How About Puffed Cereal Corn Flakes Equipment?

How about puffed cereal corn flakes equipment?

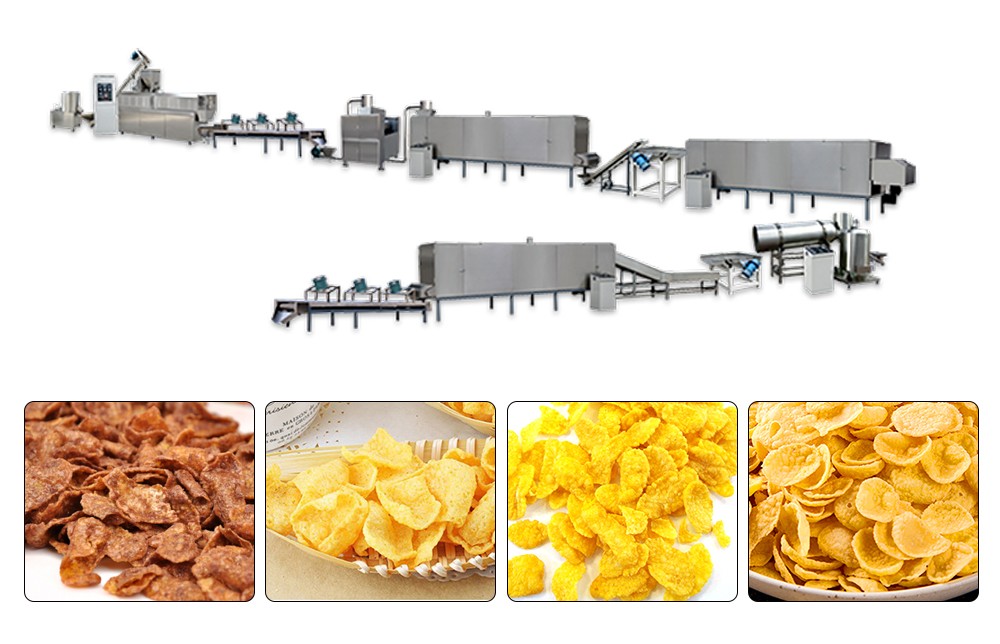

Breakfast cereal corn flakes, cereal flakes, and baked ready-to-eat oatmeal are a kind of crisp food, which can be eaten directly or brewed with yogurt or milk. It has good rehydration, does not rotten on the outside, has a smooth taste, and has a strong grain flavor. . Puffed cereal corn flakes are mainly made of corn flour as the main raw material, after being puffed by a puffing machine, then compressed by a tablet machine, and then baked and matured by a second time. The cereal is softened by steaming and softening of the cereal, and then after being matured by the tablet machine. The two types of equipment can be shared. The cereal and corn flakes produced by puffed cereal corn flakes equipment can be mixed with sugar, various vitamins and minerals, and can also be mixed with dried fruit, yogurt, coconut flakes, etc. Cereal corn flakes equipment produces popular instant cereal products or breakfast cereal crisp meal replacement foods on the market.

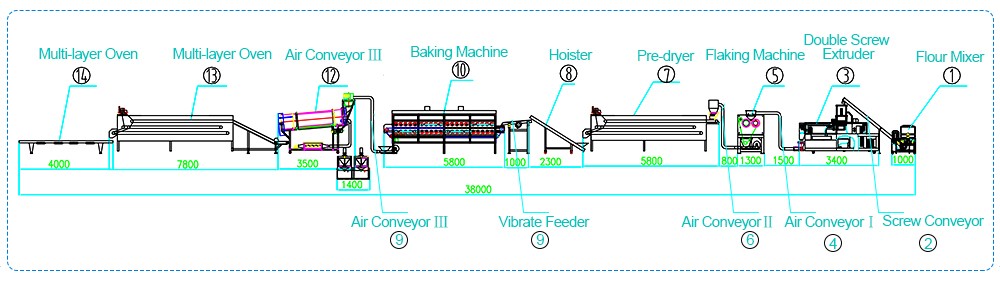

1. Corn flake equipment Process flow of corn extruder: raw material preparation → powder mixing → conveying → extrusion and puffing → conveying → tableting → conveying → drying → (packing)

2. Corn flakes equipment Corn extruder equipment configuration: flour mixer → feeder → puffing machine → air conveyor → tablet press → air conveyor → multi-layer oven → (packing machine)

Wide range of raw materials: rice, corn, oats, buckwheat, soybean meal and starch. Variety of products: snack food, crispy rice, sandwich food, instant rice porridge, nutritious rice noodles, bread crumbs. Longer service life: The screw and barrel are made of high-quality alloy steel, which is processed by quenching and tempering, forming nitriding, fine grinding and polishing, so that it has high strength, wear resistance, high pressure, and guarantees long life operation of the screw.

The material of puffed corn flakes is fed by the feeder. In addition, the barrel is subjected to high temperature, high pressure and high shear, so that the material expands to meet the quality requirements, similar to the required organization state. Highlights of puffed cereal corn flakes equipment: 1. Adopt advanced frequency converter speed regulation technology to make the equipment run more smoothly and save power; 2. Screws are made of alloy steel nitriding, which has a longer service life. It adopts a combined structure of building blocks, 3. Forced lubrication system to ensure a longer life for the transmission part of the equipment; 4. Visualized automatic temperature control system, which makes temperature control more intuitive and more parameters;

Other advantages of puffed cereal corn flakes equipment

1. Provide general formulas for each category;

2. A variety of shapes can be selected;

3. Free pre-sale consulting services, equipment services in sales, service installation and commissioning and training services;

4. Responsible for training personnel and guidance services;

5. Provide customers with R&D production line layout and layout services, and provide detailed plans in accordance with the purchase of customers' factories or actual conditions.

6. According to the workshop scale that the purchaser can provide.

The requirements for the tablet press are relatively high, the surface of the roller must have a high surface finish, and the roller must be kept at a constant temperature.

High temperature baking: Whether the corn flakes have a hard, crisp, dense structure and outstanding corn flavor, the baking process is extremely important. After the roasted corn flakes cool, it becomes a corn flake product. At present, many puffed cereal corn flakes are processed through post-processing, such as sugar, fried salt or chocolate, which mainly depends on market demand. The production requirements of puffed cereal corn flakes are high, and the process conditions are harsh. Stable and stable R&D and production equipment are required to ensure the process conditions of each R&D and production link in large-scale industrial production.

In order to meet the domestic breakfast cereal R&D and design needs and truly get rid of the high investment in imported equipment, our company has developed the equipment required for the breakfast cereal R&D and design, such as twin-screw extruders, dryers, tablet presses, and ovens. Wait.

I believe that in the near future, we will choose this equipment to create benefits.