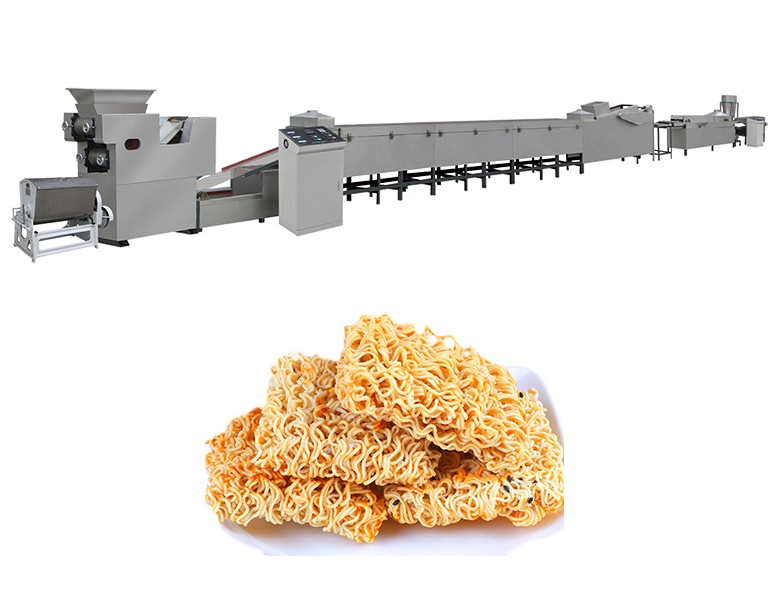

How are noodles made in factory?

The acceleration of the social rhythm has greatly compressed our time. Which has led to many people often not having time to eat. And casually grabbing a few mouthfuls between work. Diet is very important to us and is the basis for our health. Under this demand, instant noodles have become the best choice for the public.

Instant noodles are also called instant noodles and instant noodles. You can get delicious food in a few minutes by brewing with hot water. Which brings great convenience to our lives and the demand is also very high. So how do food manufacturers produce such delicious and convenient food?

How are noodles made in factory?

The professional technical article in the top ten instant noodle production lines by sales in 2021 shows that due to the huge demand now. It is very profitable to engage in the instant noodle industry. And manufacturers can make huge profits from this industry. The manufacture of instant noodles is not difficult. You only need to use the Instant Noodles Production Line to mix flour, salt, edible oil, whole egg powder and other raw materials. Through the steps of mixing, pressing, noodles, frying, cooling, and packaging. Delicious instant noodles.

Next, we will learn in detail how the production line produces instant noodles:

Dough machine

The main function of the flour mixer is to mix flour, salt, alkali, water and other additives uniformly. This is the first step in instant noodle production. In this process, various raw materials need to be weighed in strict accordance with the formula to ensure the taste of the noodles.

Forming Machine

The uniformly mixed dough is conveyed to the forming machine. The roller belt can squeeze the dough into a smooth strip with a thickness of about 1mm. Then it is cut into strips with a cutting knife. The wave shaper allows each noodle to be used. Becoming wavy, the wavy noodles can increase the contact area with the air, thereby reducing the soaking time during frying and eating.

Boiling machine

The cut noodles will be transported to the boiling machine for steaming. After steaming for about 1-5 minutes, the steamed noodles will be tougher and more transparent.

Cutting Machine

The cutting machine will cut the noodles into different lengths. Different types of instant noodles may have different weights. At this time, you only need to change the cutting length.

Fryer

The cut noodles will be conveyed to the fryer for frying. High-temperature frying can make the noodles dehydrated and shaped in the shortest time. After frying, the taste of instant noodles will be richer and the shelf life will be longer.

Cooler

The main function of the cooler is to quickly cool the noodles. If the instant noodles fried at high temperature are packaged directly without cooling, it will easily regain moisture and become soft in the packaging bag, the taste will become worse, and the shelf life will be shortened.

Packing Machine

The packaging machine can realize fast and efficient packaging. The seasoning bag can be automatically placed on each piece of noodles during packaging, and then the packaging machine can automatically make bags to pack the noodles and the seasoning bag at the same time.

In this way, the instant noodles are produced, and then they will be shipped to major stores to be purchased by consumers. In the production process of instant noodles, the production line has played a very important role, and a highly automated production method is the key to ensuring production quality and production efficiency.

As a professional food machinery manufacturer, our company shoulders the mission of reform and innovation in the food processing industry. The various food machinery produced over the years have been well applied in the actual production of the manufacturer, which has brought development to many enterprises. opportunity. Our Instant Noodles Production Line has reached the world's leading level, and it is an equipment recognized by many well-known manufacturers.

This production line is a fully automatic production line with perfect technology, compact structure, novel design, stable performance and low price developed by our engineers on the basis of learning from similar products and requirements in the international market. It has realized a highly automated production method, has the advantages of convenient operation, low energy consumption, and small footprint. It can complete all production procedures at one time. At the same time, the low price is the gospel of many small and medium-sized enterprises.

If you want to show your skills in the instant noodle industry, welcome to contact us, I believe our cooperation will surely give you unexpected surprises!