Brief introduction of pet food production line

Now there are more and more pet owners. Kittens and puppies can bring us a lot of spiritual comfort, especially some young people who are drifting away. The companionship of pets can bring a lot of warmth, so the pet market is now developing rapidly.

Correspondingly, the demand for pet food has also risen sharply. As the current consumer's economic level has been greatly improved, and the purchasing power has further increased, there are also higher quality requirements for pet food. In order to be recognized by more consumers, we purchased and used a new type of food machinery-Pet Food Production Line. After using it, we found that this equipment has many advantages.

The advantages of the pet food production line are very significant:

1. The entire production line is made of food-grade stainless steel, with reliable quality and long service life.

2. With a fully automated production method, the production efficiency is very high, and the market can be further developed with high quality and efficiency.

3. The PLC control system is adopted, which is easy to operate and easy to maintain, and can be easily operated by ordinary workers.

4. The pet food produced has high nutrient content and good palatability.

5. It can process and produce a variety of pet foods with a wide range of uses.

After using the pet food production line, our production efficiency has been greatly improved, the food quality has also been guaranteed, and our competitiveness in the market has been effectively improved.

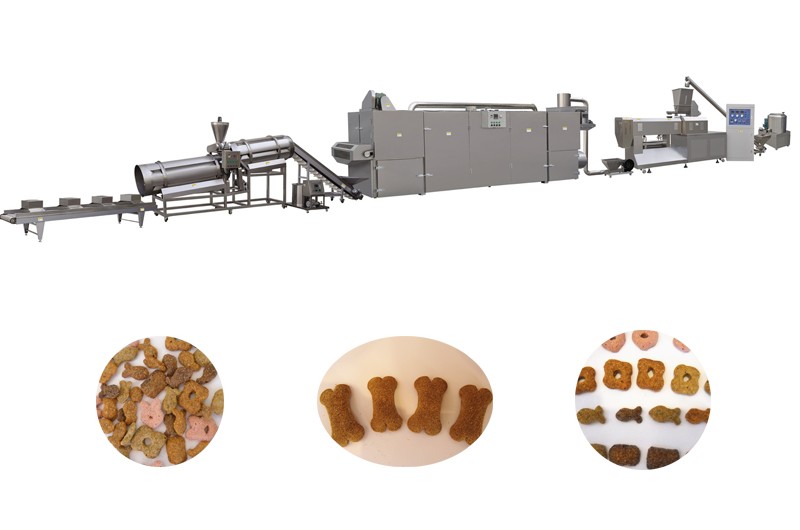

The pet food production line is composed of a mixer, a screw conveyor, an extruder, a dryer, a spraying machine, a cooler, and a packaging machine. It undergoes raw material mixing, extrusion, drying, seasoning, cooling, and packaging. Produce pet food.

The main purpose of each equipment of the pet food production line:

1. Mixer: Mix grain meal, bone meal, soybean meal, some vitamins and minerals and other raw materials evenly.

2. Screw conveyor: adopts the form of multi-angle conveying to convey the raw materials to the extruder. The conveying process is clean and sanitary, pollution-free, and has high sanitary standards.

3. Extruder: A high-temperature and high-pressure environment will be formed in the extruder. In this state, the raw materials are extruded and expanded to form, which can retain most of the nutrients in the raw materials, and only need to change the mold to produce a variety of Pet food in different shapes, including round, triangular, and bone shapes.

4. Dryer: Dry pet food to effectively extend the shelf life of pet food.

5. Spraying machine: spray some grease on pet food to make pet food more rich in taste and palatability.

6. Cooler: Quickly cool pet food to prevent moisture recurrence after packaging and reduce the quality of food.

7. Packaging machine: Fully automated packaging of pet food.

Using the above equipment, continuous 24h production and processing can be realized. There is no need for manual intervention during the production process, and only the program needs to be set in advance. This greatly improves production capacity and effectively reduces labor costs. Fully automated production The method can also fully guarantee the stable quality of pet food.

The Pet Food Production Line is a very practical production line with superior performance and low price. It is very suitable for our use. With the help of this production line, we will have a broader development prospect. We also hope that we can work together. To promote the progress of science and technology together, and create a better tomorrow!