Modified Starch Manufacturing Process

After pregelatinized starch manufacturers use modified starch machine being processed by a certain method, the nature starch changes its original physical or chemical properties to varying degrees. In order to improve the performance of starch and expand its application range, physical, chemical or enzymatic treatment is used to introduce new functional groups on starch molecules or change the size of starch molecules and the properties of starch granules, thereby changing the natural characteristics of starch (eg gelatinization temperature , Thermal viscosity and its stability, freeze-thaw stability, gel strength, film formation, transparency, etc.), making it more suitable for certain application requirements. This kind of starch that has undergone secondary modified starch manufacturing process to change its properties is collectively called modified starch.

The first purpose of denaturation is to adapt to the requirements of various industrial applications. Such as: high temperature technology (canned sterilization) requires starch high temperature viscosity stability, frozen food requires starch freeze-thaw stability, jelly food requires good transparency, good film formation and so on. The second is to open up new uses of starch and expand the scope of application. For example: Modified starch is used in textiles; hydroxyethyl starch and hydroxypropyl starch are used to replace plasma; high cross-linked starch is used to replace talc for surgical gloves.

The first purpose of denaturation is to adapt to the requirements of various industrial applications. Such as: high temperature technology (canned sterilization) requires starch high temperature viscosity stability, frozen food requires starch freeze-thaw stability, jelly food requires good transparency, good film formation and so on. The second is to open up new uses of starch and expand the scope of application. For example: Modified starch is used in textiles; hydroxyethyl starch and hydroxypropyl starch are used to replace plasma; high cross-linked starch is used to replace talc for surgical gloves.

Modified starch manufacturing process produced by modified starch manufacturer has been professionally designed to adjust the structure of the machine cavity and the screw to diversify the functions of the modified starch. The pregelatinized starch manufacturing process make modified starch series products are suitable for textile, food, paper, building materials, casting, oil drilling and other fields With the deepening of research, the extruder will play an increasingly important role in the modified starch market. The machine consists of feeding system, extrusion system, rotary cutting system, heating system, transmission system and cooling system.

Modified starch can be widely used in putty powder, chemical product adhesives, food processing, brewing and other industries

Modified Starch Process flow:

Modified Starch Process flow:

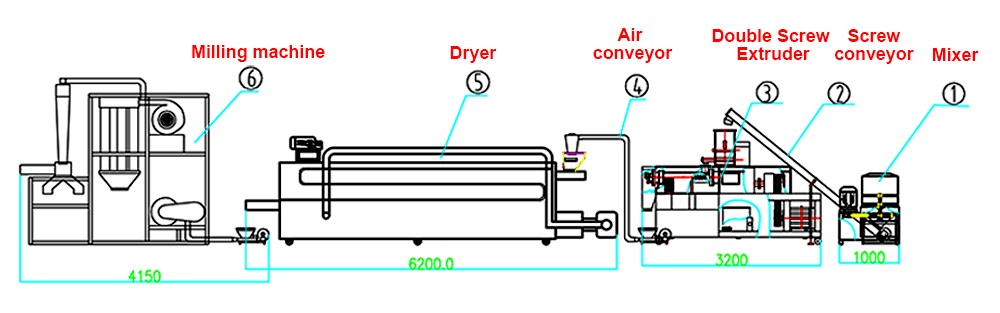

raw material preparation→mixing→transportation→extrusion→transportation→drying→crushing→packaging

pre-gelatinized starch machine configuration:

mixer → Screw Conveyor → twin screw extruder → air conveyor → Industrical Dryer → grinder → packaging machine

|

Pre Gel Starch modification process |

|

Mixer |

|

♥ Main structure: the flour mixer machine consists of a frame, transmission parts, mixer and cylinder parts. ♥Using method: Put flour into the machine tube, turn on the motor, add other material, after mixing till your requirement, open the door, the powder will be push out by mixing wing. ♥Mix starch (corn starch, tapioca starch, potato starch, etc.) alone or with some additives, add a certain amount of water and mix well.. |

