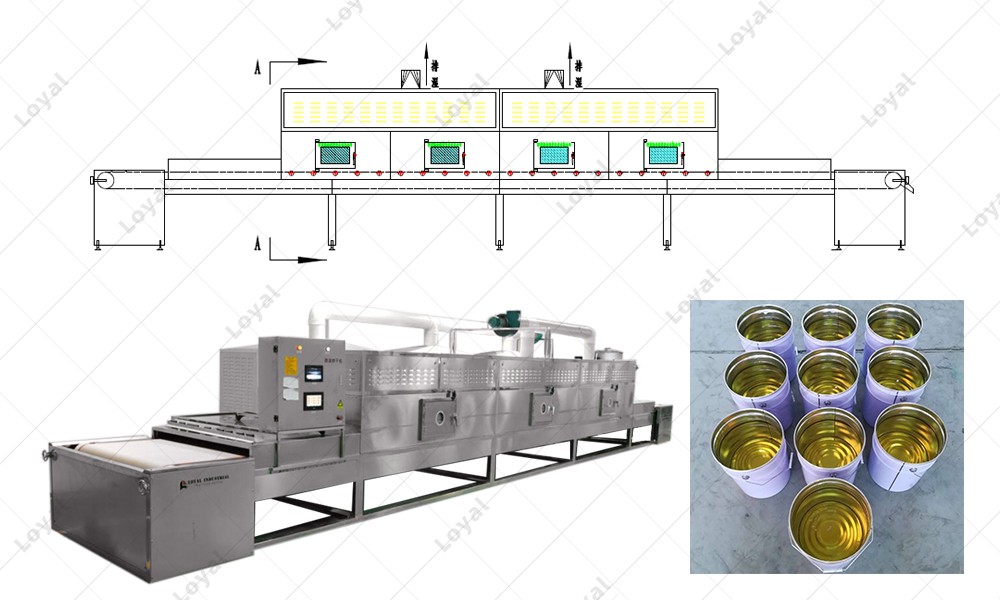

Epoxy Resins Drying Microwave Oven

Description Of Epoxy Resins Drying Oven

Epoxy resin drying oven is an oven specially designed for curing and drying epoxy resin coatings, adhesives and other products. These ovens contain a heating system that heats the air to a specific temperature and circulates it evenly throughout the oven to ensure a consistent temperature. Ovens typically range in temperature from 50°C to 200°C and may have multiple chambers to cure or dry different products simultaneously. The oven's temperature control system is carefully calibrated to ensure that the oven maintains a constant temperature, which is critical to the epoxy curing and drying process. Epoxy drying ovens are available in stainless steel inside and out for durability and easy cleaning. It may also have a built-in air filtration system to remove any particles or contaminants that may affect the quality of the epoxy coating or adhesive. Overall, an epoxy drying oven is an essential tool in the manufacture of epoxy resin products and is essential to ensure the correct properties and high quality of the product.

How To Dry The Epoxy Resins

1.Prepare the epoxy resin product according to the manufacturer's instructions.

2.Load the product into the oven. Make sure it is placed correctly and not crowded, as this may affect the quality of curing and drying.

3.Set temperature and time settings according to manufacturer's recommendations. These guidelines must be followed to ensure that the epoxy cures and dries properly.

4.Turn on the oven and let it reach the desired temperature. Wait for the oven to stabilize at the set temperature.

5.Monitor curing and drying progress through the oven window (if present). If not, you can occasionally turn on the oven to check the progress.

6.After the curing and drying process is complete, turn off the oven and allow to cool before removing the product.

7.Remove product from oven and allow to cool to room temperature before handling or packaging.

Note: Always follow safety procedures when using the oven, including wearing heat-resistant gloves, proper ventilation, and avoiding contact with hot surfaces.

Working Principle Of Industrial Microwave Epoxy Resins Drying Oven

The working principle of the industrial microwave epoxy resin drying oven is to use microwave radiation to generate heat in the oven, and the heat interacts with the epoxy resin to cure and dry it. The oven contains a magnetron that generates microwaves that are directed into the drying chamber through waveguides. Epoxy products are placed in a drying chamber where microwaves rapidly heat the resin and hardener molecules. This causes the resin to polymerize and harden, resulting in a durable high-performance material. The microwave drying process is generally faster than traditional oven drying methods because it directly heats the resin without preheating or lengthy curing times. Additionally, the use of microwaves reduces the risk of overheating or undercuring the epoxy, resulting in a more consistent and reliable product. Overall, industrial microwave epoxy drying ovens provide a cost-effective method of curing and drying epoxy resins for a variety of industrial applications.

Microwave Epoxy Resins Dryer's Advantage

|

Faster Drying Time |

Microwave drying is generally faster than conventional oven drying because microwaves directly heat the resin and hardener molecules. |

|

Energy Efficiency |

Microwave drying uses less energy than other drying methods, saving money and reducing environmental impact. |

|

Improved Product Quality |

The use of microwave drying reduces the risk of under-curing or over-curing epoxy resin products, resulting in a more consistent and high-quality end product. |

|

Productivity |

Microwave drying eliminates the need for lengthy preheating or curing times, resulting in faster production and greater efficiency. |

|

Safety |

The use of microwave drying reduces the risk of fire or explosion because it does not require an open flame or high heat source. |

Overall, industrial microwave epoxy drying ovens are an efficient, economical and safe way to cure and dry epoxy resins for a variety of industrial applications.

Epoxy Resins Product Display

Epoxy resin is a thermosetting synthetic polymer widely used in the manufacture of various products. They are known for their exceptional strength, durability and resistance to abrasion, chemicals and moisture. Epoxy resins are used as adhesives, sealants or coatings for a wide variety of materials, including metals, ceramics, composites, plastics and glass.

Some common products made with epoxy resins include:

|

Flooring Systems |

Epoxy flooring is a popular choice for industrial and commercial facilities due to its strength and durability. It is commonly used in factories, warehouses, hospitals, and even residential garages. |

|

Adhesives |

Epoxy adhesives are used in a variety of applications including automotive, construction, aerospace and electronics. They have excellent adhesive properties and can be used to bond many different materials. |

|

Composite Materials |

Epoxy resins are often used as a matrix material for composite products such as glass fibers or carbon fibers. These composites are used in many applications including aerospace, marine, automotive and sporting goods. |

|

Electrical And Electronic Components |

Epoxies are often used to encapsulate electronic components, protecting them from moisture and other environmental elements. They are also used in printed circuit boards and other electronic devices. |

|

Protective Coatings |

Epoxy coatings are used to protect a variety of surfaces including metal, concrete and wood. They offer excellent abrasion, chemical and moisture resistance, making them ideal for use in harsh environments. |