.

The adoption of high-efficiency, fully automatic microwave sterilization technology revolutionized their production line. The precision and speed of the process led to a significant reduction in processing time, enabling the manufacturer to meet growing market demands seamlessly.

The technology preserved the natural flavors and textures of condiments, ensuring a superior end product.Automated controls streamlined the production flow, reducing manual interventions and minimizing errors.With faster processing times, the manufacturer experienced a notable increase in overall production capacity.

Overcoming Challenges in Implementation

Identifying and addressing challenges associated with implementing high-efficiency, fully automatic microwave sterilization is crucial for seamless integration. This part explores strategic solutions and best practices to ensure a smooth transition for condiment production facilities.

Highlighting the importance of meeting regulatory requirements, this section examines how high-efficiency, fully automatic microwave sterilization ensures compliance with safety standards. Collaboration with regulatory authorities becomes integral in establishing industry best practices for the condiment sector.

Future Trends and Innovations

Anticipating future trends in high-efficiency, fully automatic microwave sterilization, we explore potential innovations that could further enhance efficiency and sustainability in condiment processing. The role of technology in shaping the industry's future is central to this forward-looking discussion.

Conclusion

Summarizing the transformative impact of high-efficiency, fully automatic microwave sterilization on the condiment industry, this conclusion encourages businesses to adopt innovative technologies. The call is for enhanced quality, efficiency, and safety, providing a forward-looking perspective on the ongoing evolution of sterilization practices in the condiment industry.