|

Screw Conveyor |

|

♥ the motor is used for power screw conveying, and the mixed raw materials are sent to the feeding hopper of the extruder to ensure that the feeding is convenient and fast. |

|

Twin Screw Extruder |

|

♥ There is a special control cabinet to extrude modified starch granules under high-temperature and high-pressure environment. Adjusting the process and changing the mold can produce different products.; |

|

Air Conveyor |

|

♥The particles are transported to the oven, and the height of the elevator is determined according to the oven.. |

|

Industrial Dryer |

|

♥ This kind of oven has a wide range of application. It can dry all shapes of puffing food, including strip, lump, granular materials etc, as well as other types of materials. Users can choose different types with different layer, length, and heating mode. ♥ It has compact design and easy operation. ♥ The oven is droved with double pitch roller chain and heats materials circularly. It runs smoothly, never obstruction.

|

|

grinding machine |

|

Function:- Choose different crushers to crush according to the requirements of modified starch. ♥ This grinding machine is applied in such trades as pharmaceutical, chemical, foodstuff, magnetic material, powder etc. It is a new generation crushing equipment combining crushing, dust-collecting and continuous-discharge into a unit.

♥ The machine is composed of crusher, cyclone separating device, pulse dust absorption box and blower, etc. The machine is working by relative movement of valiant disc and fixed fluted disc, making the material be crushed. The crushed material is fed into cyclone separating device by rotating centrifugal effect and gravitation of blower and get out via discharger. The dust is fed into dust absorption box and recycled via filter, the fineness can be regulated by changing the sieve. |

|

Packing machine |

|

Packing the differemt modified to the bag for sale |

A cross-section of a gelatinatized starch screw extruder: 1 - engine, 2 - feeder, 3 - cooling jacket, 4 - thermocouple, 5 – screw, 6 - barrel, 7 - heating jacket, 8 - head, 9 - net, 10 -cutter, I - transport section, II – compression section, III –melting and plasticization section

The technological assessment of gelatinatized starch extrudates takes two factors into account: the water solubility index (WSI) and the water absorption index (WAI). WAI of many starch products increases together with the temperature rising in the extruder’s barrel. It has been assumed that the maximum value is obtained around the temperature ranges from 180 to 200 °C. When these temperatures are exceeded, WAI drops and causes the WSI increase. The lower material initial moisture content used in extrusion, the higher extrudate’s WSI rate can be obtained. A noticeable influence on the product properties has the percentage of amylose and amylopectin and its ratio in the processed material.

The technological assessment of gelatinatized starch extrudates takes two factors into account: the water solubility index (WSI) and the water absorption index (WAI). WAI of many starch products increases together with the temperature rising in the extruder’s barrel. It has been assumed that the maximum value is obtained around the temperature ranges from 180 to 200 °C. When these temperatures are exceeded, WAI drops and causes the WSI increase. The lower material initial moisture content used in extrusion, the higher extrudate’s WSI rate can be obtained. A noticeable influence on the product properties has the percentage of amylose and amylopectin and its ratio in the processed material.

The modified starch extrusion processing of starchy materials certainly impacts the changes in product viscosity (pasting characteristic) after dissolving in water. This feature is very important for the technological point of view. Using Brabender viscometer we can see that the characteristic viscosity curve for starch is clearly reduced through extrusion; at the same time, the decrease of viscosity is greater if higher temperatures were applied during the extrusion-cooking. The application of higher pressure during the extrusion (compression changing) does not affect the extrudate viscosity; however, it affects on viscosity stability of products retained at a temperature of 95 °C. In some cases, the properties of extrudate may be arranged by amylose bounding with fatty acids or monoglycerides.

Another factor determining changes in the starch molecules during the extrusion-cooking process is the pressure and the values of existing shearing forces. In order to obtain certain technological properties of extrudates, which are often semi-finished products intended for further processing, it is necessary to set proper parameters of the extrusion process. This is achieved by the use of screws with varying compression degrees, relevant rpm of the working screw, appropriate die size, SME input, etc.